Flexographic Printing - The Pillar of Modern Printing Flexographic Printing is popularly known as Flexo Printing and has become a vital thing in modern printing. It has been defined as the most versatile and efficient in itself, adding flexo printing machines among the essentials for use in various industries, from packaging to labels to commercial printing. With high-value productions delivered onto different substrates, the flexo printing machines meet the increasing demands of business-from accuracy to productivity.

In this mega article, I will speak about the advantages, applications, technological innovations and finally why companies like UV Graphic serve in keeping pace with the rest in the race of flexo printing machines.

Advantages of Flexo Printing Machines

Flexographic printing has become well-renowned owing to the multifarious varieties of materials processed on the machine like paper, plastic, foil and corrugated cardboard. Some of these unique advantages include:

Flexibility in Substrates:

Flexo machines can print on almost any material-there is little to stop them as far as non-porous materials-like plastic films and metallic foils-are concerned. This ability permits them to take on multiple jobs-from food and beverage packaging to industrial labeling.

High-Speed Printing:

Flexo printing press is the most famous and speed-blazing solution for printing, continuous operation, very large-scale production, quick process, and hence low-cost production by time.

Environment-friendly:

Modern flexo machines are suitable for water-based and UV-curable inks, which do not consume any solvent to emit any VOC. So, they also favor green printing.

COST-EFFECTIVE:

With the innovation of the automation and ink-drying technologies, flexo printing machines reduce waste and operational costs for attaining livelihoods with the same print quality.

Flexo Printing Machine Application Areas

Flexo printing machinery is so versatile that it offers ample application in numerous industries. The following are some of the common applications:

Packaging Industry:

Flexo is probably the best type of machine for printing on flexible packaging items such as pouches, bags, and cartons. These machines are indeed proven useful to this industry because they are capable of printing on uneven surfaces and maintain their quality.

Label Printing:

Self-adhesive labels for food, beverages, and cosmetics can be created by flexo machines that really stand out. Other custom labels can be made via shrink sleeves and similar devices.

Food and Beverage Packaging:

Flexo printing is ideal for food-grade packaging, which is why many companies that apply high health and safety standards prefer this method.

Industrial and Retail Applications:

Flexo is employed to print non-porous substrates such as plastic wrap, metallic foil, and cellophane. Such printing meets the industrial and retail package needs of the market.

Corrugated Box Printing:

Flexo is the best machine for large-scale printing on corrugated boxes, such that the colors are fast for branding as well as for shipping purposes.

Technological Advancements in Flexo Printing

Flexographic printing technology has undergone great transformation with the time. Innovation continues to manufacture like UV Graphic to meet the ever-increasing demands for precision efficiency and sustainability. Some examples of such advancements are:

Automation and Digital Integration:

Automated plate loading, advanced tension control, and digital inking systems streamline the entire printing process by eliminating the time required for setup and enhancing productivity.

Servo-Driven Presses:

Modern flexo machines are equipped with servo-driven motors that promise very precise registration, even at high speeds. This cunning trick minimizes waste of material and ensures print consistency.

In-House Inspection Systems:

Such systems enable the immediate retrieval and control of quality in the workplace, thereby ensuring achievement of flawless output.

Enhanced Drying Systems:

The newest drying technologies, such as UV and LED curing, provide rapid drying of ink while holding firm with brilliant color reproduction.

Eco-friendly Printing Solutions:

Such facilities are necessary in terms of suitability with biodegradable inks-recyclable materials, which are the sign of the industry's way toward greener printing.

Sustainability in Flexo Printing

It is in print technology that environmental responsibility was leveraged first, and flexo printing machines are the ones that are really leading the way-forward with sustainable solutions. Water-based and UV-curable inks used together with energy-efficient drying systems would minimize the overall environmental footprint of printing pretty significantly.

Like UV Graphic, companies are serious about emphasizing sustainability in the designs of machines geared towards less energy consumption and minimization of waste. Eco-friendly flexo solutions now help businesses embrace worldwide sustainability endeavors while maintaining outputs of remarkable quality.

Challenges and Solutions in Flexo Printing

A flexible printing system has many advantages; however, it also faces some challenges. The most common ones are:

Plate Preparation:

It takes a lot of time to prepare plates for printing, but it is on the verge of being made easier through automation.

Color Consistency:

It is difficult to keep colors consistent for such print runs. However, this is nicely solved in today's machines with advanced inking systems and inline color management tools.

Initial Setup Costs:

Flexo machines cost more in the beginning, but through their efficiency and time, this offsets the original cost.

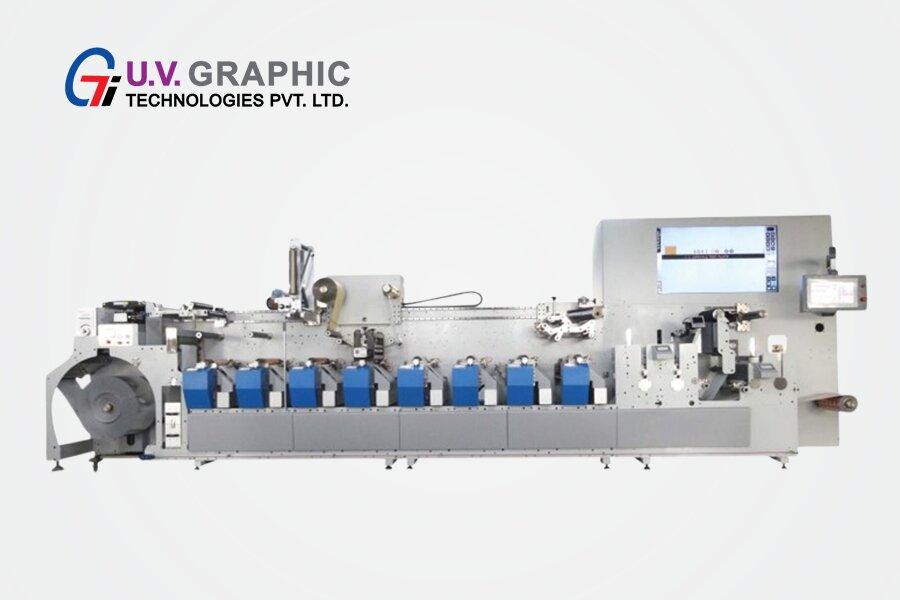

Why UV Graphic's Flexo Printing Machines Are The Best

UV Graphic as one of the leading names in the world of printing is always providing such innovative, reliable, and efficient flexo printing solutions. All of their machines are equipped with very advanced features to meet the specific needs of modern industries. Here is why UV Graphic is a preferred choice:

Precision That's Never Before:

UV Graphic flexo paradigm, while giving an extra edge, focuses on the quality of printing by ensuring that there are really defined lines with bright colors.

State-of-the-art Technology:

All features today making most of the servo-driven presses using automatic controls and inline inspection systems guarantee true efficiency with real accuracy in expected benefits.

Eco-Friendly Designs:

Put aside offering machines fitted with recyclable materials as well as water-based inks, UV Graphic is serious about sustainability.

All Support Till and Maintenance:

UV Graphic guarantees that operations will run smoothly and provide complete support from installation to maintenance.

Flexibility:

These machines can print on a wide variety of substrates and can thus also cater to many areas of application.

The Future of Flexography

Advancements in automation, sustainability, and digital addition are the drum beats which the flexo printing industry is dancing to currently and this certainly promises to take the industry a long way to great heights. Flexographic technology shall certainly keep pace with the demand and remain at the cusp of high quality, cost-effective printing needs, as it continues in business.

Modern-day pyramids are being built such as UV Graphic by turning out next-generation machines that satisfy the market's ebb-and-flow demand. A company will be able to excel within the competitive landscape, thereby sealing its breakeven for quality, efficiency, and even sustainability.

Conclusion

Flexography will become a crucial element of future societies, with all kinds of packaging, from liquids, pills, or other consumer goods, to all kinds of a replacement for traditional paper labels. Flexo has applications in virtually any industry and, according to past experience, shows unequalled versatility, speed, and precision. Thus, these machines become integrated into modern printing: packaging, labeling, etc.

UV Graphic is flexo's most forward-thinking machine builder. These machines are not introduced into the client's factory as one more machine; they are actually part of a sustainable solution addressing innovation, reliable technology, and green production. With these kinds of solutions, businesses today, tomorrow, and futures can only benefit from their properties.

It is definitely an investment in flexo machines from UV Graphics that transmits the concept of sound business sense into a step toward progress, sustainability, and, at the end of that very long tunnel, excellence in the printing industry.