Elevate Your Production with Industrial Laser Engravers

In today’s competitive manufacturing landscape, precision and efficiency are paramount. industrial engraver have emerged as essential tools for businesses looking to enhance their production capabilities. These advanced machines offer unparalleled accuracy and versatility, making them ideal for a wide range of applications. In this article, we’ll explore the benefits of industrial laser engravers, their various types, and how they can transform your operations.

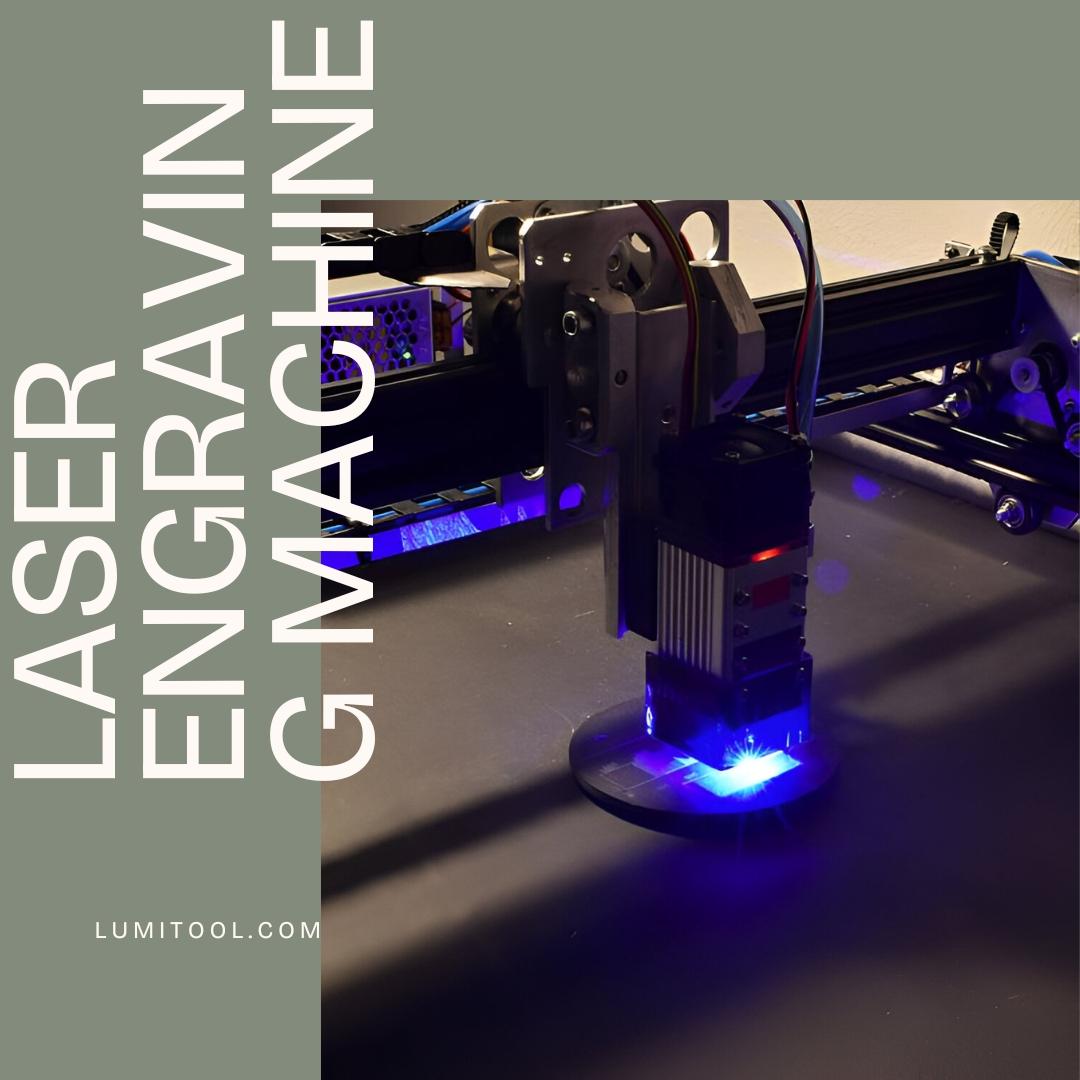

What is an Industrial Laser Engraver?

An industrial laser engraver is a specialized machine that uses high-powered laser beams to engrave or mark materials with extreme precision. This technology allows for intricate designs, logos, and text to be permanently etched onto various substrates, including metals, plastics, and glass. Unlike traditional marking methods, laser engraving is faster, cleaner, and more efficient, enabling businesses to meet the demands of modern production.

Key Benefits of Industrial Laser Engravers

1. Precision and Accuracy

One of the standout features of industrial laser engravers is their ability to produce high-quality, detailed engravings. With resolutions as fine as 0.001mm, these machines ensure that every marking is crisp and clear, making them suitable for applications that require meticulous attention to detail. This precision is crucial in industries such as electronics, automotive, and medical device manufacturing.

2. Speed and Efficiency

Industrial laser engravers are designed for high-speed operations, allowing businesses to complete marking tasks quickly. This efficiency is particularly beneficial for high-volume production environments, where time is money. The rapid processing capabilities of these machines significantly reduce turnaround times, enabling companies to meet tight deadlines without compromising quality.

3. Versatility Across Materials

These machines are capable of engraving a wide variety of materials, including metals, plastics, ceramics, and glass. This versatility makes industrial laser engravers an invaluable asset for businesses looking to diversify their product offerings. Whether you need to mark metal components or personalize plastic items, a laser engraver can handle it all.

4. Durability of Markings

The markings produced by industrial laser engravers are permanent and resistant to wear and tear. Unlike traditional engraving methods, which may fade or degrade over time, laser marks maintain their clarity and legibility, ensuring that branding and product information remain intact. This durability is particularly important for products that undergo frequent handling or exposure to harsh conditions.

5. User-Friendly Technology

Modern industrial laser engravers come equipped with intuitive software that simplifies the design and marking process. This ease of use allows even inexperienced operators to create professional-quality engravings without extensive training. The ability to customize designs quickly enhances branding efforts and improves overall efficiency.

Different Types of Industrial Laser Engravers

1. CO2 Laser Engravers

CO2 laser engravers are widely used in various industries due to their ability to engrave a broad range of materials, including wood, acrylic, and glass. They operate by discharging infrared light through a carbon dioxide gas mixture, producing deep engravings and fine details. These machines are known for their ease of use and low maintenance requirements, making them a popular choice for many applications.

2. Fiber Laser Engravers

Fiber laser engravers have gained popularity for their efficiency and versatility. Unlike CO2 lasers, fiber lasers use a solid-state source to generate a light beam, making them ideal for marking metals and other hard materials. They offer high-speed engraving and require minimal maintenance, making them an excellent investment for businesses focused on high-accuracy tagging and flexibility.

3. YAG Laser Engravers

YAG (Yttrium Aluminum Garnet) lasers are known for their ability to cut and engrave metals with precision. They emit light in the 1064 nanometer wavelength range, making them suitable for various materials, including stainless steel and some plastics. YAG lasers are efficient and have low maintenance needs, making them a reliable choice for industrial applications.

Applications of Industrial Laser Engravers

Industrial laser engravers find applications in a variety of sectors:

- Automotive: Engraving VINs, logos, and safety information on vehicle components.

- Electronics: Marking PCBs and casings with serial numbers and barcodes for traceability.

- Medical Devices: Engraving surgical instruments with unique identifiers for compliance.

- Jewelry: Creating intricate designs and personalized engravings on precious metals.

- Aerospace: Marking parts with QR codes and identification numbers for maintenance tracking.

Conclusion

Investing in an industrial laser engraver can significantly enhance your business operations by providing precision, speed, and versatility. With the ability to mark various materials and create durable markings, these machines are essential tools for any modern manufacturer. By embracing this innovative technology, you can elevate your products, improve customer satisfaction, and gain a competitive edge in the market.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Jogos

- Gardening

- Health

- Início

- Literature

- Music

- Networking

- Outro

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness

- IT, Cloud, Software and Technology