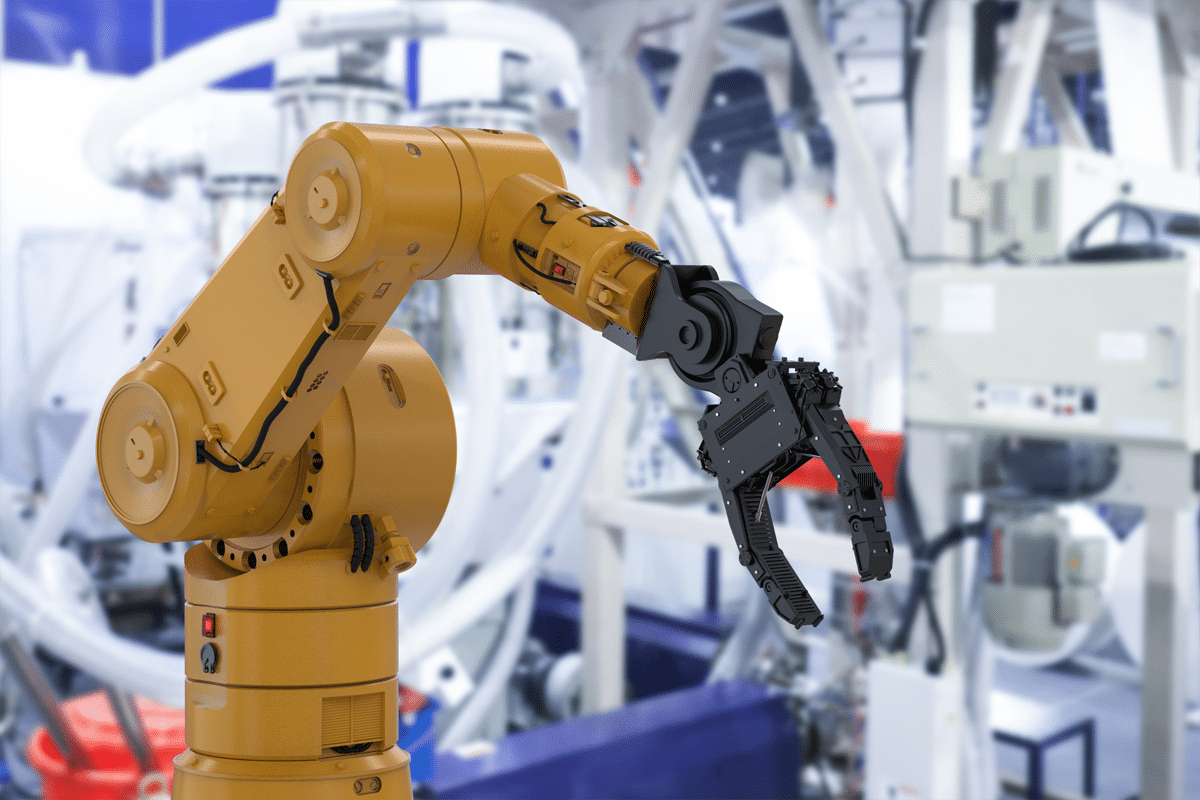

Robotic Arms Market Growth Challenges: Overcoming Technical, Financial, and Adoption Barriers in Automation Expansion

The robotic arms market growth challenges are a series of obstacles that slow down the pace at which robotic arms can be adopted and integrated across various industries. Although robotic arms offer transformative potential to improve manufacturing efficiency, precision, and safety, multiple factors constrain their widespread growth. Understanding these challenges is essential for businesses and stakeholders aiming to harness robotic automation effectively.

Technical Complexity and Skill Shortages

One of the foremost growth challenges in the robotic arms market is the technical complexity involved in deploying and operating these advanced systems. Robotic arms often require sophisticated programming, precise calibration, and regular maintenance, which demands a highly skilled workforce.

Many industries, especially in developing regions, face a shortage of engineers and technicians proficient in robotics, automation, and related software tools. This skills gap limits companies’ ability to deploy robotic arms efficiently and hinders their maintenance and optimization after installation.

Furthermore, integrating robotic arms with existing machinery, software systems, and industrial networks adds another layer of technical difficulty. Ensuring seamless communication between robotic arms and other automated systems is crucial for operational efficiency but remains a complex challenge for many enterprises.

High Capital Investment and Operational Costs

The high initial investment required to procure and install robotic arms is a significant barrier to market growth. Robotic arms are expensive to purchase, and the associated costs for installation, integration, training, and maintenance can be substantial.

For many small and medium enterprises (SMEs), these upfront costs are prohibitive, delaying or preventing the adoption of robotic automation. Moreover, operational expenses such as periodic software updates, system calibration, and part replacements add to the ongoing financial commitment.

This high capital requirement slows down the market growth, especially in industries with tight profit margins or in emerging economies where access to finance may be limited.

Workforce Resistance and Labor Market Concerns

Growth in the robotic arms market is often slowed by resistance from the existing workforce. Employees and labor organizations frequently view automation with suspicion, fearing job losses and reduced labor demand.

This cultural resistance can delay investment decisions and complicate implementation projects. Companies need to manage workforce concerns by fostering awareness that robotic arms often complement human labor by taking on repetitive, hazardous, or physically demanding tasks rather than fully replacing workers.

Additionally, retraining and upskilling employees to work alongside robotic systems can be resource-intensive but is necessary to alleviate resistance and maximize the benefits of automation.

Integration and Compatibility Issues

Another significant growth challenge is the integration of robotic arms into established industrial environments. Many factories and facilities operate with legacy machinery and software, which may not be immediately compatible with modern robotic arms.

The process of retrofitting or upgrading these systems to work harmoniously can be complex and costly. Incompatible technologies lead to inefficiencies, increased downtime during installation, and sometimes require businesses to overhaul entire production lines to accommodate new automation.

Without standardized protocols and flexible robotic solutions, integration challenges remain a persistent growth inhibitor.

Safety and Regulatory Compliance

Safety is a critical concern that affects the growth of the robotic arms market. Robotic arms working alongside humans must comply with strict safety standards and regulations to prevent workplace accidents.

Although collaborative robots (cobots) have made working near robots safer, many traditional robotic arms still require physical barriers or safety cages, which limit their operational flexibility and add to installation costs.

Navigating the complex regulatory environment can delay project approvals and increase costs, particularly in highly regulated industries like pharmaceuticals, food processing, and healthcare.

Cybersecurity Vulnerabilities

As robotic arms become more connected through industrial networks and the Internet of Things (IoT), cybersecurity becomes a vital challenge. Connected robotic arms are potential targets for cyberattacks that can disrupt production, cause safety hazards, or lead to data breaches.

Ensuring robust cybersecurity protections involves additional investment in hardware, software, and personnel training. Companies that underestimate these needs risk facing operational and reputational damage, which can slow broader market growth.

Customization and Flexibility Constraints

Many robotic arms are designed for specific, repetitive tasks and may lack the flexibility required for diverse or frequently changing production environments. This rigidity can be a barrier for industries that need adaptable automation solutions capable of handling varying product types, batch sizes, or custom orders.

Without customizable and modular robotic arms, businesses may hesitate to invest heavily in automation for fear of reduced efficiency when production demands shift.

Economic and Market Uncertainties

The broader economic environment also impacts the robotic arms market growth. During economic downturns or periods of market instability, companies tend to postpone or scale back investments in automation technology.

In emerging markets, slower industrial development and infrastructure challenges further delay robotic arm adoption. Trade tensions and supply chain disruptions also introduce uncertainties that can restrict market expansion.

Environmental and Ethical Considerations

Environmental concerns about the energy consumption and electronic waste associated with robotic arms are growing. Companies face pressure to adopt sustainable manufacturing processes, which may complicate or slow down robotic arm deployments.

Ethical questions around workforce impacts and the degree of automation also affect acceptance and regulatory scrutiny, potentially influencing market growth trajectories.

Conclusion

The robotic arms market growth challenges are multifaceted, encompassing technical, financial, social, and regulatory barriers. Technical complexity, high costs, workforce resistance, integration difficulties, and cybersecurity risks collectively restrain the pace at which robotic arms can revolutionize industries.

To overcome these challenges, businesses must invest in workforce training, develop flexible and cost-effective robotic solutions, and prioritize safety and cybersecurity. Addressing these issues will pave the way for accelerated adoption, unlocking the full potential of robotic arms in transforming manufacturing and beyond.

Despite these hurdles, the long-term outlook remains optimistic as innovation continues, and industries increasingly recognize the indispensable value of robotic automation for future competitiveness and efficiency.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- الألعاب

- Gardening

- Health

- الرئيسية

- Literature

- Music

- Networking

- أخرى

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness

- IT, Cloud, Software and Technology