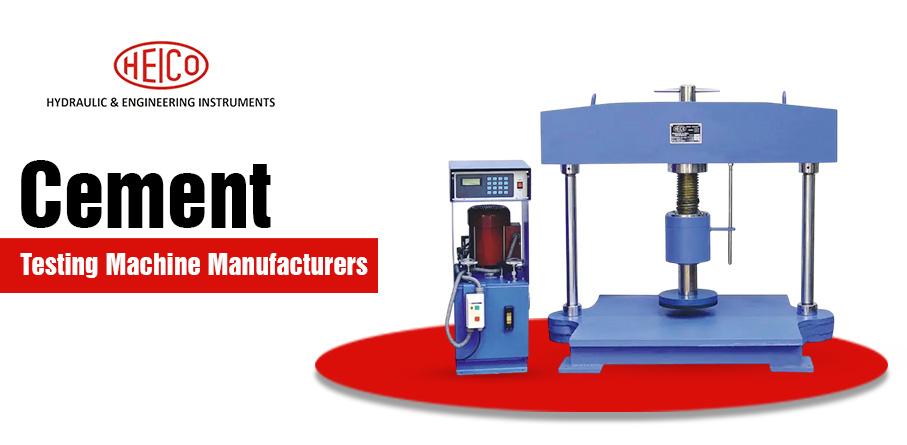

Enhancing Construction Quality with Advanced Cement Testing Machines

In today’s construction industry, the strength and reliability of materials play a crucial role in building long-lasting structures. Cement testing machines are essential tools that help ensure cement meets industry standards and project requirements. For civil engineers, construction professionals, and lab technicians, understanding how to use these machines effectively can significantly enhance structural quality.

Importance of Cement Testing in Construction

Cement is the backbone of most construction projects. Any variation in its quality can lead to weak structures, safety hazards, and costly repairs. This is why cement testing tools are vital before using cement in any construction work.

Testing helps verify properties like compressive strength, setting time, fineness, and consistency. By identifying defects early, engineers can make better decisions about material selection and usage, ensuring a solid foundation for every build.

Advanced Cement Testing Machines and Their Functions

Modern advanced cement testing equipment is designed to deliver accurate, reliable results with minimal human error. These machines are widely used in laboratories and onsite for routine checks and research.

Here are a few commonly used cement testing machines and their core functions:

-

Compression Testing Machine: Measures the compressive strength of cement cubes or mortar specimens.

-

Vicats Apparatus: Tests the setting time and consistency of cement paste.

-

Blaine Air Permeability Apparatus: Determines the fineness of cement powder.

-

Le Chatelier Apparatus: Measures the soundness or expansion of cement.

With automation and digital features, these cement quality testing machines offer better precision, data tracking, and faster turnaround times—critical factors in today’s fast-paced construction industry.

How Testing Improves Structural Quality

Incorporating cement testing machines into your quality control process has multiple benefits. First, it ensures that the cement meets relevant IS or ASTM standards. Second, it identifies inconsistencies in batches, reducing the risk of failure during or after construction.

Regular testing boosts project confidence by minimizing uncertainties. For large infrastructure developments, using advanced cement testing equipment allows teams to optimize mix designs, lower material waste, and increase the lifespan of the structure.

Moreover, it aids in compliance with government and safety regulations, helping avoid penalties and project delays.

Choosing the Right Cement Testing Equipment

When selecting cement testing tools for your lab or construction site, consider the following:

-

Purpose: Identify which tests you need—strength, fineness, or setting time.

-

Accuracy and Compliance: Choose equipment that meets national and international standards.

-

Ease of Use: Look for digital interfaces, automated features, and compact designs.

-

After-Sales Support: Reliable service and calibration support are crucial for consistent results.

Investing in the right cement testing machines not only ensures accuracy but also helps improve overall construction quality.

Conclusion

As construction projects become more demanding, quality assurance is no longer optional—it’s essential. Cement testing machines play a key role in maintaining high construction standards. By using advanced cement testing equipment, professionals can ensure durability, safety, and long-term performance of their projects. Whether you’re building bridges, homes, or skyscrapers, testing your cement with the right tools is a smart, future-proof move.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Juegos

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness

- IT, Cloud, Software and Technology