CNC Machining Services: Precision, Efficiency, and Innovation in Modern Manufacturing

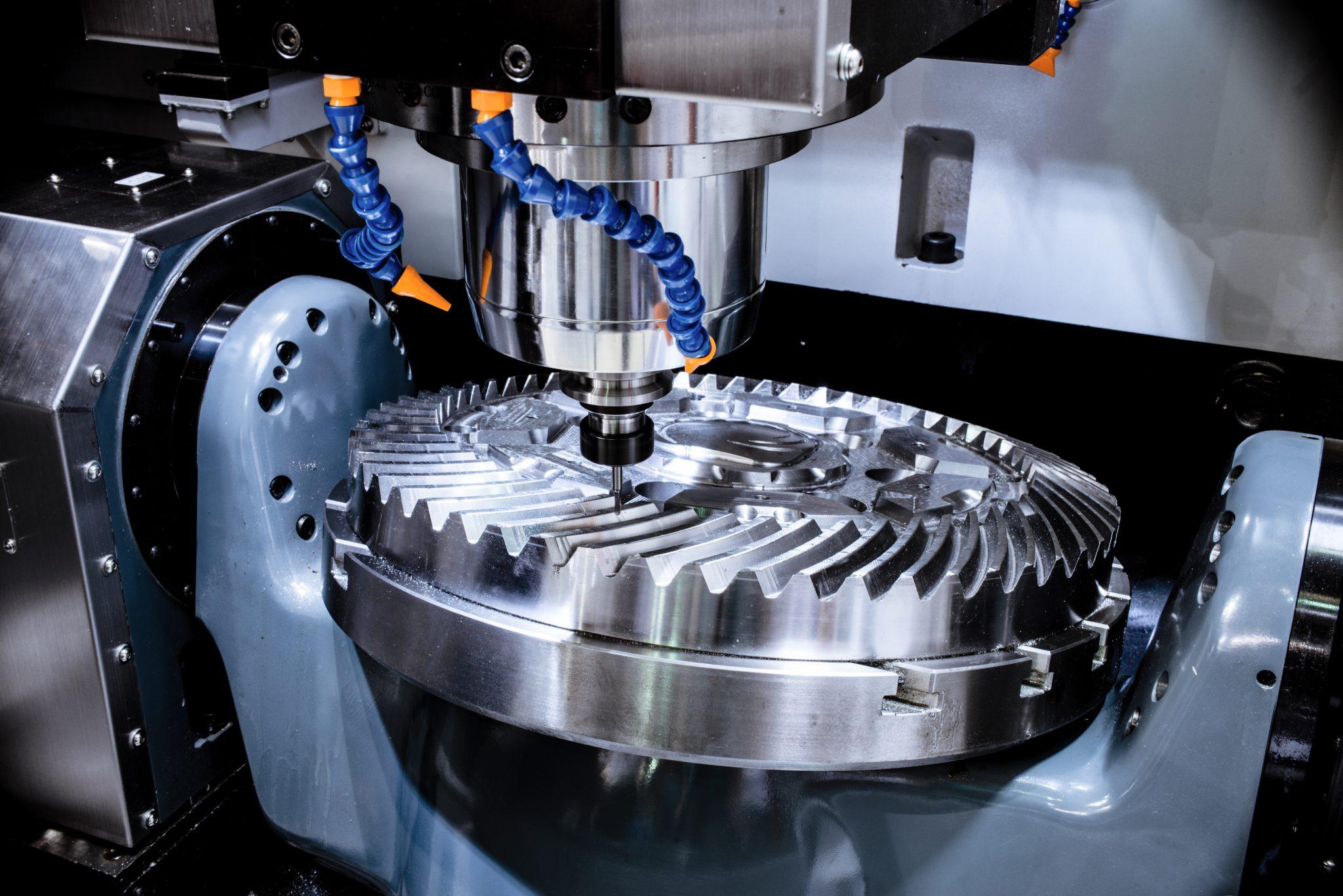

In the realm of modern manufacturing, precision and efficiency are not just desired — they are essential. One of the most revolutionary advancements that support this demand is CNC machining services. CNC, short for Computer Numerical Control, refers to the use of computers to control machine tools such as lathes, mills, routers, and grinders. These services have transformed manufacturing processes by enhancing accuracy, reducing manual labor, and enabling complex part production with remarkable speed and consistency.

What Are CNC Machining Services?

CNC machining services encompass the use of automated, computer-controlled machines to produce parts and components from raw materials. These machines interpret a CAD (Computer-Aided Design) file and convert it into instructions, or G-code, which direct the movements and operations of the machine tools. The result is a precisely crafted component that adheres closely to the original design specifications.

These services are widely used across industries, including aerospace, automotive, medical, electronics, and industrial machinery, due to their ability to deliver high-quality parts with tight tolerances.

Types of CNC Machines

There are several types of machines used in CNC machining services, each with its specific applications:

-

CNC Milling Machines

These machines use rotating cutting tools to remove material from a workpiece. They are ideal for producing complex shapes and intricate details. -

CNC Lathes

Lathes rotate the workpiece while a stationary cutting tool shapes it. These are perfect for cylindrical parts such as shafts, bolts, and bushings. -

CNC Routers

Commonly used in woodworking, plastic, and softer metal applications, routers operate similarly to milling machines but at higher speeds. -

CNC EDM (Electrical Discharge Machining)

EDM uses electrical sparks to erode material and is suitable for hard metals or components with very fine details. -

CNC Plasma Cutters

These machines use a high-powered plasma torch to cut through metal and are often employed in fabrication and construction.

Each of these machines plays a critical role in expanding the scope and capability of CNC machining services.

Advantages of CNC Machining Services

CNC machining services provide a host of benefits that traditional manufacturing methods cannot match. Below are some of the most significant advantages:

1. Unmatched Precision and Accuracy

CNC machines can operate within tolerances of a few microns, making them ideal for industries where exact measurements are crucial.

2. Repeatability

Once a design is programmed into a CNC machine, it can reproduce the same part hundreds or thousands of times with no loss of quality.

3. Efficiency and Speed

Automated processes significantly reduce production times and minimize human error, resulting in quicker project completion.

4. Complex Capabilities

CNC machines can produce intricate shapes and features that would be difficult, if not impossible, to achieve manually.

5. Reduced Waste

With precise control over material removal, CNC machining results in less waste, saving both raw materials and costs.

6. Scalability

From one-off prototypes to full-scale production runs, CNC machining services are scalable to fit any manufacturing need.

Applications Across Industries

CNC machining services are integral to numerous sectors, providing solutions that range from simple components to highly specialized parts.

Aerospace

Precision is paramount in aerospace. CNC machining ensures the structural integrity and reliability of components such as turbine blades, engine housings, and landing gear parts.

Automotive

From gearboxes to custom engine parts, the automotive industry benefits from CNC machining’s speed and precision in both prototyping and mass production.

Medical

Medical devices and implants require biocompatibility and exact measurements. CNC machining produces surgical tools, bone plates, and orthopedic implants with precision.

Electronics

CNC machining is used to manufacture small, intricate components like heat sinks, housings, and connectors for electronic devices.

Defense

Military equipment requires robust, durable parts. CNC machining delivers components that meet stringent safety and performance standards.

CNC Machining Services for Prototyping

One of the most valuable applications of CNC machining services is in prototyping. Rapid prototyping with CNC allows manufacturers to test and refine designs before full production. CNC prototypes offer:

-

High material versatility (metal, plastic, composites)

-

Faster turnaround times than tooling-dependent methods

-

Realistic models for mechanical testing

Prototyping ensures that final products meet functional requirements and customer expectations without expensive revisions later.

Materials Used in CNC Machining

CNC machining supports a wide range of materials, giving manufacturers flexibility in design and application. Common materials include:

-

Metals: Aluminum, steel, brass, copper, titanium

-

Plastics: ABS, nylon, polycarbonate, PEEK

-

Composites: Carbon fiber-reinforced polymers

-

Foam and wood: For model-making or non-industrial use

The choice of material depends on factors such as strength, weight, corrosion resistance, and cost.

Selecting a CNC Machining Service Provider

Choosing the right provider for CNC machining services is essential for achieving desired results. Consider the following factors:

-

Capabilities and Equipment

Ensure the provider has the right machines and technology for your project’s specifications. -

Experience and Expertise

A skilled team with experience in your industry can guide you through material selection, design optimization, and production efficiency. -

Quality Control

Look for providers with ISO certifications or similar quality standards to ensure consistent results. -

Lead Times

Check turnaround times to match your project schedule. -

Customer Support

Responsive communication and technical support are key to a successful collaboration.

Trends Shaping the Future of CNC Machining Services

The future of CNC machining services is being shaped by several emerging trends:

-

Automation and Robotics

Integration with robotic arms and conveyors enhances automation and efficiency. -

Smart Manufacturing and IoT

CNC machines are now integrated into smart systems that offer real-time monitoring, predictive maintenance, and data analytics. -

Sustainable Manufacturing

Energy-efficient machines and recycling-friendly materials are becoming more prevalent. -

Hybrid Manufacturing

Combining CNC machining with 3D printing allows for faster production and more complex part geometries.

Conclusion

CNC machining services have revolutionized modern manufacturing by delivering unmatched precision, efficiency, and flexibility. Whether you are a startup developing prototypes or a global enterprise scaling up production, CNC technology offers reliable solutions tailored to your needs. By leveraging computer-controlled machinery, industries can achieve faster turnaround times, higher quality products, and lower production costs.

As technology continues to advance, CNC machining will remain a cornerstone of innovation — driving progress in fields from aerospace to medical, and everything in between.

Ready to boost your production with precision machining? CNC machining services could be your next competitive advantage.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Spellen

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness

- IT, Cloud, Software and Technology