The Advantages and Applications of 3003 H14 Aluminum Coil

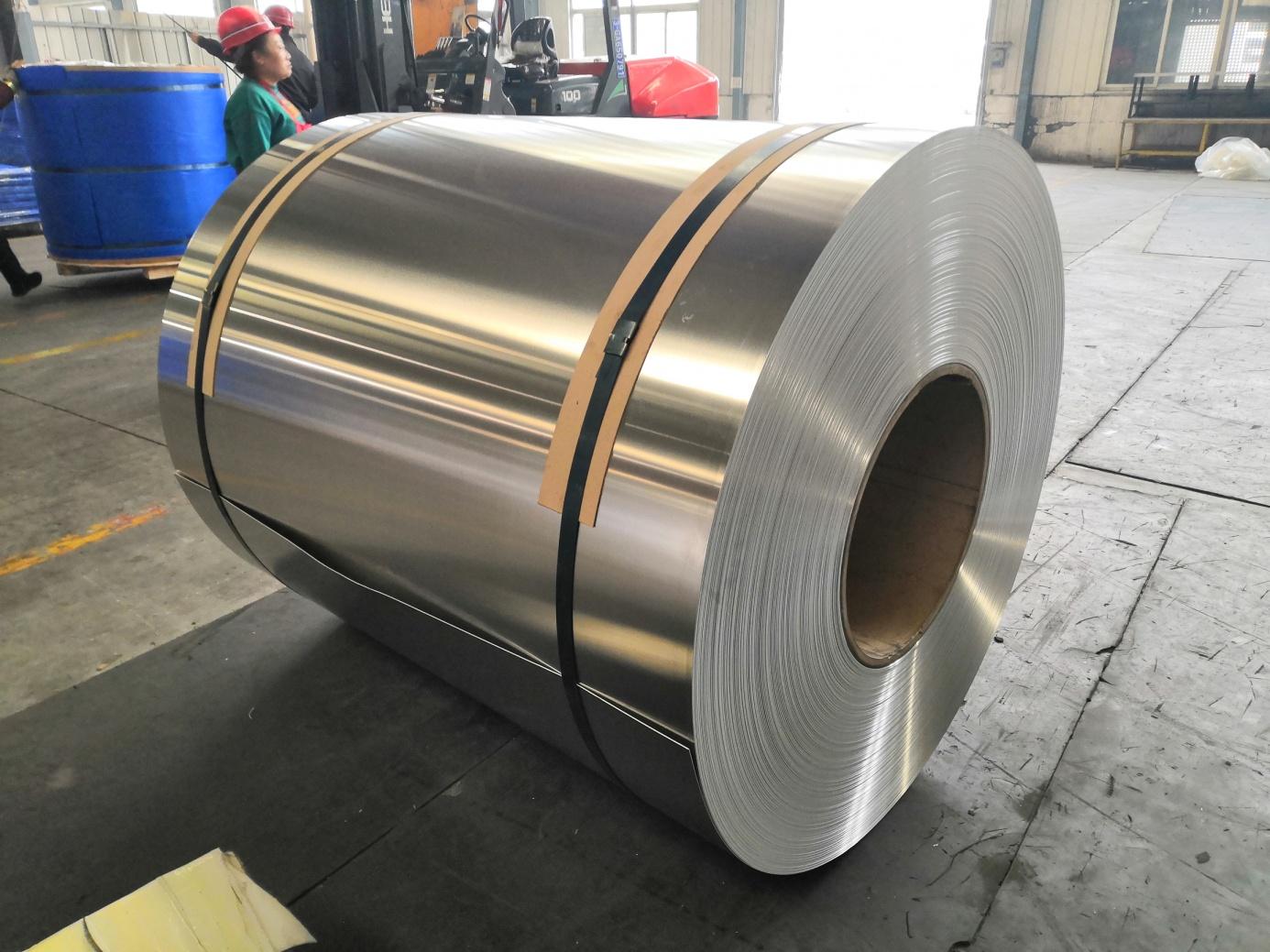

Aluminum coils are widely used in various industries due to their excellent properties such as lightweight, corrosion resistance, and high thermal conductivity. One popular grade of aluminum coil is 3003 H14, which offers a unique combination of strength and formability. In this article, we will explore the advantages and applications of 3003 H14 Aluminum Coil, highlighting its professional and authoritative use in various industries.

Advantages of 3003 H14 Aluminum Coil

Strength and Formability: 3003 H14 aluminum coil is known for its impressive strength and formability. The H14 temper indicates that the aluminum has been strain-hardened and partially annealed, resulting in improved mechanical properties. This makes it suitable for various applications that require both strength and formability, such as roofing, truck/trailer bodies, and signage.

Corrosion Resistance: Aluminum is naturally resistant to corrosion, and 3003 alloy further enhances this property. The addition of manganese to the alloy composition provides increased resistance to atmospheric corrosion. This makes 3003 H14 aluminum coil an ideal choice for outdoor applications, including building facades, gutters, and downspouts.

Weldability: 3003 H14 aluminum coil is highly weldable, allowing for easy joining with other aluminum components. This makes it a preferred material in the fabrication of various structures, including automotive parts, heat exchangers, and storage tanks.

Versatility: Due to its excellent formability, 3003 H14 aluminum coil can be easily shaped and bent into different profiles, making it highly versatile. It can be used for roll forming, stamping, and deep drawing processes, enabling the production of complex components and intricate designs.

Applications of 3003 H14 Aluminum Coil

Building and Construction: The combination of strength, formability, and corrosion resistance makes 3003 H14 aluminum coil a popular choice in the building and construction industry. It is commonly used for roofing, cladding, and architectural elements, where durability and aesthetic appeal are crucial.

Transportation: Aluminum coils find extensive use in the transportation sector, and 3003 H14 is no exception. Its lightweight nature contributes to fuel efficiency in vehicles while maintaining structural integrity. It is employed in the manufacturing of truck/trailer bodies, bus frames, and automotive panels.

Packaging: The formability and weldability of 3003 H14 aluminum coil make it suitable for packaging applications. It is commonly used in the production of cans, lids, and closures for the food and beverage industry, ensuring product freshness and safety.

Electrical and Electronics: Aluminum's excellent thermal conductivity and electrical properties make it a preferred material in the electrical and electronics industry. 3003 H14 aluminum coil is utilized in heat sinks, power transmission lines, and electronic enclosures, providing efficient heat dissipation and electrical insulation.

Industrial Equipment: Various industrial equipment and machinery benefit from the advantages of 3003 H14 aluminum coil. It is used in the fabrication of storage tanks, heat exchangers, and ventilation systems, where its corrosion resistance and weldability are highly advantageous.

Conclusion

In conclusion, 3003 H14 aluminum coil offers a wide range of advantages and applications. Its strength, formability, corrosion resistance, weldability, and versatility make it a preferred choice in various industries, including building and construction, transportation, packaging, electrical and electronics, and industrial equipment. With its professional and authoritative use, 3003 H14 aluminum coil continues to demonstrate its value in numerous applications, contributing to the advancement of modern industries.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Jeux

- Gardening

- Health

- Domicile

- Literature

- Music

- Networking

- Autre

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness

- IT, Cloud, Software and Technology