Explosion-Proof Electric Wafer Type Butterfly Valves: Reliable Flow Control for Hazardous Environments

Introduction

We are a leading control valve manufacturer in China, delivering high-quality valves and control actuators customized to meet a wide range of industrial requirements.

In industrial environments where flammable gases, vapors, or combustible dust are present, safety is non-negotiable. Explosion-proof electric wafer type butterfly valves are engineered to meet this demand—providing secure, automated flow control in potentially explosive atmospheres. These valves combine electrical safety with robust mechanical design, ensuring reliable performance while minimizing ignition risks.

They are essential in high-stakes sectors such as petrochemicals, mining, oil & gas, and pharmaceuticals, where strict compliance with explosion-proof standards is critical for protecting both people and infrastructure.

Key Benefits of Explosion-Proof Electric Wafer Type Butterfly Valves

1. Enhanced Safety for Hazardous Zones

The most important feature of these valves is their certified explosion-proof electric actuator, designed to prevent electrical sparks or thermal ignition sources. They comply with international standards (such as ATEX, IECEx) for use in Zone 1 and Zone 2 hazardous areas, making them indispensable in high-risk environments.

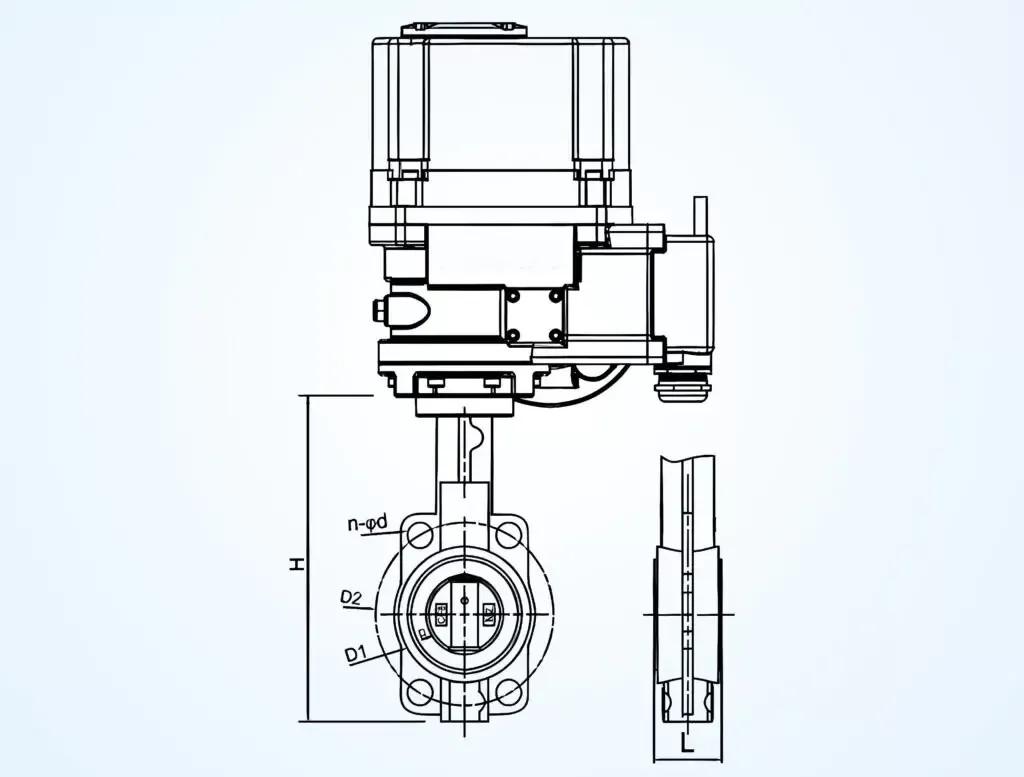

2. Compact and Lightweight Design

Thanks to the wafer type construction, these valves offer a space-saving, low-profile form factor that fits between pipeline flanges without requiring additional supports or complex installation. This design minimizes system weight and simplifies integration, especially in areas with spatial or load constraints.

3. Simplified Installation and Maintenance

Installation is straightforward—these valves are “sandwiched” between two flanges using standard bolts. Maintenance is also simplified by the modular design, allowing the actuator or internal components to be serviced or replaced without removing the entire valve assembly.

4. Accurate and Automated Flow Control

Equipped with electric actuators, these valves offer precise modulation of flow rates for liquids, gases, or vapors. Integration with PLCs or DCS systems enables remote operation, diagnostics, and feedback, reducing manual intervention and supporting process automation.

5. Durable Construction for Harsh Conditions

Built from corrosion-resistant materials such as stainless steel or coated carbon steel, the valve body and disc are engineered to handle aggressive media, high pressures, and wide temperature ranges—ensuring long service life and minimal downtime.

Application Areas

▶ Petrochemical Industry

Used in refineries, chemical plants, and gas processing units to manage the flow of flammable substances. The explosion-proof actuator ensures safe, compliant operation even in volatile environments.

▶ Mining Operations

Essential for fluid handling in underground and surface mining, where methane and other explosive gases are present. These valves support both ventilation and process fluid control safely.

▶ Pharmaceutical Manufacturing

In facilities where reactive or flammable solvents are used, explosion-proof valves ensure clean, controlled, and safe fluid handling in batch reactors, clean rooms, and storage systems.

▶ Oil and Gas Sector

Deployed in upstream and downstream operations—from wellheads to pipeline manifolds and tank farms—these valves offer safe shut-off and flow control for crude oil, natural gas, and refined products.

▶ Industrial Process Plants

Used in chemical, paint, textile, and other processing environments to prevent ignition in systems that manage combustible fluids or vapors. The valve’s high-performance sealing ensures leak-free shutoff.

Conclusion

Explosion-proof electric wafer type butterfly valves represent a critical solution for controlling process flow in high-risk environments. Their compact form, rugged construction, and advanced electric actuation make them an essential choice for any operation requiring both automation and intrinsic safety.

As industries evolve toward more automated and safer systems, these valves provide the perfect balance of control, safety, and reliability. From petrochemical plants to pharmaceutical clean rooms, they stand as a frontline defense against explosions—ensuring safe, uninterrupted operations in even the most hazardous applications.Know more about Google SEO Directory

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Games

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness

- IT, Cloud, Software and Technology