Eccentric Plug Control Valves: Design, Functionality, and Industrial Applications

Eccentric Plug Control Valves: Design, Functionality, and Industrial Applications

Introduction

We are a leading control valve manufacturer in China, providing high-performance valves and control actuators designed to meet a wide range of industrial applications.

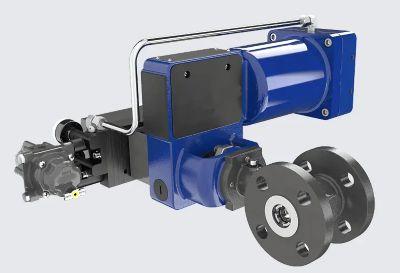

Control valves are integral to fluid regulation in industrial systems, enabling precise control of flow rate, pressure, and direction. Among various types, eccentric plug control valves stand out for their unique off-center plug design, which enhances sealing, minimizes wear, and ensures reliable operation under harsh conditions.

Engineered for challenging applications involving abrasive fluids, slurries, and viscous media, eccentric plug valves offer superior performance where conventional valve types often fall short. This article provides an in-depth overview of the working principle, design features, application range, and performance advantages of eccentric plug control valves—offering insights for engineers, maintenance personnel, and system designers.

What Is an Eccentric Plug Control Valve?

An eccentric plug control valve is a type of rotary, quarter-turn valve designed for precise modulation of fluid flow. Unlike traditional plug valves, this design incorporates an eccentrically mounted plug, which rotates away from the seat during opening to minimize seat contact and reduce operating torque and wear.

Key Design Elements:

-

Eccentric Plug: Offset from the centerline to allow frictionless disengagement from the seat during opening and closing.

-

Heavy-Duty Construction: Commonly made from corrosion-resistant and wear-resistant materials, including stainless steel, duplex steel, and alloy coatings.

-

Tight Shutoff Capability: Offers reliable sealing with ANSI Class IV (hard seal) or Class VI (soft seal) ratings.

-

Self-Cleaning Design: Continuous rotation dislodges debris, preventing buildup and blockages.

These features make the eccentric plug valve suitable for a wide range of demanding process environments.

Working Principle of Eccentric Plug Control Valves

The valve operates on a quarter-turn rotary motion, with a design that ensures efficient sealing and flow control with minimal friction.

1. Sealing in the Closed Position

When fully closed, the plug aligns against the seat under uniform pressure, creating a tight seal. The eccentric geometry ensures that contact occurs only at the final moment of closure, preventing galling and prolonging seat life.

2. Opening Motion

As the actuator or hand lever rotates the plug 90 degrees, the offset plug disengages from the seat with a lifting motion, allowing flow to resume through the valve body with reduced torque and wear.

3. Flow Regulation

Precise modulation is achieved by controlling the plug’s rotation angle. The valve offers excellent linear control characteristics with minimal turbulence and pressure drop due to its streamlined flow path.

4. Self-Cleaning Operation

The plug’s movement continuously sweeps the seat surface, dislodging solids and reducing fouling—especially beneficial in slurry or wastewater systems.

Key Features and Advantages

Eccentric plug control valves deliver several advantages over globe, ball, and standard plug valves, especially in severe service environments.

| Feature | Benefit |

|---|---|

| Tight Shutoff | Meets ANSI B16.104 Class IV (metal seat) or Class VI (soft seat) standards. |

| Low Operating Torque | Offset design reduces friction, easing actuation. |

| Self-Cleaning Action | Disc rotation clears debris from the sealing area. |

| Long Seat Life | Protected from erosion in abrasive service. |

| Split Spool Design | Allows material customization for specific media. |

| One-Piece Stem | Provides stability, accuracy, and prevents deflection. |

| Anti-Fly-Out Stem | Ensures safety by preventing stem ejection in high-pressure systems. |

| Service-Friendly | Simplified construction supports fast disassembly and maintenance. |

Common Applications

Eccentric plug valves are used in industries where reliability and durability are paramount:

1. Oil & Gas

-

Suitable for high-pressure crude, refined products, or corrosive natural gas.

-

Offers bubble-tight shutoff with durable metallurgy.

2. Chemical Processing

-

Handles aggressive chemicals, acids, and abrasive slurries.

-

Corrosion-resistant alloys ensure safe, long-term operation.

3. Power Generation

-

Controls boiler feedwater, cooling loops, and condensate systems.

-

Withstands high-temperature and high-pressure steam conditions.

4. Water & Wastewater Treatment

-

Regulates sludge, raw sewage, and treated water.

-

Self-cleaning design resists clogging from solids and biofilm.

Performance Advantages Over Conventional Valves

1. Higher Flow Efficiency

-

Straight-through design minimizes pressure loss and flow turbulence.

-

Superior Cv values improve controllability.

2. Improved Wear Resistance

-

Plug disengages before rotating, reducing seat erosion and galling.

-

Ideal for abrasive or slurry applications.

3. Lower Maintenance Costs

-

Self-cleaning mechanism limits manual cleaning intervals.

-

Fewer internal components simplify maintenance procedures.

4. Enhanced Safety and Reliability

-

Anti-blowout stem shoulder protects against catastrophic failure.

-

ANSI-compliant sealing ensures environmental and process safety.

How to Select the Right Eccentric Plug Valve

Choosing the correct valve involves evaluating multiple factors to match the process conditions:

1. Material Compatibility

-

Use stainless or duplex steel for corrosive fluids.

-

Opt for tungsten or chromium carbide overlays in abrasive environments.

2. Pressure and Temperature Ratings

-

Ensure valve meets maximum operating pressure (PN/Class) and temperature limits.

-

Consider reinforced body materials for extreme conditions.

3. Flow and Sizing

-

Match valve size (DN/NPS) to line size for minimal pressure drop.

-

Use flow coefficient (Cv) to optimize control performance.

4. Actuation Requirements

-

Manual actuation for low-cycle systems.

-

Pneumatic or electric actuators for automated or high-frequency use.

5. Sealing Requirements

-

Choose soft-seat (PTFE, elastomers) for tight shutoff.

-

Use metal-seat for high-temperature or abrasive services.

6. Maintenance Access

-

Select valves with top-entry or split-body access for easy servicing.

-

Self-cleaning features reduce clogging risk and cleaning frequency.

Conclusion

Eccentric plug control valves offer an ideal solution for industries requiring precise control, long service life, and low maintenance in challenging process environments. Their unique geometry reduces friction, enhances sealing performance, and resists wear—making them superior to conventional valve types in applications involving slurries, corrosive chemicals, and viscous media.

By carefully selecting the right valve configuration and materials, operators can achieve dependable flow control, lower operating costs, and improved safety in their industrial systems.

For professionals in oil & gas, chemical processing, power, or water treatment, incorporating eccentric plug control valves is a smart investment in long-term system performance and operational excellence.Learn more about Google SEO.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Games

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness

- IT, Cloud, Software and Technology