How Ultrasonic Oxidative Desulfurization Plants Are Changing the Refining Industry

The refining industry has long relied on hydrodesulfurization (HDS) as the primary process for reducing sulfur content in fuels. While effective, HDS requires high temperatures, high pressure, and significant hydrogen consumption, making it both costly and environmentally burdensome. As global sulfur regulations tighten, refiners are increasingly looking for alternatives that offer cleaner, more efficient results. One such innovation is ultrasonic oxidative desulfurization (UOD)—a technology rapidly gaining traction for its ability to reshape the future of refining.

At its core, ultrasonic oxidative desulfurization combines ultrasound cavitation with selective oxidants to break down refractory sulfur compounds such as dibenzothiophene (DBT). Unlike conventional hydrodesulfurization, UOD does not require extreme operating conditions. Instead, ultrasonic waves generate microscopic bubbles that collapse violently, creating localized hotspots of high temperature and pressure. These micro-explosions accelerate oxidation reactions, converting sulfur compounds into polar sulfones and sulfoxides, which can be easily separated from the fuel via extraction or adsorption.

This approach offers several game-changing advantages for refiners:

Lower Operational Costs

UOD operates at near-ambient temperatures and pressures, drastically reducing energy requirements compared to HDS. The absence of hydrogen consumption not only cuts expenses but also alleviates logistical challenges associated with hydrogen supply and storage.

Compatibility with Refractory Sulfur Compounds

Traditional HDS struggles to remove sterically hindered sulfur species like 4,6-dimethyldibenzothiophene. UOD, on the other hand, excels at targeting these stubborn molecules, achieving ultra-low sulfur levels in compliance with international fuel standards.

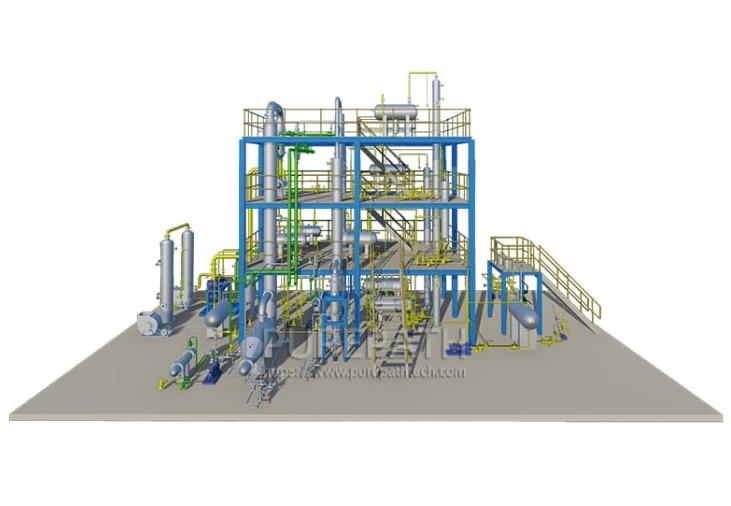

Scalability and Integration

Ultrasonic desulfurization units can be integrated into existing refinery infrastructure as a complementary or polishing step. This flexibility allows refiners to adapt gradually, avoiding large upfront investments in new facilities.

Environmental Sustainability

By eliminating the need for high hydrogen consumption and lowering energy use, UOD reduces greenhouse gas emissions. Additionally, the process minimizes the formation of byproducts and enables more sustainable handling of oxidized sulfur residues.

The refining industry is under increasing pressure to reduce emissions and align with net-zero targets. Ultrasonic oxidative desulfurization represents a significant stride in that direction. Early adopters of UOD technology are finding not only regulatory compliance but also long-term competitiveness through reduced operating costs and cleaner outputs.

Looking ahead, advancements in ultrasonic transducer design, catalyst development, and solvent recovery are expected to further improve the efficiency and scalability of these plants. As the industry balances profitability with sustainability, ultrasonic oxidative desulfurization could transition from a niche innovation to a mainstream refining solution.

In short, ultrasonic oxidative desulfurization is more than just a new tool—it’s a transformative approach that redefines how refiners meet environmental standards, optimize operations, and prepare for a future of cleaner fuels.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Jocuri

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Alte

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness

- IT, Cloud, Software and Technology