Silicones vs. Traditional Adhesives: A Comparative Analysis in the Market

Introduction:

Silicone adhesives have become an integral part of numerous industries due to their exceptional properties and versatile applications. These adhesives, based on silicone polymers, offer unique advantages such as high thermal stability, excellent chemical resistance, and superior flexibility. As a result, they have gained significant popularity in sectors ranging from automotive and electronics to construction and medical devices. This article explores the growing demand and applications of silicone adhesives in various industries, highlighting their benefits and future prospects.

Automotive Industry:

The automotive industry has witnessed a substantial increase in the use of silicone adhesives. These adhesives are widely employed in applications such as bonding gaskets, sealing components, and securing electronic modules. Silicone adhesives provide excellent adhesion to various substrates, including metals, plastics, and glass, while offering resistance to temperature extremes and automotive fluids. Additionally, they contribute to enhanced durability, noise reduction, and improved overall performance of automotive assemblies.

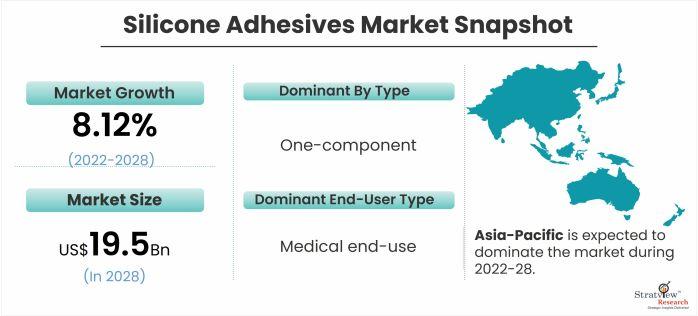

The silicone adhesives market was estimated at USD 2.17 Billion in 2021 and is likely to grow at a CAGR of 8.12% during 2022-2028 to reach USD 3.77 Billion in 2028.

Read more: https://www.stratviewresearch.com/595/silicone-adhesives-market.html

Electronics and Electrical Industry:

Silicone adhesives play a crucial role in the electronics and electrical industry. They are used for bonding and encapsulating sensitive electronic components, sealing connectors, and providing protection against moisture, dust, and vibrations. Silicone adhesives offer excellent electrical insulation properties, thermal conductivity, and resistance to UV radiation, making them suitable for applications that require reliable performance in challenging environments. With the rapid advancements in electronic devices and the increasing demand for miniaturization, silicone adhesives have become indispensable in ensuring product integrity and reliability.

Construction Industry:

In the construction industry, silicone adhesives are widely used for sealing and bonding applications. They are utilized for weatherproofing, sealing joints, adhering architectural panels, and bonding various construction materials. Silicone adhesives exhibit excellent adhesion to concrete, glass, metal, and other common building substrates. Moreover, their resistance to temperature fluctuations, ultraviolet (UV) rays, and weathering make them ideal for exterior applications, including curtain walls, window glazing, and expansion joint sealing.

Medical and Healthcare Industry:

Silicone adhesives have found extensive applications in the medical and healthcare sector. They are utilized in the assembly of medical devices, such as catheters, pacemakers, and wound care products. Silicone adhesives provide biocompatibility, flexibility, and sterility, making them suitable for direct skin contact and internal medical applications. They offer strong bonding capabilities, allowing for secure assembly of intricate medical components, while maintaining the necessary hygiene standards.

Future Prospects:

The demand for silicone adhesives is expected to witness significant growth in the coming years. As industries continue to prioritize advanced materials that meet stringent performance requirements, silicone adhesives are likely to emerge as a preferred choice. The development of specialized formulations, such as low-VOC (volatile organic compound) and UV-curable silicone adhesives, will further expand their application possibilities. Additionally, ongoing research in nanotechnology and hybrid adhesive systems holds promising potential for enhancing the performance characteristics of silicone adhesives and opening up new avenues of application.

Conclusion:

Silicone adhesives have become indispensable in various industries due to their exceptional properties and diverse applications. The automotive, electronics, construction, and medical sectors, among others, rely on these adhesives for bonding, sealing, and protection purposes. With their unique combination of properties, including high thermal stability, chemical resistance, and flexibility, silicone adhesives offer reliable solutions for demanding applications. As technology advances and new challenges arise, the demand for silicone adhesives is expected to continue growing, driving innovation and further expanding their application range across industries

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Games

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness

- IT, Cloud, Software and Technology