The Ride On Toy Manufacturing Process at Ying Hao Toys: Custom and Quality

The creation of a custom ride-on toy involves far more than simply molding plastic and adding wheels. At Ying Hao Toys, the manufacturing process represents a carefully orchestrated symphony of design innovation, engineering precision, and quality assurance that transforms concepts into cherished childhood companions. Their approach blends state-of-the-art technology with human craftsmanship, ensuring each vehicle meets rigorous safety standards while delivering the magical play experience children deserve. This meticulous process explains why brands worldwide trust Ying Hao with their most important product lines.

Initial Design Collaboration and Conceptualization

Every exceptional ride on toy manufacturer with a shared vision between client and manufacturer. Ying Hao's process starts with immersive design consultations where clients present their concepts, target age groups, and brand objectives. Their design team then translates these ideas into technical sketches and 3D models, considering aesthetics, functionality, and manufacturability from the earliest stages. This collaborative phase often involves multiple iterations as both parties refine proportions, features, and styling details. The result is a design that balances creative ambition with practical engineering, ensuring the final product will be both beautiful and durable enough for real-world use.

Engineering Analysis and Prototype Development

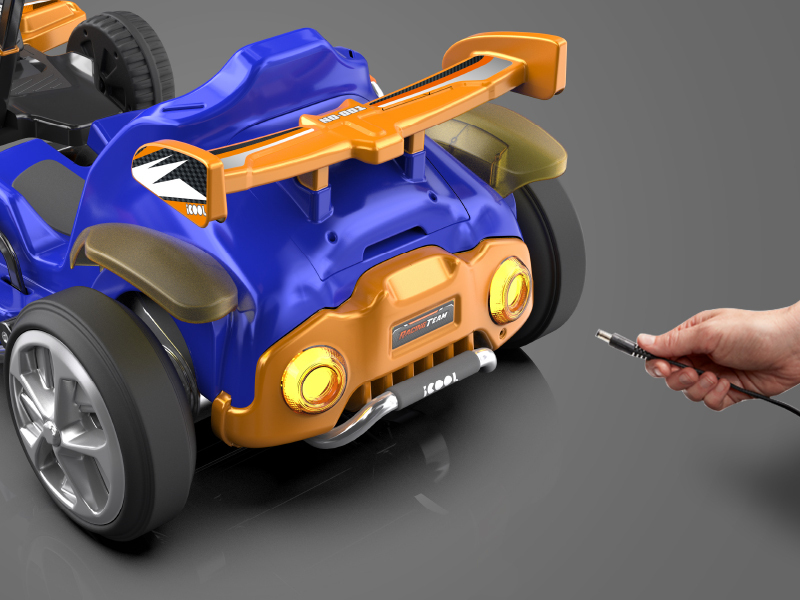

Once designs are finalized, Ying Hao's engineering team conducts comprehensive digital analysis using advanced simulation software. They assess structural integrity, weight distribution, stress points, and safety compliance before any physical parts are created. This virtual testing allows them to identify potential issues and make adjustments at minimal cost. Following digital approval, they produce functional prototypes using precision machining and 3D printing technologies. These prototypes undergo rigorous hands-on testing for stability, durability, and play value, providing tangible proof of concept before committing to expensive production tooling.

Precision Tooling and Mold Manufacturing

The transition from prototype to production begins with crafting precision molds that will form the toy's components. Ying Hao's tooling department manufactures custom molds using CNC machining and electrical discharge machining (EDM) processes that achieve tolerances within hundredths of a millimeter. These molds are crafted from premium hardened steel to withstand millions of cycles while maintaining precise dimensions. The tooling team incorporates sophisticated features like conformal cooling channels that ensure even temperature distribution during injection molding, resulting in consistent part quality and reduced production cycle times.

Injection Molding with Material Expertise

At the heart of the manufacturing process lies injection molding, where Ying Hao's expertise truly shines. They operate automated molding presses equipped with robotic part removal systems that ensure consistent quality across production runs. Their material scientists select engineering-grade plastics based on specific performance requirements—impact-resistant ABS for body parts, flexible PP for components requiring give, and durable polyethylene for structural elements. The molding process严格控制 temperature, pressure, and cycle times to produce parts with perfect surface finishes, consistent coloration, and dimensional stability part after part.

Quality-Focused Assembly Procedures

Assembly transforms individual components into complete vehicles through a series of carefully designed stations. Ying Hao's production lines balance automation with skilled manual assembly, using specialized jigs and fixtures that ensure perfect alignment of components. Workers receive detailed training on specific assembly processes, with quality checks integrated after each major step. Electrical systems undergo rigorous testing before installation, while mechanical components like axles and steering mechanisms are lubricated and adjusted to precise specifications. This methodical approach results in products that perform flawlessly right out of the box.

Comprehensive Testing and Quality Assurance

Before any product leaves the factory, it must pass Ying Hao's multi-layered quality assurance protocol. Their testing laboratory subjects random samples from each production run to tests that simulate years of use—stress tests on structural components, cycle tests on moving parts, and environmental tests exposing products to extreme temperatures and humidity. Electronic components undergo electrical safety testing and performance verification. Additionally, their quality team conducts thorough visual inspections, checking for perfect paint finishes, proper decal application, and overall aesthetic excellence. Only products meeting all specifications receive final approval for shipment.

Continuous Improvement and Client Collaboration

Even after production begins, Ying Hao maintains ongoing communication with clients to ensure complete satisfaction. They provide regular production updates and quality reports, and remain responsive to feedback throughout the manufacturing process. Their engineering team continuously analyzes production data to identify opportunities for refinement, whether through material improvements, process optimizations, or design enhancements. This commitment to continuous improvement means that clients benefit from evolving manufacturing excellence throughout their partnership, receiving products that represent the current pinnacle of what's possible in ride-on toy manufacturing.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Spiele

- Gardening

- Health

- Startseite

- Literature

- Music

- Networking

- Andere

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness

- IT, Cloud, Software and Technology