Overcoming Thermal Challenges in Power MOSFET Applications

Thermal management is a key challenge in power Metal-Oxide-Semiconductor Field-Effect Transistors (MOSFETs) applications, as excessive heat can degrade device performance, affect system reliability, and shorten the lifespan of power electronics systems. Effective thermal management strategies are crucial to ensure optimal operation and prevent thermal-related failures.

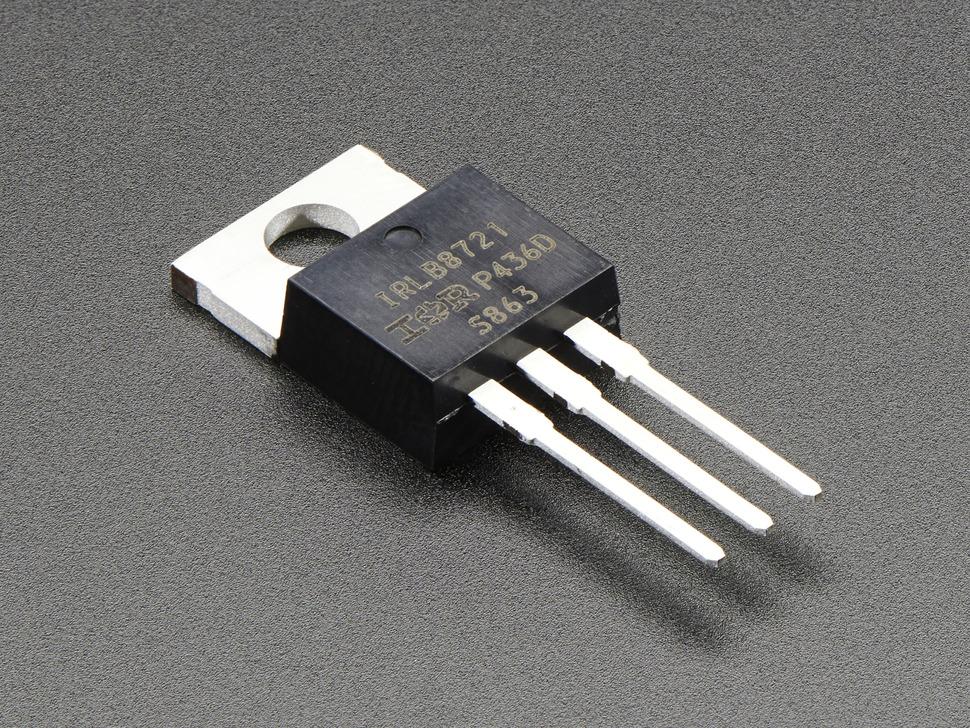

One approach to overcoming thermal challenges is selecting power MOSFETs with low thermal resistance. MOSFETs with optimized designs and advanced packaging technologies help dissipate heat efficiently, reducing temperature rise and minimizing thermal stress. Low on-resistance (Rds(on)) MOSFETs generate less heat during operation, resulting in lower power losses and reduced thermal load on the device.

Heat sinks and thermal interface materials (TIMs) are commonly used to enhance thermal dissipation in Power MOSFET applications. Heat sinks provide extended surface area for heat transfer, while TIMs improve thermal conductivity between the MOSFET and the heat sink. Proper selection and design of heat sinks and TIMs ensure effective heat dissipation and maintain the MOSFET's temperature within acceptable limits.

In applications with high power density and limited space, liquid cooling solutions offer effective thermal management for power MOSFETs. Liquid-cooled heat sinks or cold plates circulate a coolant, such as water or liquid refrigerant, to absorb and carry away heat from the MOSFET. Liquid cooling provides higher thermal conductivity compared to air cooling and enables efficient heat transfer, allowing power MOSFETs to operate at lower temperatures.

Thermal simulation and analysis tools play a crucial role in overcoming thermal challenges in power MOSFET applications. These tools allow engineers to predict and optimize heat dissipation by modeling the system, simulating thermal behavior, and identifying potential hotspots. Through iterative design and simulation, engineers can implement effective thermal management solutions and ensure safe operating temperatures for power MOSFETs.

Furthermore, innovative materials, such as wide bandgap semiconductors like silicon carbide (SiC) and gallium nitride (GaN), offer superior thermal properties compared to traditional silicon-based MOSFETs. These materials exhibit higher thermal conductivity, lower thermal resistance, and better heat dissipation capabilities, enabling power MOSFETs to operate at higher power densities and temperatures.

Overcoming thermal challenges is essential for optimizing the performance and reliability of power MOSFETs in various applications. Through careful selection of MOSFETs with low thermal resistance, effective heat sink designs, liquid cooling solutions, and thermal simulation tools, engineers can effectively manage heat dissipation, mitigate thermal stress, and ensure the long-term operation of power electronics systems.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Games

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness

- IT, Cloud, Software and Technology