Global Die Casting Market Is Estimated To Witness High Growth Owing To Increasing Industrial Applications and Technological Advancements

The global Die Casting Market is estimated to be valued at USD 77.99 billion in 2023 and is expected to exhibit a CAGR of 6.24% over the forecast period 2023-2028, as highlighted in a new report published by Coherent Market Insights.

A) Market Overview:

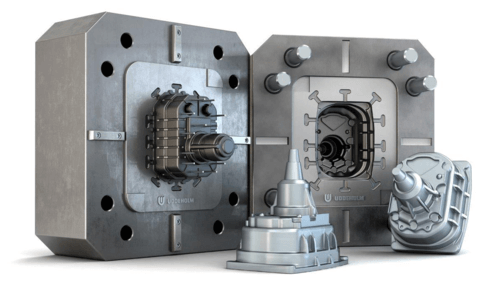

The Die Casting Market involves the manufacturing process of creating intricate metal parts by injecting molten metal into a die or mold. This process is widely used in various industries such as automotive, aerospace, electronics, and telecommunications, among others. Die casting offers a cost-effective solution for producing accurate and complex parts with high precision and dimensional stability.

B) Market Dynamics:

The two primary drivers contributing to the growth of the Die Casting Market include increasing industrial applications and technological advancements.

1. Increasing Industrial Applications: The Die Casting Market is experiencing significant demand due to the growing use of die-cast components in various industries. The automotive industry, in particular, is a major consumer of die-cast parts for manufacturing components such as engine blocks, transmission cases, and structural components. The aerospace industry also extensively uses die-cast parts for manufacturing lightweight components with high structural integrity. Furthermore, the electronic industry utilizes die-cast parts for housing connectors, switches, and other electronic components.

2. Technological Advancements: The Die Casting Market is constantly evolving due to technological advancements. The development of computer-aided design (CAD) software has revolutionized the design and production process of die-cast parts. CAD software allows manufacturers to create complex and accurate designs, which can be easily converted into molds for die casting. Additionally, advancements in alloy materials have led to the production of lightweight die-cast components with superior strength and heat resistance. These advancements have increased the efficiency and performance of die-cast parts, driving the growth of the market.

C) Segment Analysis:

The automotive segment dominates the Die Casting Market due to the high demand for die-cast components in the automotive industry. Die-cast parts are extensively used in engine components, transmission cases, and structural parts, among others. The ability of die-casting to produce lightweight and high-strength components makes it ideal for the automotive industry. Other segments such as aerospace, electronics, and telecommunications also contribute to the growth of the market.

C) PEST Analysis:

Political: The political stability and government policies in key manufacturing regions can impact the growth of the Die Casting Market. Changes in trade policies and tariffs can affect the import and export of die-cast components, influencing market dynamics.

Economic: The economic landscape and growth of end-use industries play a crucial role in the demand for die-cast components. Economic fluctuations can impact consumer spending, which can subsequently affect the demand for automobiles, aerospace equipment, and electronic devices, among others.

Social: The growing population and urbanization have led to an increased demand for automobiles and electronic devices. This, in turn, drives the demand for die-cast components, as they are essential for manufacturing these products.

Technological: Technological advancements such as CAD software and alloy materials have revolutionized the die-casting process, making it more efficient and precise. These advancements contribute to the growth of the Die Casting Market.

E) Key Takeaways:

- The global Die Casting Market is expected to witness high growth, exhibiting a CAGR of 6.24% over the forecast period, due to increasing industrial applications and technological advancements.

- Asia-Pacific is the fastest-growing and dominating region in the Die Casting Market, attributed to the rapid industrialization and increasing demand for automobiles and electronic devices.

- Key players operating in the global Die Casting Market include Alcast Technologies, Arconic, Consolidated Metco, Inc., Dynacast International Inc., Gibbs Die Casting, Ryobi Die Casting Inc., Bodine Aluminum, Martinrea Honsel Germany GmbH, Leggett & Platt, Endurance Technologies Ltd., Empire Die Casting Company, Alcoa Inc., Hitachi Metals Ltd, Nemak S.A.B. de C.V., GF Casting Solution AG, Shiloh Industries Inc., Rheinmetall Automotive AG, Sigma Electric Manufacturing Corp., Pace Industries, and Guangdong Yizumi.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Spellen

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness

- IT, Cloud, Software and Technology