The global Physical Vapor Deposition (PVD) market is estimated to be valued at US$ 18.9 billion in 2021 and is expected to exhibit a CAGR of 5.59% over the forecast period 2022-2030, as highlighted in a new report published by Coherent Market Insights.

A) Market Overview:

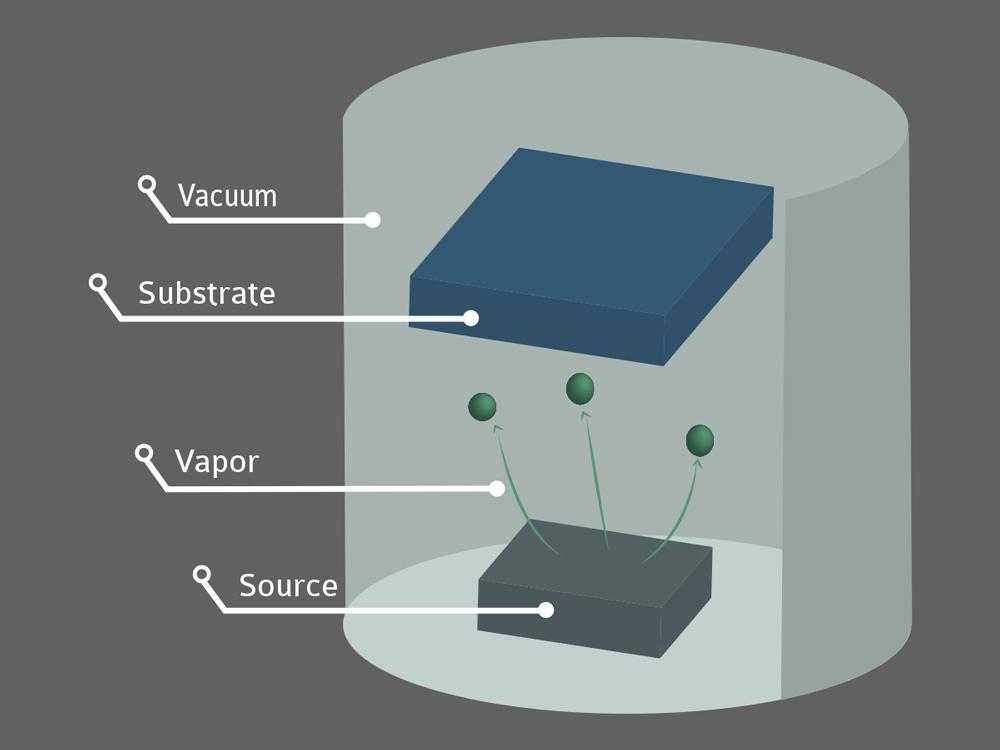

Physical Vapor Deposition (PVD) is a thin-film deposition technique that is widely used in various industries such as automotive, aerospace, electronics, medical, and packaging. The process involves the deposition of materials onto a substrate in a vacuum environment. PVD is known for its ability to provide high-quality and durable coatings with excellent adhesion properties. It offers various advantages such as enhanced wear resistance, high corrosion protection, improved hardness, and low friction coefficient. PVD coatings find applications in a wide range of products, including cutting tools, decorative coatings, solar panels, and semiconductors, among others.

B) Market Dynamics:

1) Increasing Demand for Advanced Coating Solutions:

The growing demand for high-performance and durable coatings is one of the major drivers for the PVD market. Industries such as automotive and aerospace require advanced coatings to enhance the durability, aesthetics, and functionality of their products. PVD coatings offer excellent adhesion, wear resistance, and corrosion protection, making them ideal for use in these industries. The rising need for lightweight and fuel-efficient vehicles is also contributing to the demand for PVD coatings, as they can help reduce friction and improve fuel efficiency.

For instance, the automotive industry is increasingly using PVD coatings for engine components, pistons, and gears to reduce friction, decrease wear and tear, and improve overall performance. Similarly, the aerospace industry is utilizing PVD coatings for turbine blades, landing gears, and other critical components to enhance their corrosion resistance and lifespan.

2) Technological Advancements:

Advancements in PVD technology are driving market growth. Manufacturers are continuously investing in research and development activities to improve the efficiency and performance of PVD coatings. The development of new coating materials, such as diamond-like carbon (DLC), is opening up new opportunities for the PVD market. DLC coatings offer excellent hardness, low friction, and high wear resistance, making them suitable for various applications, including cutting tools, medical devices, and optical coatings.

Additionally, the integration of PVD with other technologies, such as plasma ion-assisted deposition (PIAD) and magnetron sputtering, is further enhancing the capabilities and versatility of PVD coatings.

C) SWOT Analysis:

Strengths:

1) High-quality and durable coatings

2) Wide range of applications

Weaknesses:

1) High initial setup costs

2) Limited coating thickness

Opportunities:

1) Growing demand for PVD coatings in emerging economies

2) Increasing adoption of PVD coatings in the healthcare sector

Threats:

1) Intense competition from alternative coating technologies

2) Volatility in raw material prices

D) Key Takeaways:

- The Global Physical Vapor Deposition Market Demand is expected to witness high growth, exhibiting a CAGR of 5.59% over the forecast period, due to increasing demand for advanced coating solutions in various industries.

- North America is expected to dominate the PVD market, followed by Europe and Asia Pacific, due to the presence of key players and a strong manufacturing base in these regions.

- Key players operating in the global Physical Vapor Deposition market include Oerlikon Balzers (Oerlikon Group), IHI Corporation, Silfex Inc., Lam Research Corp, Singulus Technologies AG, Applied Materials, Inc., ULVAC Inc., Veeco Instruments Inc., Buhler AG, Semicore Equipment, Inc., and Platit AG. These companies are focusing on strategic partnerships, acquisitions, and product launches to expand their market share and enhance their product portfolio.

In conclusion, the Physical Vapor Deposition market is expected to grow significantly in the coming years, driven by the increasing demand for advanced coating solutions and continuous technological advancements. The market offers lucrative opportunities for manufacturers, especially in emerging economies and the healthcare sector. However, players need to overcome challenges such as high initial setup costs and competition from alternative coating technologies to maintain their market position.

Global Physical Vapor Deposition Market is Estimated to Witness High Growth