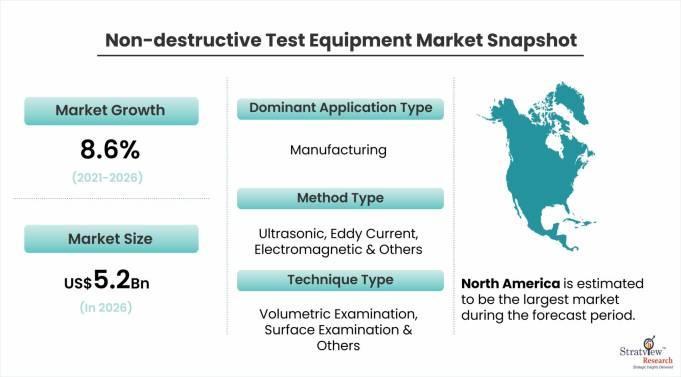

The Non-destructive Test Equipment Market is segmented by Method (Ultrasonic, Eddy Current, Electromagnetic, Radiography, Thermography, Other), Technique (Volumetric Examination, Surface Examination, Others), Application (Manufacturing, Petrochemical, Aerospace, Automotive, Power Generation, Others), and Region (North America, Europe, Asia-Pacific, and the Rest of the World).

Ensuring Quality and Safety: Role of Non-Destructive Testing Equipment

In industries where structural integrity, product quality, and safety are paramount, non-destructive testing (NDT) equipment plays a pivotal role. NDT methods are instrumental in assessing the integrity of materials, components, and structures without causing damage, making them essential for maintaining high standards and ensuring safety across various sectors.

Quality Assurance: NDT equipment is the guardian of quality assurance in manufacturing and construction. It allows professionals to identify defects, inconsistencies, or flaws in materials and products, ensuring that only items meeting stringent standards reach the market.

Safety Assessment: NDT equipment is critical for assessing the safety of critical infrastructure, such as bridges, pipelines, and nuclear facilities. By detecting hidden flaws and weaknesses, NDT ensures that these structures remain safe for public use and operation.

Aerospace and Automotive: In the aerospace and automotive industries, NDT equipment is indispensable for inspecting aircraft components, engines, and vehicle parts. It aids in preventing catastrophic failures by identifying fatigue cracks or material degradation.

Oil and Gas Exploration: NDT equipment plays a vital role in the oil and gas sector, ensuring the integrity of pipelines and equipment. It helps detect corrosion, erosion, or defects that could lead to leaks or accidents.

Advancements: Innovations in NDT equipment, such as advanced sensors, robotics, and digital imaging, have expanded its capabilities. These technologies enhance the accuracy, efficiency, and scope of NDT, further improving safety and quality standards.

In conclusion, NDT equipment is the silent guardian that upholds quality and safety across a wide range of industries. Its ability to assess materials and structures without causing harm is a testament to its crucial role in ensuring the reliability and safety of the products and infrastructure we rely on daily.