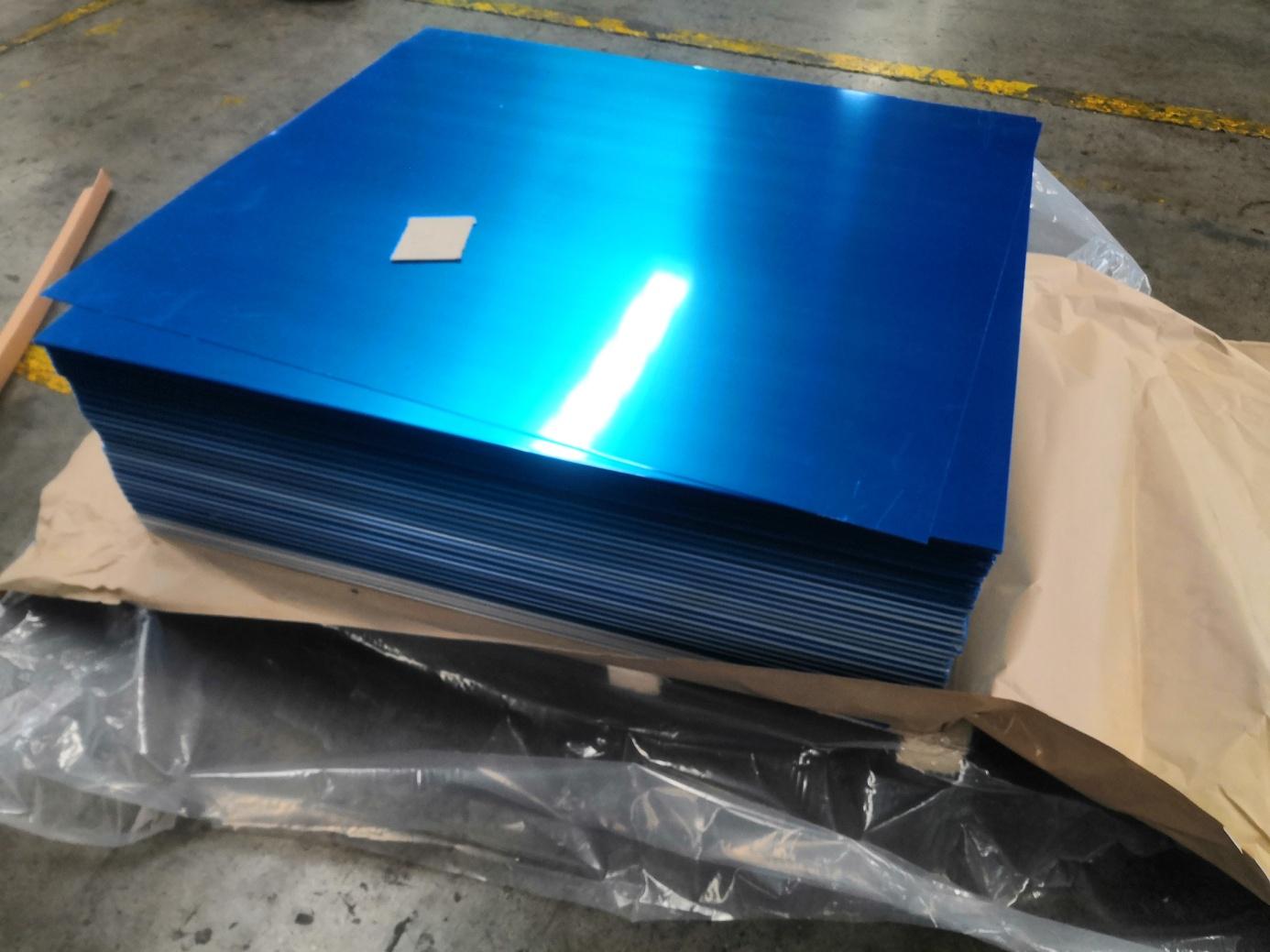

Alloy Sheet metallic

Anti-rust alloy sheet metallic mainly consists of aluminum-magnesium alloy and aluminum-manganese alloy, due to the fact the alloy additives among the 2 growth their anti-corrosion overall performance. Such sheet metal alloys can not be reinforced through warmness treatment, so their energy is low. The principle performance feature of this sort of aluminum sheet alloy is its high-quality corrosion resistance, so it is called anti-rust aluminum.Anti-rust aluminum alloy sheet metalis generally used in the annealed or cold paintings hardened kingdom. It has high plasticity, low power, brilliant corrosion resistance and welding performance, clean to technique and shape, and has excellent gloss and coffee temperature overall performance. It's far appropriate for production in corrosive environments. It is the maximum widely used aluminum alloy in welded structures for parts that aren't concern to much pressure.

The rust-proof aluminum sheet that can't be warmness handled and bolstered is specifically advanced in strength and hardness by work hardening. After paintings hardening, distinct annealing temperatures are used to achieve the specified strength and plasticity to meet special application necessities.The representatives of aluminum-manganese aluminum sheet alloys are 3105, 3004, 3003 aluminum alloys, the first form of wire and other high conductivity requirements are used above. The second one kind is typically used on cans, and the ultimate type is widely used, including kitchen utensils, meals and chemical merchandise processing and garage devices, tanks and tanks for transporting liquid merchandise, and diverse pressure vessels and pipes made of thin plates.In step with the extent of magnesium content material, aluminum-magnesium alloy sheet steel are: 5005 5252 5251 5050 5052 aluminum alloy, and so on., which are respectively used in some industries with high anti-corrosion overall performance and excessive power requirements, such as shipbuilding, containers and subway high-speed trains. Within the ecosystem, water pressure-achievable aluminum alloy with right corrosion resistance in media which include oil and oil.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Games

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness

- IT, Cloud, Software and Technology