Global Physical Vapor Deposition Market Is Estimated To Witness High Growth Owing To Increasing Demand from Electronics

The Global Physical Vapor Deposition (PVD) Market is estimated to be valued at US$ 18.9 Billion in 2021 and is expected to exhibit a CAGR of 5.59% over the forecast period 2022-2030, as highlighted in a new report published by Coherent Market Insights.

Market Overview:

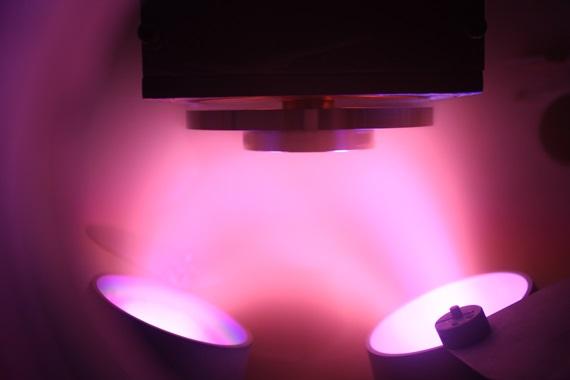

Physical Vapor Deposition (PVD) is a vacuum coating process used to produce thin films and coatings. It finds extensive applications in various industries such as electronics, automotive, aerospace, medical, and others. PVD coatings are widely used for enhancing the durability, corrosion resistance, and aesthetic appeal of products. The increasing demand for PVD coatings from the electronics and automotive industries is expected to drive market growth. PVD coatings are extensively used in the production of microchips, circuit boards, sensors, and automotive parts such as engine components and decorative trims.

Market Dynamics:

The growth of the PVD market is primarily driven by two major factors. Firstly, the increasing demand for electronic devices, including smartphones, tablets, and wearables, is fueling the demand for PVD coatings. These coatings provide protection against corrosion and wear, thereby increasing the lifespan of electronic components. Secondly, the automotive industry is witnessing a surge in the adoption of PVD coatings for various applications such as engine components, exterior trims, and decorative parts. PVD coatings offer enhanced durability, scratch resistance, and aesthetic appeal to automotive components. The growing automotive industry, coupled with the increasing focus on vehicle aesthetics, is expected to drive market growth.

SWOT Analysis:

Strengths:

- Physical vapor deposition market is experiencing significant growth due to the increasing demand from various end-use industries such as electronics, automotive, and healthcare.

- PVD technology offers advantages like improved adhesion, uniformity, and durability of coatings, driving its adoption in different applications.

- The market is witnessing continuous innovations in PVD equipment and materials, enhancing the overall efficiency and performance.

Weaknesses:

- High initial investment and maintenance cost associated with PVD equipment pose a challenge for small-scale manufacturers, limiting their adoption.

- PVD process has certain limitations in terms of coating thickness and substrate material compatibility, which may restrict its application in some industries.

Opportunities:

- Rapid technological advancements in PVD techniques, such as magnetron sputtering and arc evaporation, create opportunities for improved coating quality and efficiency.

- Growing focus on eco-friendly and sustainable coatings is driving the demand for PVD processes as they offer environmentally friendly alternatives to traditional coating methods.

Threats:

- Intense competition from alternative coating methods like chemical vapor deposition (CVD) and electroplating may pose a threat to the growth of the physical vapor deposition market.

- Economic slowdown and fluctuations in raw material prices can have a negative impact on the market, leading to a decrease in demand.

Key Takeaways:

The global Physical Vapor Deposition Market Analysis is expected to witness high growth, exhibiting a CAGR of 5.59% over the forecast period (2022-2030), due to increasing demand from various end-use industries. North America is expected to be the fastest-growing and dominating region in the market, driven by the presence of major manufacturers and increasing investments in advanced technologies. Key players operating in the physical vapor deposition market include Oerlikon Balzers, IHI Corporation, Silfex Inc., Lam Research Corp, Singulus Technologies AG, Applied Materials, Inc., ULVAC Inc., Veeco Instruments Inc., Buhler AG, Semicore Equipment, Inc., and Platit AG. These companies are focusing on product innovations, strategic collaborations, and mergers & acquisitions to strengthen their market position.

Read more @ https://creativeedge16.blogspot.com/2023/10/physical-vapor-deposition-market-is.html

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Spellen

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness

- IT, Cloud, Software and Technology