Carbon Capture and Storage in Industry: Solutions for Emissions Reduction

Introduction

In the battle against climate change, the industrial sector stands as a significant contributor to global greenhouse gas emissions. Finding effective solutions to reduce emissions from industries like manufacturing, cement production, and chemical processing is paramount. One promising technology at the forefront of this effort is Carbon Capture and Storage (CCS). In this article, we will explore how CCS is being implemented in various industrial processes, its benefits, and its potential to revolutionize emissions reduction in the industrial sector.

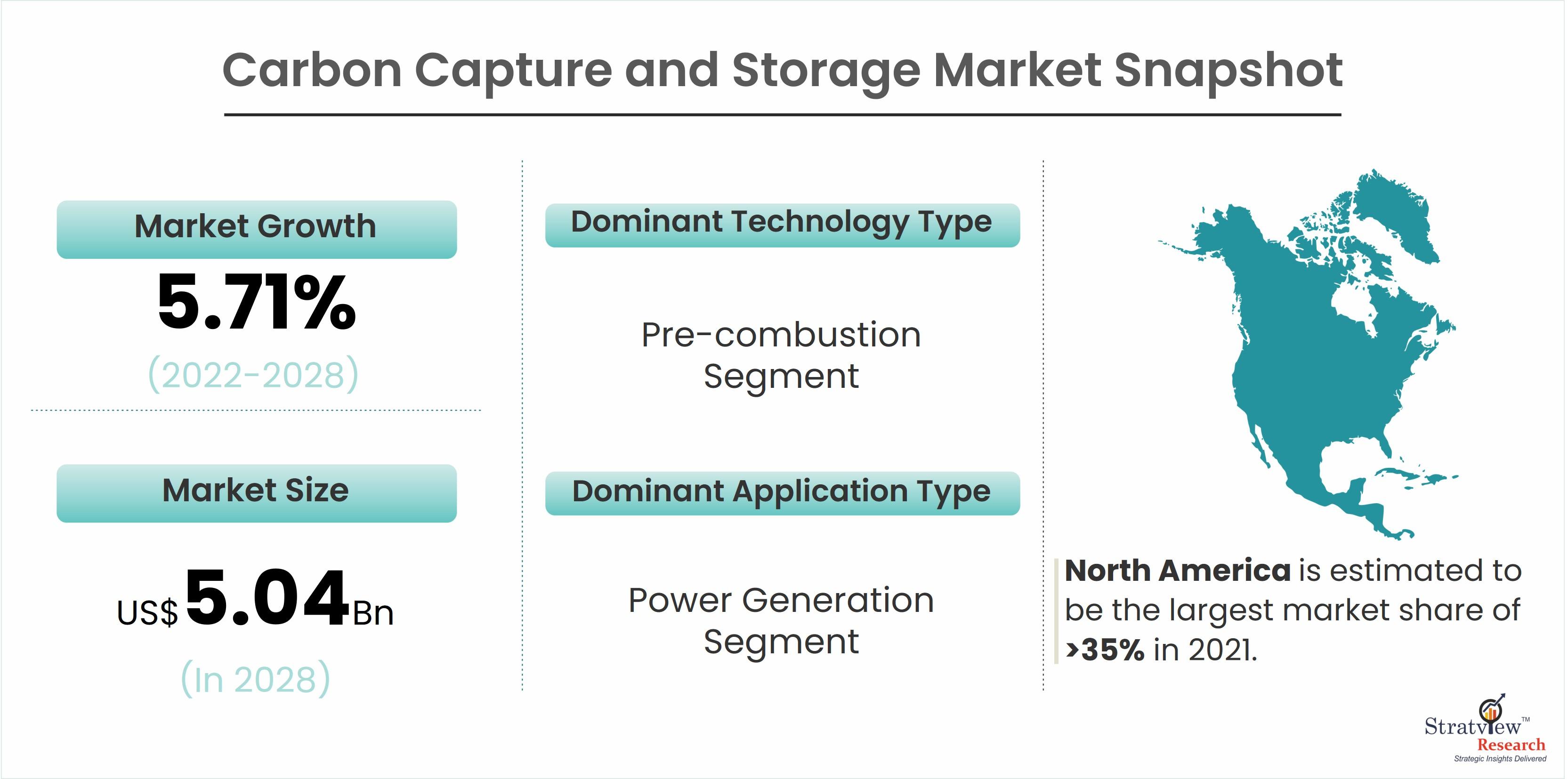

As per the study, The Global Carbon Capture and Storage Market is expected to reach an estimated value of US$ 5.04 Billion by 2028 from US$ 3.38 Billion in 2021 and is likely to grow at a CAGR of 5.71% during the forecast of 2022-2028.

Carbon capture and storage is the processing of capturing waste carbon dioxide, transporting it to a storage site, and depositing it where it will not enter the atmosphere. The market is segmented by technology type into pre-combustion, post-combustion, and oxyfuel combustion and by application type into oil & gas, chemical processing, power generation, and others.

To learn more about the report, click here:

https://www.stratviewresearch.com/1750/carbon-capture-and-storage-market.html

The Industrial Sector's Carbon Conundrum

The industrial sector is responsible for a substantial portion of global CO2 emissions, primarily due to energy-intensive processes and the use of fossil fuels. Processes like cement production, steelmaking, and chemical manufacturing release significant amounts of CO2 into the atmosphere.

Implementing CCS in Industrial Processes

Cement Production

Cement production is a major contributor to industrial emissions. The process involves heating limestone (calcium carbonate) to produce lime (calcium oxide), releasing CO2 in the process. Implementing CCS in cement plants involves capturing CO2 during the production process and then storing it underground.

Steelmaking

In the steelmaking process, CO2 is released from the chemical reactions that occur when iron ore is converted into iron and then further refined into steel. CCS can be applied in steel plants by capturing CO2 emissions from the blast furnace and other high-temperature processes.

Chemical Processing

Chemical processing facilities often emit CO2 during the production of various chemicals and plastics. CCS can be integrated into these processes to capture and store the CO2 before it is released into the atmosphere.

Refining and Petrochemicals

Oil refineries and petrochemical plants are significant emitters of CO2. CCS can be employed to capture emissions from various stages of the refining and chemical production processes.

Benefits of Implementing CCS in the Industry

Emissions Reduction

The primary benefit of implementing CCS in industrial processes is the substantial reduction of CO2 emissions. By capturing and storing CO2 at the source, industries can significantly contribute to global efforts to combat climate change.

Maintaining Industrial Competitiveness

In industries heavily reliant on fossil fuels, such as steel and cement production, implementing CCS can help companies meet emissions targets and remain competitive in a rapidly changing regulatory landscape.

Demonstrating Environmental Leadership

By adopting CCS, industries can showcase their commitment to sustainability and environmental responsibility, which can be a valuable asset in attracting environmentally conscious customers and investors.

Challenges and Considerations

Technological Maturity

While CCS technologies have made significant advancements, there is room for further innovation to improve capture efficiency and reduce costs, particularly in the context of industrial applications.

Cost Considerations

The initial capital costs of implementing CCS in industrial processes can be substantial. However, as technology advances and economies of scale are realized, these costs are expected to decrease.

Regulatory and Policy Support

Government policies and incentives play a crucial role in incentivizing industries to adopt CCS. Robust regulatory frameworks and financial incentives can help offset the initial investment and create a supportive environment for CCS deployment.

Case Studies: Successful CCS Implementation in Industry

Boundary Dam, Canada

The Boundary Dam Power Station in Saskatchewan, Canada, is home to one of the world's first commercial-scale CCS projects at a coal-fired power plant. The project has been instrumental in demonstrating the feasibility of CCS in the power generation sector.

Norcem Brevik, Norway

The Norcem cement plant in Brevik, Norway, is a pioneering example of CCS implementation in cement production. It captures up to 400,000 tons of CO2 annually, making it a significant contributor to emissions reduction efforts.

Conclusion

Carbon Capture and Storage in industrial processes presents a powerful solution for emissions reduction in sectors traditionally associated with high emissions. By capturing CO2 at its source and safely storing it underground, industries can play a crucial role in the global effort to combat climate change. With continued technological advancements, supportive policies, and industry leadership, CCS holds the potential to revolutionize emissions reduction in the industrial sector, paving the way for a more sustainable and resilient future.

About Us

Stratview Research is a global market research firm, offering syndicated and custom research reports along with growth consulting services. Our business intelligence and industry research reports offer clients insightful market data to aid strategic decision-making. These exclusive reports are the result of exclusive research methodology and are available for key industries such as chemicals, composites, advanced materials, technology, renewable energy, and more.

Stratview Research delivers custom research services across sectors. In case of any custom research requirements, please send your inquiry to sales@stratviewresearch.com or connect with our experts at +1-313-307-4176.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Games

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness

- IT, Cloud, Software and Technology