What Is The Accuracy Of Web Guide System

High accurate web guiding system will help greatly improve productivity and reduce production waste. As a web guide system manufacturer, the question you will be asked commonly is that what is the accuracy of your web guiding? The answer always will be doubted, because the definition of the accuracy of the web guide system varies for different people. Before learning the accuracy of the web guiding system, there’s a simple question that why the web guide system is required?

Why web guide system Is required?

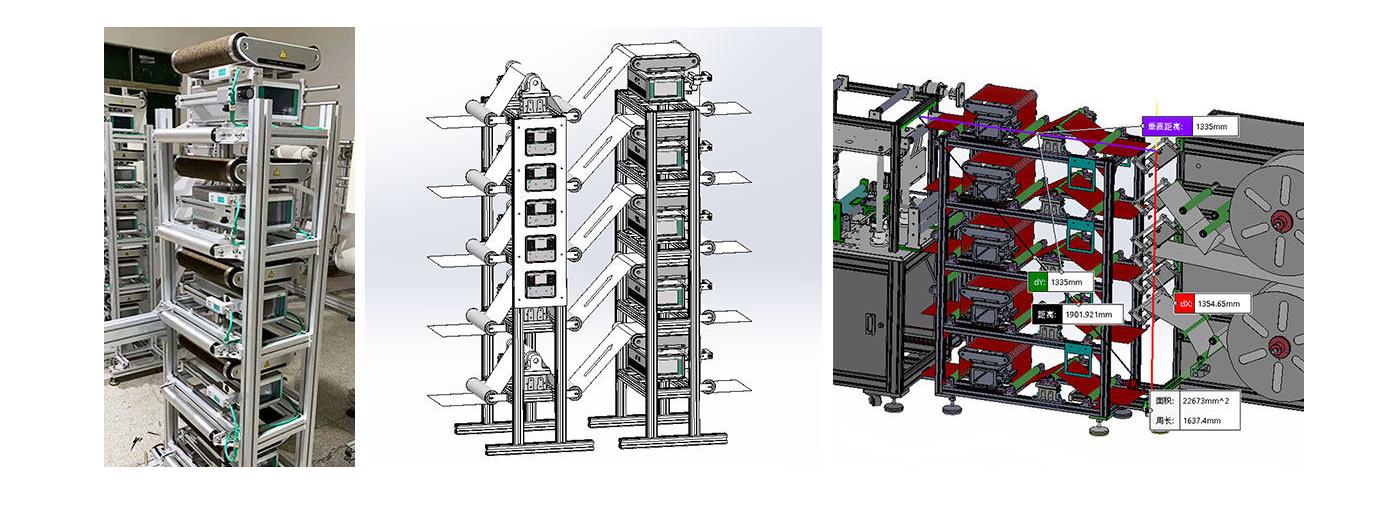

The edges or center lines of the process of coating, printing, compounding, dividing, and winding, otherwise, the transverse dislocation of the coil will cause the waste or even downtime. This is why the web guide system is required. It is the technique which will always coil side is neat and consistent. Usually, the tracking method of the web guide includes three types of edge, center and line.

What determines the accuracy of web guide system

The accuracy of the web guide is determined by three factors: the deviation of the invasive web, the accuracy of the web guide system, the installation accuracy of the system. Further, the unique features of the coiling are that the deviation of the invasive web, the lateral movement or swing size of the coil, which are important factors in determining the accuracy of the web guide.

The definition of the accuracy of web guide system

The web guide machine is typically upstream of a critical process, and the closer the process is, thus the maximum reduction in position deviation errors when entering the critical process. As a manufacturer of web guiding, need to follow the edge, center, or line position of the coil just from the probe. So it is recommended that installing the machine in the location closest to the key process.

For more professional knowledge, please visit the article page of The accuracy of web guide system.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Games

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness

- IT, Cloud, Software and Technology