Industrial Burner Market Is Estimated To Witness High Growth Owing To Increasing Demand For Green Technology

The Industrial Burner Market is estimated to be valued at US$ 11291.33 Mn in 2023 and is expected to exhibit a CAGR of 3.3% over the forecast period 2023 to 2030, as highlighted in a new report published by Coherent Market Insights.

Market Overview:

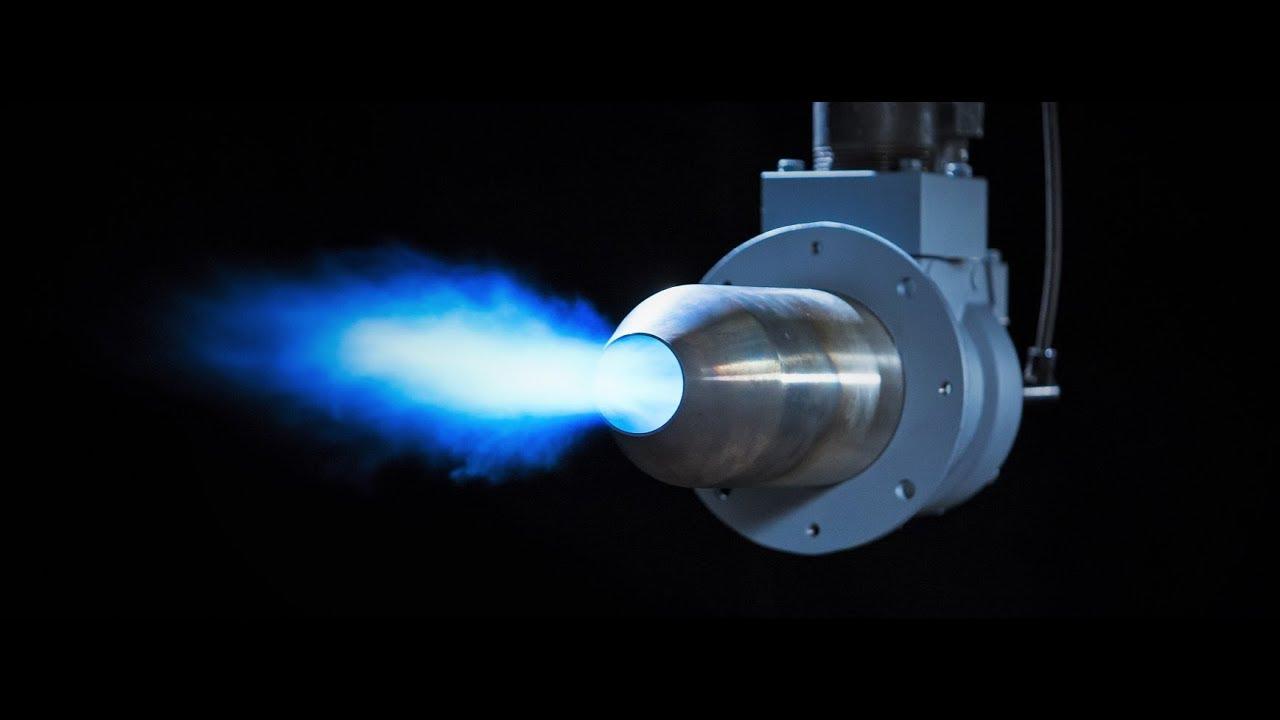

Industrial burners are combustion devices used in several industries such as oil & gas, chemical and petrochemical, power generation, food processing, etc. to generate heat through combustion of fossil fuels. They provide flame and heat for processes such as drying, baking, heating, sterilizing, and melting. Industrial burners offer advantages such as improved combustion efficiency, low emissions, compact design, and easy ignition. With growing industries worldwide, the demand for industrial burners is expanding rapidly.

Market key trends:

One of the major trends in the industrial burner market is the increasing demand for green technology. Stringent government regulations regarding pollution control are encouraging industries to adopt low NOx burners and ultra-low NOx burners that can reduce nitrogen oxide emissions significantly. Also, with growing emphasis on energy efficiency and sustainability, manufacturers are developing intelligent burner management systems and hybrid burners that can switch between different fuel types. Advanced combustion control techniques are also being used to optimize fuel and air mixture for maximum efficiency and minimum emissions.

Porter’s Analysis

Threat of new entrants: The threat of new entrants in the industrial burner market is moderate. Start-up costs and stringent government regulations regarding emissions acts as a barrier for new players.

Bargaining power of buyers: The bargaining power of buyers in the industrial burner market is moderate. Buyers can negotiate on price and demand customized solutions.

Bargaining power of suppliers: The bargaining power of suppliers is moderate. Availability of substitutes keeps supplier power in check. However, switching costs limit influence over prices.

Threat of new substitutes: Threat from substitutes is low as burners have applications across industries like oil & gas, chemical, food etc and alternatives do not provide the same operational efficiencies.

Competitive rivalry: The competitive rivalry in the market is high due to presence of large number of global and regional players providing differentiated products.

SWOT Analysis

Strength: The industrial burner market enjoys consistent demand owing to pervasive use across industries. Product innovations facilitate operational efficiency and fuel flexibility.

Weakness: Cost pressures arising from raw material price volatility and need for skilled workforce pose challenges. Compliance to evolving emission norms requires huge capital investments.

Opportunity: Growth avenues exist in modular, IoT integrated products catering to specific applications. Emerging economies offer scope due to infrastructure development.

Threats: Stringent regulations globally and fluctuations in crude oil prices impact projects and maintenance spends of end-users. Trade wars and geopolitical issues affect supply chain.

Key Takeaways

The Global Industrial Burner Market Size is expected to witness high growth, exhibiting CAGR of 3.3% over the forecast period, due to increasing demand for energy-efficient burners. Regions with large process industries like oil & gas, petrochemical, metals, mining constitute over 60% of total market.

Regional analysis

Asia Pacific dominates currently with a share of over 35% due to rapid industrialization in China and India. The region is expected to continue its dominance, growing at the fastest CAGR during the forecast period due to increasing number of plant expansions and new projects. Europe and North America constitute over 45% share collectively with stringent emission norms driving replacement demand.

Key players

Key players operating in the industrial burner market are ANDRITZ Group, Baltur S.p.A, Bloom Engineering, Wood Group PLC (Foster Wheeler AG), Honeywell International Inc. (Maxon), Limpsfield Combustion Engineering Ltd, Mitsubishi Hitachi Power Systems, Ltd (MHPS), Oilon Group, Osaka Gas Co., Ltd, Selas Heat Technology Company, R.W. Beckett Corp, SAACKE GmbH, Industrial Combustion IC, Wesman Group, Striko Westofen, Forbes Marshall Pvt. Ltd., QED Combustion, Alzeta Corporation, Alfa Therm Limited, Weishaupt, Enertech GmbH, Power Flame (Astec), EOGB Energy Products Ltd., Babcock Wanson, Riello S.p.A, Zeeco, Inc., Alfa Laval, Corbett Industries, Inc., Faber Burner Company, AGF Burner Inc., John Zink Hamworthy Combustion, Oxilon Private Limited, Wayne Combustion Systems, SECO/WARWICK, INC., Surface Combustion, Inc., Midco International, Inc., and ELCO GmbH.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Jogos

- Gardening

- Health

- Início

- Literature

- Music

- Networking

- Outro

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness

- IT, Cloud, Software and Technology