SCADA Market Analysis by Trends, Size, Share, Growth Opportunities, and Emerging Technologies

SCADA is a type of software application utilized for monitoring and controlling industrial procedures, it collects real-time data from remote locations to control industrial equipment. SCADA offers businesses the tools required to make and install data-driven decisions about their industrial procedures.

SCADA systems comprise numerous software and hardware mechanisms. SCADA hardware collects and provides data into field controller systems, which send the data to other systems that timely process and present it to HMI. Whereas, SCADA software examines and interprets the data which is then forwarded to the operators.

However, among these two mechanisms, the hardware mechanisms are larges used because of the high requirement for components such as PLC, RTU, and HMI in automation solutions and industrial processes to accomplish scalability, growth, and efficiency in the manufacturing sector.

Components of SCADA

SCADA systems comprise components utilized in the field to collect data in real-time, along with related systems to allow the collection of data and improve industrial automation. Some of the major components of SCADA are:

Human-machine Interface (HMI)

HMI is a user interface, that is an integration of software and hardware that allows easy communication between machines and humans. The key purpose of utilizing HMI is to enable the monitoring and controlling of industrial procedures from remote places, by eliminating the need for physical presence at that location.

Get More Insights: SCADA Market Revenue Estimation and Growth Forecast Report

Remote Terminal Units (RTU)

RTU are the most used components of SCADA systems. The main purpose of remote terminal units present at the remote location of the SCADA system is to forward all the gathered information and data to the central station through monitors, sensors, production processes, and others so that the data or information can be stored and supervised.

Communication System

SCADA communication can occur in various ways, and it is a main component of a monitoring system. Traditional SCADA communication happens through a modem, dedicated serial lines, or radio. But, nowadays, SCADA communications commonly occur through SONET or LAN. The communication process via a SCADA system includes various components of the SCADA system.

Who Uses SCADA?

SCADA systems are utilized by various industries to maintain and control effectiveness, communicate system problems to lessen downtime, and provide data for better decisions. SCADA systems are used in various modern industries, such as electrical power, water & wastewater, oil & gas, manufacturing, telecommunication, automotive, chemicals, pharmaceuticals, and food & beverages.

Among these, the automotive sector is the largest user of SCADA systems. This is because of the increasing requirement for real-time data to control and monitor equipment and manufacturing procedures, along with the surging implementation of SCADA solutions in automotive manufacturing and procedure facilities to enhance productivity & efficiency and lessen the human workload.

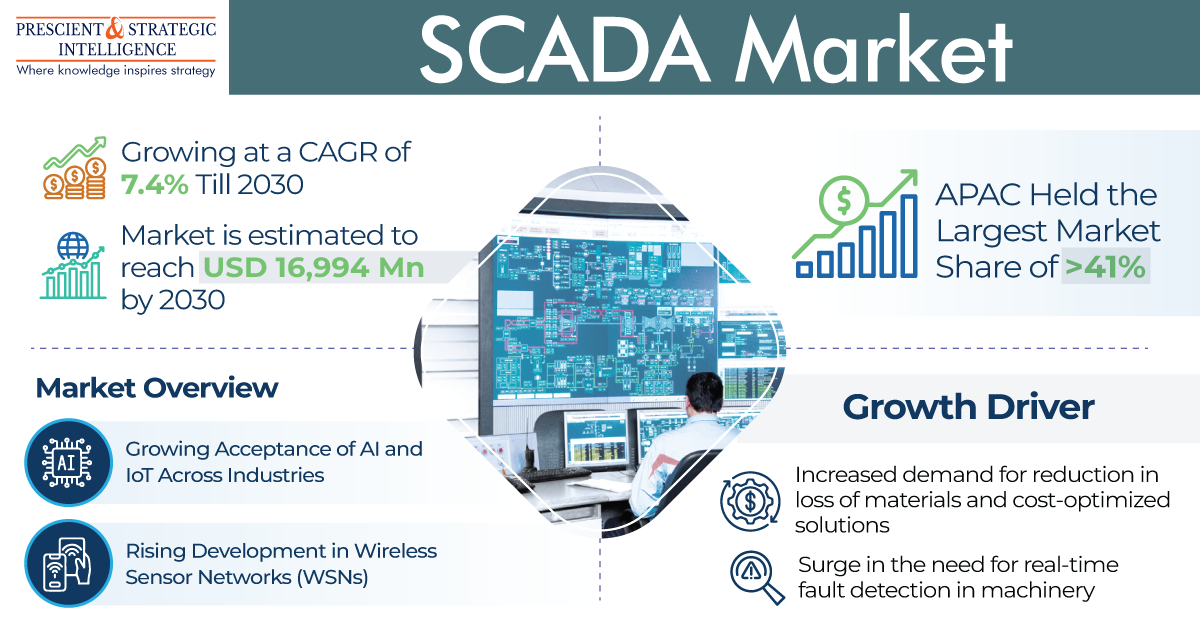

With the growing need for real-time machinery fault detection, the surging requirement for lesser materials lost and cost-effective solutions, and the mounting utilization of SCADA across Asia, its demand will reach a value of USD 16,994 million by the end of this decade.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Juegos

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness

- IT, Cloud, Software and Technology