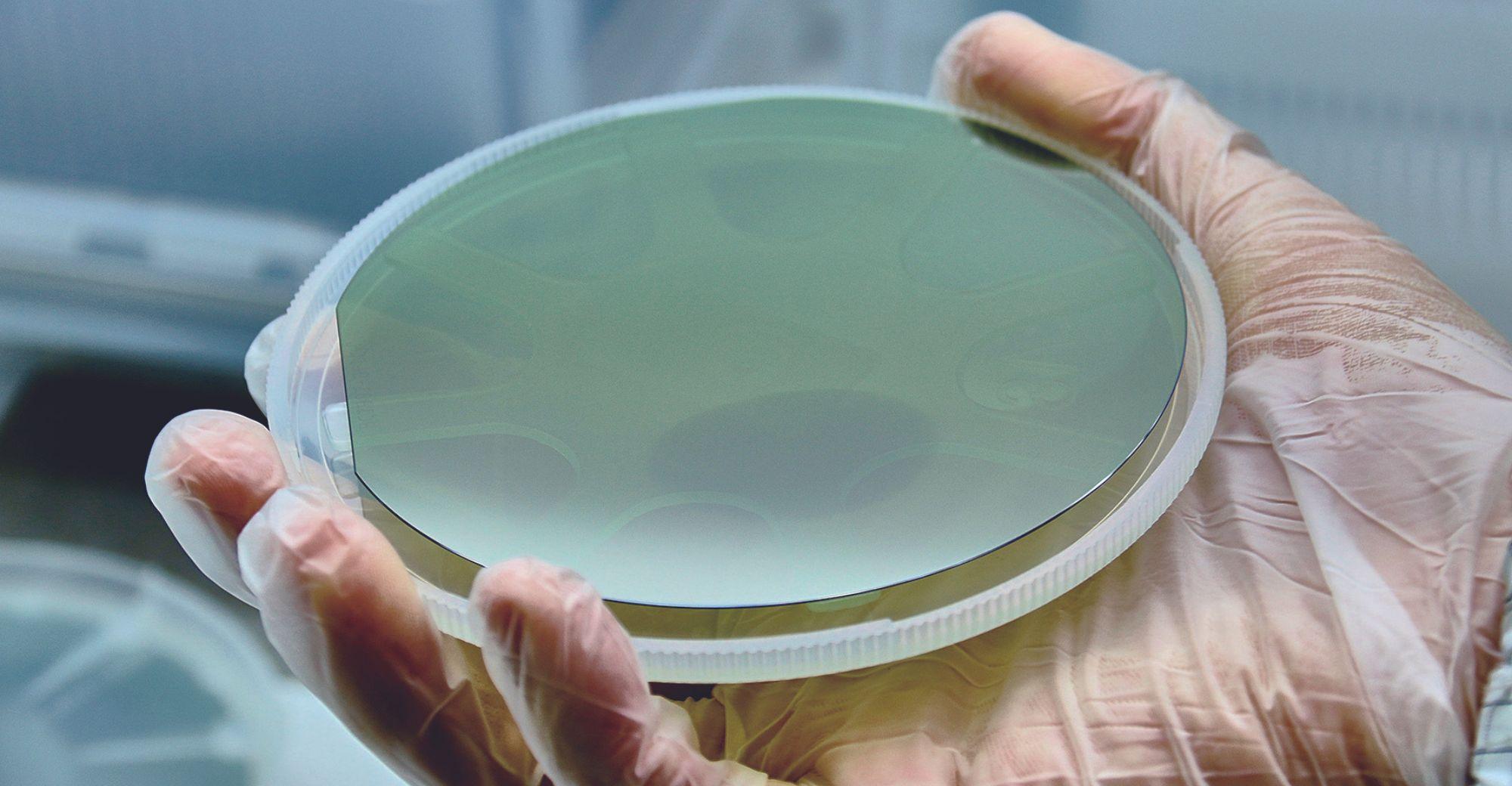

Epitaxial Wafer Is Estimated To Witness High Growth Owing To Rising Demand For Silicon-Based Power Electronics

The epitaxial wafer refers to manufacturing method that involves depositing a thin layer of a semiconductor material on a crystalline substrate or wafer in succession. It is widely used in power electronic devices, advanced LEDs, solar cells and semiconductor devices. The process is used to grow epitaxial layers like silicon, gallium arsenide or gallium nitride on a wafer substrate. These epitaxial layers are used as active layers in the fabrication of semiconductor devices and exhibit material properties and crystallographic orientations tailored to the specific device requirements. The global epitaxial wafer market is estimated to be valued at US$ 938.32 Bn in 2023 and is expected to exhibit a CAGR of 4.8% over the forecast period 2023 to 2030, as highlighted in a new report published by Coherent Market Insights.

Market Dynamics:

The demand for epitaxial wafers is primarily driven by rising adoption of silicon-based power electronics owing to their increasing usage in electric vehicles, fast charging infrastructure and renewable energy applications. Silicon-based power semiconductors have high-power handling capability and are cost-effective. Epitaxial wafers are used to grow ultrapure epitaxial silicon layers that act as the active region in power devices. Additionally, the growth in SiC and GaN power electronics is further fueling the demand for epitaxial wafer. SiC and GaN offer higher efficiency and power density compared to silicon. Growing electric vehicle production and demand for fast charging stations is expected to boost the epitaxial wafer market over the forecast period.

SWOT Analysis

Strength: The epitaxial wafer market has strong growth potential due to increasing demand for optoelectronics and photovoltaic devices. The epitaxial wafer allows high performance and low power consumption for applications in smartphones, wearables, and consumer electronics. It provides superior crystalline quality and thickness uniformity compared to conventional substrates.

Weakness: High material and manufacturing costs associated with epitaxial wafer production pose challenges in terms of profitability. Maintaining uniform film thickness and defect control over large substrate sizes requires advanced manufacturing capabilities.

Opportunity: Growing adoption of LED lighting and display technology as well as increasing commercialization of autonomous vehicles create opportunities for epitaxial wafer suppliers. Emerging applications in 5G communications, IoT devices and HPC also widen the scope for epitaxial wafer usage.

Threats: Trade barriers and geopolitical issues can negatively impact the supply chain of epitaxial wafer suppliers. Price competition from regional players and capability of providing diverse portfolio of technologies also pose threats. Intense capital requirements for expanding 8-inch and 12-inch wafer fabrication units can limit industry participants.

Key Takeaways

The global epitaxial wafer market analysis is expected to witness high growth over the forecast period supported by increasing demand for optoelectronics and photovoltaic applications. The market size is projected to reach US$ 938.32 Bn by 2023 growing at a CAGR of 4.8% between 2023 and 2030.

Regional analysis: Asia Pacific dominates the global epitaxial wafer market currently accounting for over 50% share due to presence of leading manufacturers in Taiwan, China and South Korea. The region is expected to maintain its dominance attributed to growing consumption of smartphones, wearables and expanding LED lighting industry. The North America and Europe markets are also expected to grow at a steady pace supported by presence of automobile and consumerelectronics manufacturers.

Key players: Key players operating in the epitaxial wafer market are EpiWorks Inc., Global Wafers Japan Co. Ltd., Nichia Corporation, SHOWA DENKO K.K., Siltronic AG, Desert Silicon Inc., Electronics and Materials Corporation Ltd. Intelligent Epitaxy Technology Inc.IQE plc., Jenoptic AG, MOSPEC Semiconductor Corporation, Norstel AB, Ommic S.A., Silicon Valley Microelectronics Inc., SVT Associates Inc. Universal Wafer Inc., Wafer Works Corporation, Xiamen Powerway Advanced Materials Co. Ltd., and Visual Photonics Epitaxy Co. Ltd. The market is relatively concentrated with top players focusing on expanding manufacturing facilities and providing diverse technology offerings to customers.

Get more insights on this topic: https://weblogmarketinsights.blogspot.com/2023/12/the-global-epitaxial-wafer-market.html

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Oyunlar

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness

- IT, Cloud, Software and Technology