Polymers for Additive Manufacturing is Estimated to Witness High Growth Owing to Opportunity in Medical Implants

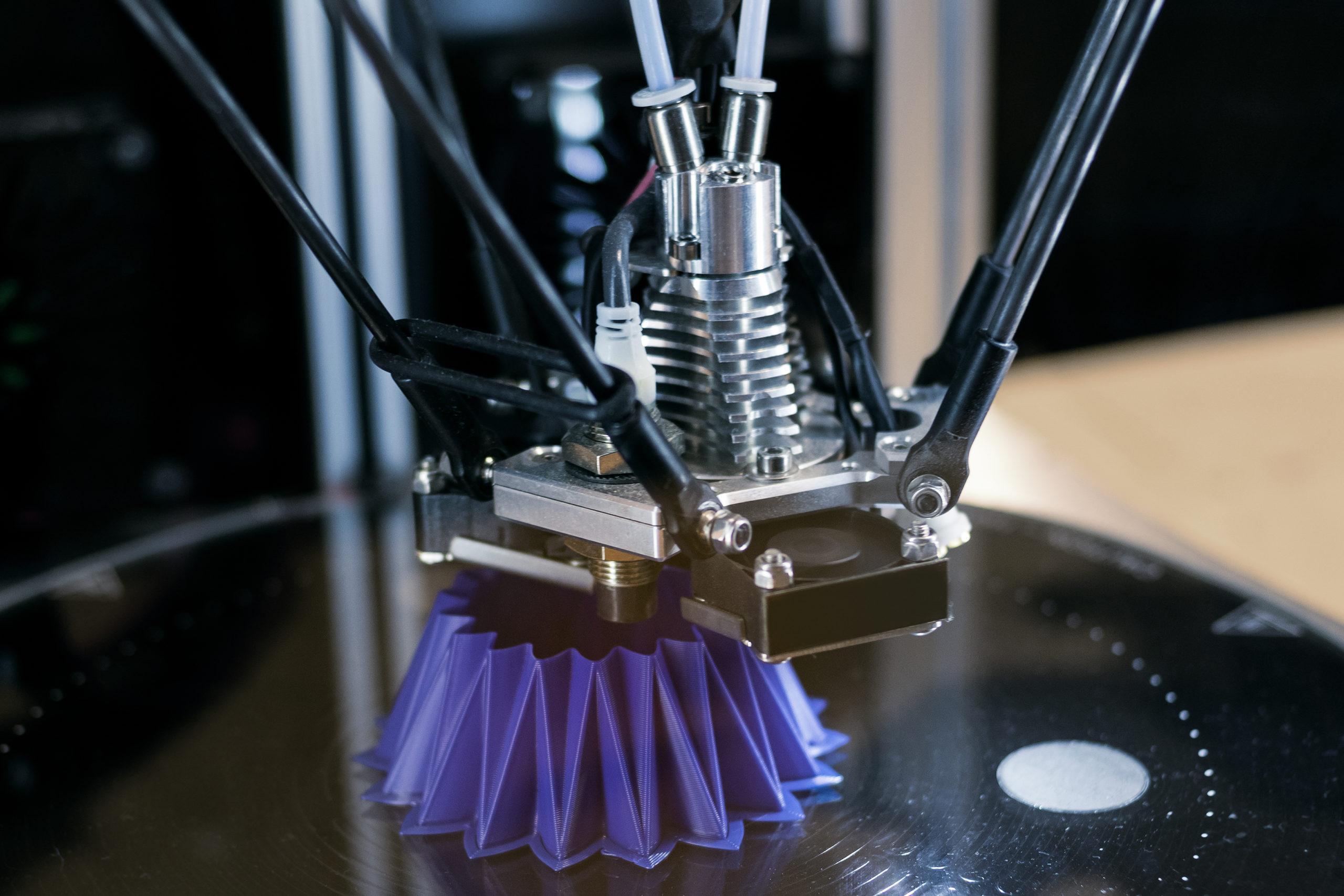

Additive manufacturing, also called 3D printing, is a manufacturing process that builds three-dimensional objects using digital CAD files. The key benefit of additive manufacturing is its ability to produce complex geometries that are difficult or impossible to manufacture any other way. Polymers for additive manufacturing include photopolymers, thermoplastics, elastomers, and biomaterials that are used to 3D print objects through various additive manufacturing technologies like stereolithography, fused deposition modeling, material jetting, binder jetting, material extrusion, powder bed fusion, and sheet lamination. Polymers are favored for additive manufacturing as they are widely available, affordable to produce, easy to modify, lightweight, and can achieve different material properties.

The global Polymers for Additive Manufacturing Market is estimated to be valued at US$ 337.84 Mn in 2023 and is expected to exhibit a CAGR of 23.% over the forecast period 2023 to 2030, as highlighted in a new report published by Coherent Market Insights.

Market Opportunity:

The increasing demand for customized medical implants created using additive manufacturing offers huge market potential for polymers used in this application. Additive manufacturing allows fabrication of personalized, patient-specific anatomical geometry that traditional techniques fail to match. Implants created through 3D printing with biocompatible polymers have improved mechanical properties and biocompatibility. This reduces rejection rates and healing time post-surgery. The customizable nature and ability to produce complex geometries to precisely fit replacement parts in the body using polymers has boosted their use in medical implants like hip and knee replacements, dental implants, tissue engineering scaffolds and hearing aids. This growing need for personalized medicine through customized medical implants will help drive the polymers for additive manufacturing market substantially over the forecast period.

Porter's Analysis

Threat of new entrants: Low-moderate as significant capital required for R&D, production facilities and machinery. However, entry barrier is reducing due to 3D printing becoming mainstream.

Bargaining power of buyers: Moderate. Buyers have higher bargaining power due to availability of substitutes and competition. However, customized solutions enhance switching costs.

Bargaining power of suppliers: Moderate-high. Suppliers of raw materials like polymers, resins have influence over prices due to consolidated supply base. Regulatory compliance further limits supplier alternatives.

Threat of new substitutes: Low-moderate. Additive manufacturing offers advantages over conventional methods for prototyping and customized production. However, traditional injection molding poses threat for mass scale production.

Competitive rivalry: High. Intense competition exists among established players to diversify product portfolio and target new applications.

SWOT Analysis

Strengths: Ability to make complex designs, reduce waste, customized solutions, and lower costs for prototyping.

Weaknesses: High initial investment, limited production size, regulatory uncertainties over new materials.

Opportunities: Expanding into end-use industries like aerospace, healthcare, automotive thanks to benefits of 3D printing. Growing research on bio-based materials.

Threats: Competition from injection molding for mass production. Stringent safety and performance standards delay commercialization.

Key Takeaways

The Global Polymers For Additive Manufacturing Market Size is expected to witness high growth. The global polymers for additive manufacturing market is estimated to be valued at US$ 337.84 Mn in 2023 and is expected to exhibit a CAGR of 23.% over the forecast period 2023 to 2030.

The North American region currently dominates the polymers for additive manufacturing market owing to high adoption across various industries. Asia Pacific is poised to be the fastest growing market owing to expansion of application industries and government support for additive manufacturing adoption in the region.

Key players related content (Key players operating in the Polymers for Additive Manufacturing market are Arkema S.A., Covestro AG, DuPont, Inc., EOS GmbH, Evonik Industries AG, INTAMSYS, Prototal Industries, Stratasys Ltd., BASF SE, Saudi Basic Industries Corporation (SABIC), Huntsman International LLC., NatureWorks LLC. Stratasys and 3D Systems are the established players focusing on expanding polymer material portfolio and production capacities to tap market opportunities.

Get more insights on this topic:

https://www.zupyak.com/p/3960315/t/the-global-polymers-for-additive-manufacturing-market-growth-accelerated-by-expanded-application-scope

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Giochi

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Altre informazioni

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness

- IT, Cloud, Software and Technology