CVD Silicon Carbide Market Is Estimated To Witness High Growth Owing To Rising Adoption In Semiconductor Industry

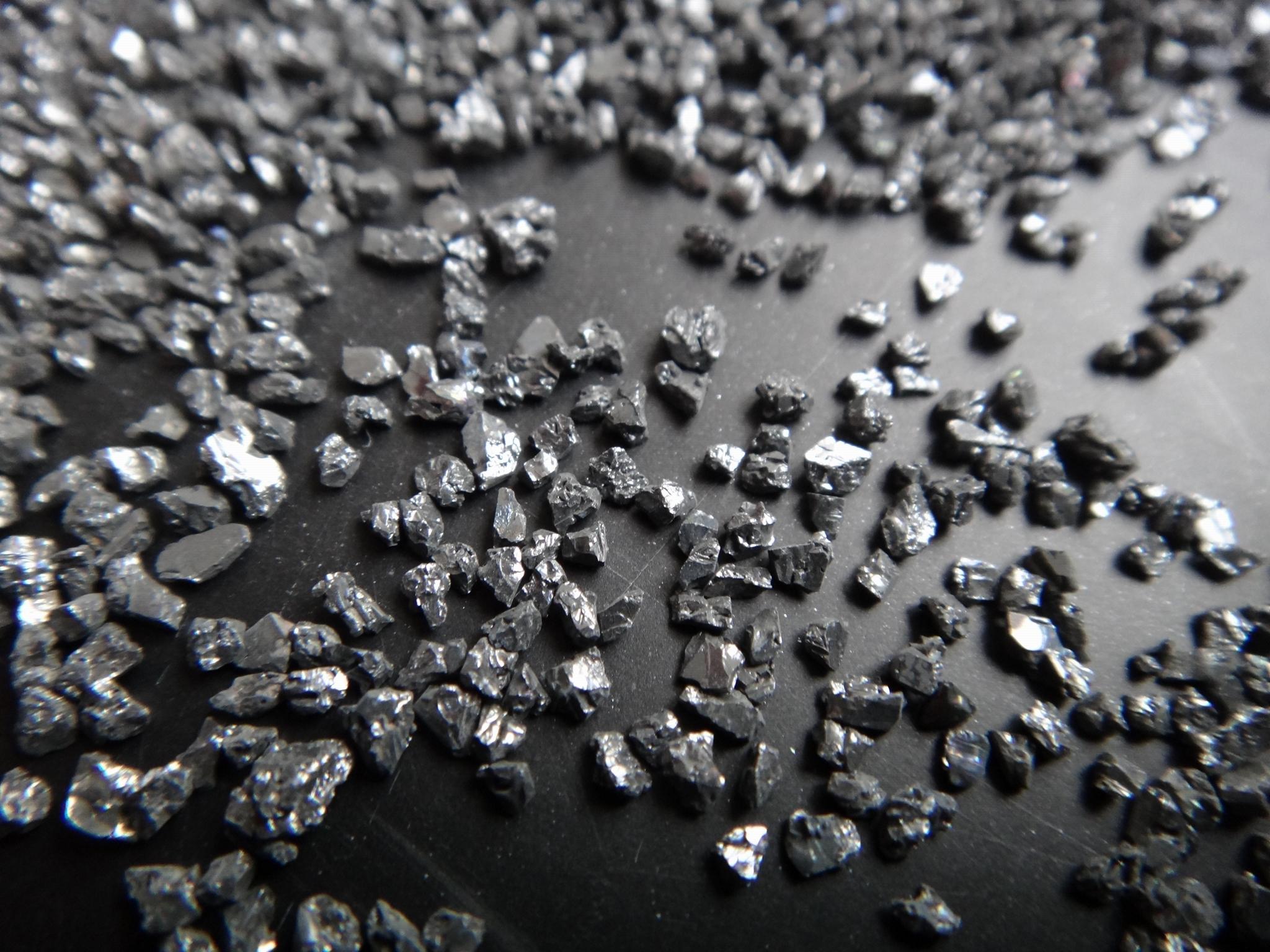

Chemical vapor deposition (CVD) silicon carbide is a compound semiconductor material that provides unique properties such as high thermal conductivity, high electric field breakdown strength, wide bandgap, high electron mobility, and excellent thermal stability, making it suitable for applications in power electronics, solar cells, and sensors. CVD silicon carbide is used to make wafers, which are then used to manufacture semiconductors for various electronic components. The growing demand for semiconductor devices from end-use industries such as automotive, consumer electronics, and industrial has resulted in increased adoption of CVD silicon carbide.

The global CVD Silicon Carbide Market is estimated to be valued at US$ 643.6 Mn in 2023 and is expected to exhibit a CAGR of 6.8% over the forecast period 2023 to 2030, as highlighted in a new report published by Coherent Market Insights.

Market Dynamics:

The rising adoption of semiconductor devices in various industries is majorly driving the growth of the CVD silicon carbide market. Semiconductors manufactured using CVD silicon carbide offer better conductivity, high voltages, fast switching, and operate efficiently at high temperatures. This increases their adoption in power electronics that are used in automobile components, industrial motor drives, solar panels, and military applications. Additionally, growing demand for SiC devices from the electric vehicle market is also fueling market growth. SiC MOSFETs and diodes allow greater power conversion efficiency and smaller heat sinks in EVs as compared to silicon counterparts. However, high costs associated with manufacturing equipment and materials for SiC substrates pose a challenge to market growth.

SWOT Analysis

Strength: CVD silicon carbide has exceptional physical and chemical properties such as high melting point, high hardness, excellent oxidation and corrosion resistance which make it suitable for use in high temperature applications. It can withstand temperatures as high as 1400°C without degradation. The material also has high strength and modulus helping components to operate efficiently at elevated temperatures without failures. Its ability to handle extreme operating conditions make it preferable over other materials in several industrial processes.

Weakness: CVD silicon carbide is an expensive material to produce compared to other ceramic materials owing to the complex chemical vapor deposition process involved. The manufacturing process requires high capital investment and operating costs. Additionally, fine tuning of process parameters is needed to synthesize defect-free coatings which increases production challenges.

Opportunity: Increasing demand from the semiconductor industry for use as substrates in manufacturing of LEDs and for thermal management of power devices offers significant growth prospects. Rising requirement for high temperature resistant coatings in gas turbines, diesel engines and other industrial plants where resistance to thermal shocks and corrosion is critical also provides opportunities. Growth of the solar industry utilizing silicon carbide in manufacturing of high efficiency photovoltaic cells will further boost the market.

Threats: Availability of alternative ceramic materials like aluminum oxide which have satisfactory high temperature properties at lower costs can threaten the silicon carbide market share. Development of new deposition techniques enabling mass production of aluminum nitride at reduced costs poses challenges. Dependence on limited number of manufacturers for key raw materials and lack of domestic production capacities in many regions are other threats.

Key Takeaways

The global CVD Silicon Carbide Market is expected to witness high growth over the forecast period supported by rising use of SiC substrates in LED manufacturing and for thermal management of power electronics devices. The semiconductor industry dominates the application segments and ongoing advancements expanding usage of wide bandgap technologies will propel demands. The global CVD Silicon Carbide Market is estimated to be valued at US$ 643.6 Mn in 2023 and is expected to exhibit a CAGR of 6.8% over the forecast period 2023 to 2030.

Regional analysis: Asia Pacific currently holds the major market share and is projected to maintain its dominance due to the large manufacturing bases of semiconductor fabrication, solar and industrial equipment in countries like China, Taiwan and South Korea. Government initiatives promoting adoption of wide bandgap semiconductors also support regional growth. Europe and North America are other major consumer markets driven by extensive research and development activities coupled with presence of key players.

Key players: Key players operating in the CVD silicon carbide market are FLSmidth & Co. A/S, Metso Oyj, Koppern Group, CITIC Heavy Industries Co. Ltd. (CITIC HIC), ThyssenKrupp Industrial Solutions AG (Polysius AG), SGS S.A., KHD Humboldt Wedag International AG, Outotec Oyj, and ABB Ltd. The market is consolidated in nature with these top players accounting for majority share.

Get more insights on this topic: https://www.timessquarereporter.com/business/the-global-cvd-silicon-carbide-market-growth-accelerated-by-infrastructure-development-and-automotive-industry-growth

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Jeux

- Gardening

- Health

- Domicile

- Literature

- Music

- Networking

- Autre

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness

- IT, Cloud, Software and Technology