Medical Drying Cabinets: Essential For Sterilizing Medical Equipment

Medical drying cabinets have become an essential piece of equipment for any medical facility that requires sterilizing medical instruments and equipment. These cabinets provide a controlled environment for safely drying sterile equipment after it has gone through the sterilization process. With the importance of maintaining sterility and preventing contamination, medical drying cabinets are a necessary investment for clinics, hospitals, dental and medical offices.

What is a Medical Drying Cabinet?

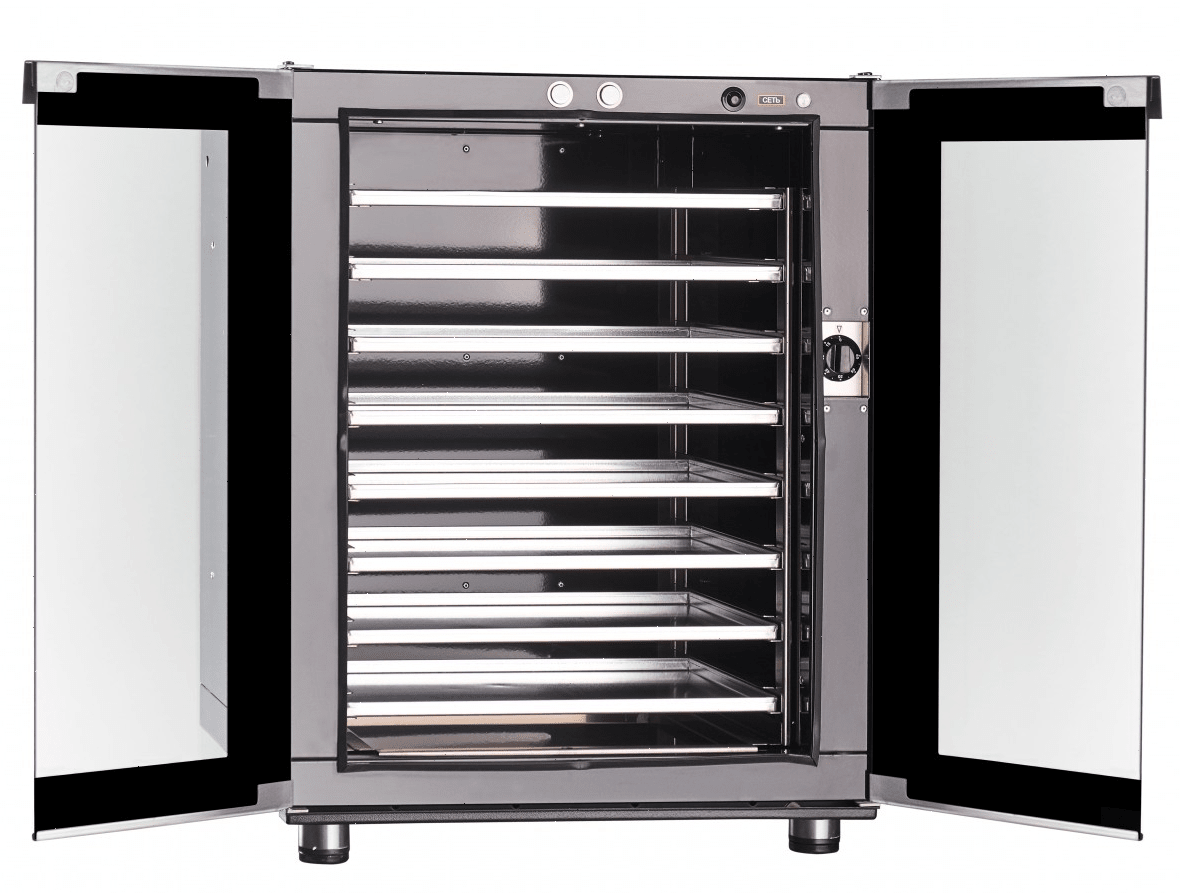

A medical drying cabinet is a heavily insulated storage unit that is designed specifically for drying medical equipment and instruments after they have been sterilized. Modern medical drying cabinets use heated airflow to gently dry items in a controlled, sterile environment. The cabinets maintain precise temperature, airflow and humidity levels to eliminate any possibility of condensation or bacterial growth on equipment during the drying phase.

Medical drying cabinets come in various sizes to accommodate the specific sterilization needs of different medical facilities. For small clinics or dental practices, undercounter cabinets provide enough drying capacity. Larger roll-in cabinets are suitable for busy hospital sterilization rooms where high volume equipment processing is required. All medical drying cabinets are designed for easy loading and unloading of treated items on sliding shelves or racks.

Importance of Proper Drying

After sterilization through processes like autoclaving, steam sterilizers or STERIS sytems, moist medical equipment must be dried thoroughly before storage and use. If items are not dried completely, moisture trapped inside packaging could lead to bacterial growth jeopardizing sterility. Condensation inside packaging is also a contamination risk that can transmit infectious organisms to patients.

Proper drying is therefore a critical step in the sterilization workflow that cannot be overlooked or rushed. Using a medical drying cabinet ensures equipment is dried slowly and gently in a closed, sterile environment. Cabinets maintain precise temperature and airflow until moisture levels drop below recommended safe storage limits. This eliminates any possibility of contamination issues from residual moisture.

Benefits of Medical Drying Cabinets

There are several important benefits that medical facilities gain from utilizing a medical drying cabinet:

- Maintains Sterility - The controlled environment effectively sterilizes items without reintroducing moisture that could compromise sterility. This minimizes risk of healthcare-associated infections.

- Saves Time - Cabinets quickly and efficiently dry full loads of processed equipment without requiring direct supervision. Staff time is freed up for other tasks.

- Standardizes Process - Integrated controls ensure consistent drying conditions meeting established protocols each time. This simplifies compliance with sterilization standards.

- Extends Shelf Life - Properly dried items maintain sterility over longer storage periods until point of use compared to air drying. This reduces waste fromexpired sterile stock.

- Protects Investment - Prevents cost of reprocessing equipment if sterility is breached due to inadequate or improper drying. Savings offset cost of the drying cabinet over time.

Key Features of Leading Medical Drying Cabinets

When selecting a medical drying cabinet, facilities should consider models with the following recommended features:

- Double-door Access - Allows easy loading and unloading of multiple instrument trays or carts without exposing interior sterile air.

- Precision Temperature Control - Microprocessor maintains ±2°C of set point between 40-180°C throughout drying cycle.

- Adjustable Shelves - Rack configurations can be modified as needed to maximize loading space.

- Integral Drying Process Timer - Ensures minimum drying times are completed before releasing load for storage.

- Easy-Clean Interiors - Smooth surfaces and tight seams between panels simplify cleaning and decontamination between loads.

- Validation Capabilities - Integrated data logging and documentation capabilities facilitate process validation requirements.

- Alarm Systems - Audible/visual alerts advise staff of errors, completed cycles or other program deviations.

Choosing a reputable manufacturer ensures cabinets are designed and built specifically for the harsh, humid conditions within medical facilities. Certifications like UL, CSA and CE Marking demonstrate units meet stringent safety requirements.

Spending on Quality Pays Off

While medical drying cabinets carry an upfront equipment cost, investing in a name brand unit from a quality manufacturer ultimately saves medical facilities money. Properly dried sterile equipment stays ready for immediate use longer instead of being prematurely discarded due to compromised sterility or moisture concerns if air dried. Professional drying cabinets also get expensive equipment back into the sterilization queue more quickly.

The protective sterility and standardized processes delivered by modern medical drying cabinet systems easily justify their costs. By preserving huge financial investments in instruments and devices, cabinet purchases repay their own expense many times over through extended usability of facility sterilization assets. For delivering guaranteed sterility directly impacting quality patient care, medical drying cabinets are worth every penny.

In summary, the controlled drying of medical equipment after sterilization is a vital but often overlooked part of the sterilization workflow. Medical drying cabinets provide facilities a reliable, cost-effective solution for this critical step by ensuring sterility is fully maintained until the point of use. Their many benefits easily offset the initial purchase cost, making cabinet systems an indispensable investment for any medical provider serious about infection control.

Get more insights on this topic: https://www.newsanalyticspro.com/medical-drying-cabinets-ensuring-efficiency-and-safety-in-medical-facilities/

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Jogos

- Gardening

- Health

- Início

- Literature

- Music

- Networking

- Outro

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness

- IT, Cloud, Software and Technology