Management of Auto Parts Based on RFID Technology

As a typical situation in discrete industrial production, the device production activities of cars have the following characteristics: the production process is parallel and asynchronous, the equipment function redundancy is large, the amount of control is independent of each other, the management of production resources is complex, the parts and components in the production process are in a discrete state, and the production of cars and vehicles is mainly completed through physical processing and assembly. Oprfid technologies believes that bar code technology is the primary application in the car assembly line. The station staff manually scan the VIN code of the car body and the bar code of parts for vehicle tracking and device information collection. The whole collection process is relatively time-consuming. When the barcode is damaged, stained and unrecognizable, employees need to manually enter the vehicle VIN code or part code, which has a high error rate and takes a long time, making it difficult to speed up the production pace. The visualization level of the production site needs to be improved. It is necessary to provide real-time and accurate device guidance for workers to eliminate the phenomenon of missing and wrong installation. It is also necessary to monitor the device status of vehicles on the production line in real time. The material consumption information is not reflected in time, which makes it difficult to complete the real-time pulling of production materials, resulting in excessive inventory of production materials and affecting capital activities. The lack of relevant handling of employees and their device parts makes it difficult to assign responsibilities to people when tracing quality problems caused by manual operation.

RFID technology (passive RFID tag, radio frequency identification) is not just a simple replacement of bar code technology. Its application in discrete manufacturing industry will change the production and management methods of discrete manufacturing enterprises. Because RFID technology has many advantages mentioned above, it can replace bar code to mark and track vehicles on the car production line. There is no manual intervention in the whole process, which can greatly reduce the labor intensity and error rate of workers. Nowadays, it has been able to use oprfid technologies RFID asset management system to complete active, high-speed and useful records, reduce the labor intensity of operators, and then improve the product offline qualification rate.

Applying RFID technology (passive RFID tag, radio frequency identification) to the car manufacturing industry and integrating it into the MES system can improve the management and control level of the production process, and effectively monitor, handle and control the resources including materials, equipment, manpower and so on required for production; Combined with the upper management system, these resources can be reasonably scheduled and handled, so as to improve the production competitiveness, improve the production organization, shorten the production cycle, reduce the number of products in process, improve the quality of products and reduce the consumption of human resources. Oprfid technologies has important theoretical significance and application value for developing the production system form and application processing scheme of discrete production industry, improving the visual monitoring of production process and the pursuit level of product quality, promoting the application of standard composition of RFID skills in production industry, and driving the industrialization of RFID asset management in China.

2 RFID asset management system policy

According to the above demand analysis, the following general policy of the system is put forward: make full use of the technical advantages of RFID and combine the MES system of the general assembly workshop to deal with the problems between the scheme level of the current ERP system of the enterprise and the process control level of the on-site automation system of the workshop, between the internal logistics level of the LES (logisticexecutionsystem) workshop and the production control level of the MES system The information and management gap between the vehicle quality traceability system and the original MES system, the completion of production and the visualization and digital management of quality. It is divided into the following sub policies in detail:

(1) Combine RFID skills with production line scheduling system, and complete the intellectualization of production line scheduling based on the automation of production line scheduling.

(2) Integrate RFID skills into the device station of the production workshop, use RFID tags to identify parts for data collection, grasp the material consumption information of the production line in time, pull the supply logistics without delay, and further meet the demand of JIT supply form; Device records of important components provide detailed and reliable data support for the quality traceability system.

(3) Combine RFID skills with on-site visualization system to provide real-time and accurate device guidance to station workers.

(4) Combining RFID skills with workshop personnel handling system and quality traceability system, in addition to the function of completing personnel handling, it can also record the operation of the device and implement the responsibility of completing the device to people.

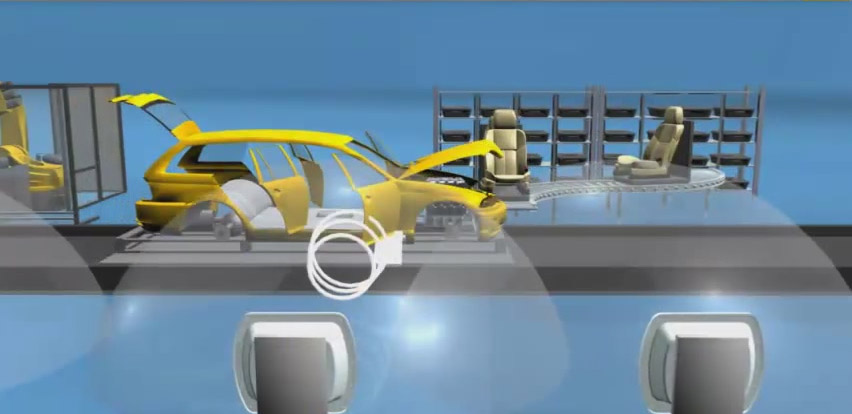

3. Application scheme of RFID technology in car assembly line

The application scheme involves two different types of RFID Tags: high frequency (13.56MHz) and ultra-high frequency (915MHz), and the selected RFID tag standard

During this period, personnel are equipped with high-frequency RFID tags, which store employee ID and basic information; A high-frequency RFID tag is placed in the material box of each part, and the part number is stored in the tag; An UHF RFID tag is placed on each vehicle, and only the identification code (VIN code) of the vehicle is stored in the tag. The vehicle label is sealed with glue and magnet, which is convenient to be adsorbed on the exterior of the vehicle body.

Before the vehicle goes online, the staff will put the initialized label device on the front of the car body and the hood.

The production line employees need to swipe their cards on the high-frequency card reader on the station to complete the job certification, and the system records the job status information of the station employees at that time.

Before the vehicle goes online, the staff scans the VIN bar code of the vehicle body, and the UHF reader writes the VIN code information into the vehicle RFID tag within the antenna field strength range. The subsequent stations finish the vehicle monitoring and data collection of the production line by reading and writing the RFID tag of the vehicle body.

At the device station, the UHF reader/writer will prompt the component device information of the corresponding station after reading the vehicle label. The staff installed the corresponding parts and brushed the high-frequency RFID tags in the material box of the corresponding parts on the high-frequency reader writer. The system obtains the component device information and staff information of the corresponding vehicle for later quality monitoring. The system returns the material consumption information to the LES system, and rewrites the information prompt of the station component device until all the components that should be installed at the station are installed. In the supply process to the production line station, the system updates the quantity information of parts after the production line logistics department delivers the parts to the station.

In the offline position, the UHF reader reads the vehicle tag, the system checks the device information, and the staff removes the RFID tag for recycling.

4. Car assembly production performance system based on RFID (electronic tag, radio frequency identification) skills

4.1 function module of RFID asset management system

According to RFID skills, the function module of car assembly production performance system is mainly divided into four function modules: workshop production management, production line visualization, RFID tag management, workshop personnel management.

Handling of workshop personnel: handle the basic information of workshop personnel and the job information of equipment workers, and provide relevant basic data for the functions of workers' work records and vehicle parts data acquisition.

Production management of General Assembly Workshop: obtain coarse-grained production plan from ERP system at the scheme level, differentiate into daily production plan, and guide workshop production. Coach and monitor each device step of the vehicle in the production process of the whole vehicle to standardize the whole production process, including providing device operation guidance to device workers, automating the collection of device and material consumption data of the whole vehicle, providing device records accurate to parts information, device personnel information and supplier information, and reflecting the consumption data of station materials to the MES system in real time.

Production line visualization: provide real-time reflection of production line and vehicle status information, which is conducive to the management personnel to grasp the production status in real time.

RFID tag handling: responsible for the distribution and handling of personnel tags, the distribution and recycling of tags in the recycling of vehicle tags, and the asset handling of vehicle tags.

4.2 architecture

This system uses RFID software middleware deployed in the workshop server to handle the workshop reader writer network in a unified way, which is conducive to shielding the differences of RFID devices, improving the stability and power of desktop RFID reader writer network, and RFID devices do not rely on station terminals, so there is no need to specially equip station terminals, which is convenient for deployment.

OPRFID Technology Online Website:

More RFID Technology Articles:

http://smartsourcing.ru/blogs/poleznye_tehnologii_i_produkty/10456

https://www.tedpublications.com/forum/showthread.php?tid=104610

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Oyunlar

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness

- IT, Cloud, Software and Technology