The Foundation of Strength: Exploring the Versatility of Mild Steel Plates in Construction

Mild steel plates, with their remarkable combination of strength, formability, and affordability, serve as essential building blocks in construction projects around the world. From structural frameworks to industrial machinery, these plates play a pivotal role in providing stability, support, and durability to a great many structures and applications. In this article, we dive into the characteristics, applications, and advantages of mild steel plates, highlighting their significance in shaping the built environment.

Understanding Mild Steel Plates

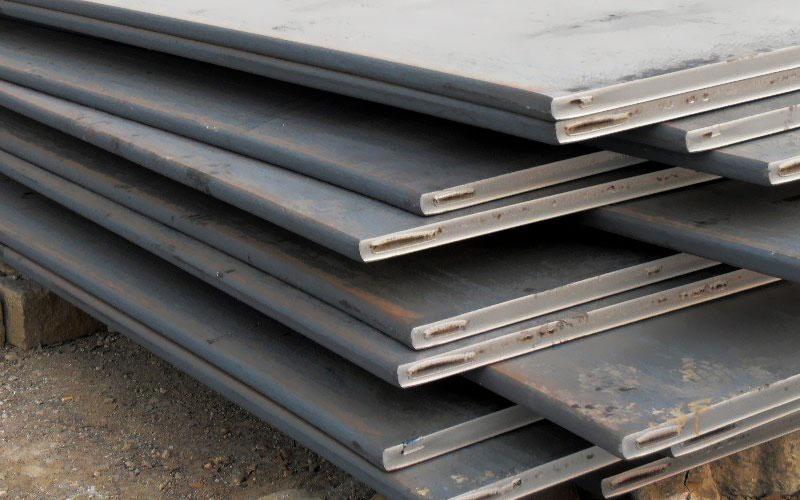

Mild steel plates, also known as low carbon steel plates, are flat sheets of steel with a thickness ranging from a couple of millimeters to several inches. They are typically manufactured from low-carbon steel, which contains a small percentage of carbon along with other alloying elements like manganese, phosphorus, and sulfur. Mild steel plates are delivered through hot rolling or cold rolling cycles, resulting in exact aspects and smooth surfaces.

Characteristics of Mild Steel Plates

Mild steel plates have several characteristics that make them suitable for an extensive variety of construction applications:

-

High Strength: Despite their low carbon content, mild steel plates offer high elasticity and great impact resistance, making them capable of withstanding heavy loads and structural burdens.

-

Formability: Mild steel plates exhibit amazing formability, allowing them to be easily bent, shaped, or welded to suit explicit undertaking prerequisites. This formability facilitates customization and versatility in construction applications, including structural frameworks, machinery components, and architectural detailing.

-

Corrosion Resistance: While mild steel is powerless to corrosion, appropriate surface treatments like painting or galvanizing can enhance the corrosion resistance of plates, making them suitable for both indoor and open air applications.

-

Cost-Effectiveness: Mild steel plates are cost-powerful building materials compared to alternatives like stainless steel or aluminum. Their affordability makes them a favored decision for various construction projects without compromising on quality or performance.

Applications of Mild Steel Plates

The versatility and performance of mild steel plates make them indispensable in various construction projects across different industries:

-

Structural Frameworks: Mild steel plates are normally utilized in the construction of structural frameworks for buildings, bridges, and industrial facilities. They serve as columns, beams, and trusses, providing essential reinforcement and stability to the overall construction.

-

Industrial Machinery: Mild steel plates find broad use in the manufacturing of industrial machinery and equipment. They are utilized in the construction of machinery components like base plates, frames, and structural supports, ensuring the strength and reliability of industrial machinery in assorted applications.

-

Shipbuilding: Mild steel plates are essential in the shipbuilding industry, where they are utilized to fabricate hulls, decks, bulkheads, and other structural components of ships and offshore structures. Their high strength and durability make them suitable for withstanding the harsh marine environment and dynamic loading conditions.

-

Storage Tanks and Pressure Vessels: Mild steel plates are generally used in the construction of storage tanks, pressure vessels, and pipelines for storing and transporting fluids and gases. Their strength, formability, and corrosion resistance make them ideal materials for containing and conveying various substances in industrial and commercial settings.

-

Automotive and Transportation: Mild steel plates play a vital role in the automotive and transportation industries, where they are utilized to manufacture vehicle bodies, chassis, and structural components. Their strength, formability, and impact resistance add to the safety, performance, and durability of automobiles, trucks, trains, and other transportation vehicles.

Advantages of Mild Steel Plates

The adoption of mild steel plates in construction offers several advantages:

-

Strength and Durability: Mild steel plates give high rigidity and astounding impact resistance, ensuring long-term structural integrity and resistance to deformation under heavy loads.

-

Versatility: Mild steel plates are available in various sizes, thicknesses, and grades, making them versatile for an extensive variety of construction applications. Whether utilized for structural frameworks, machinery components, or storage tanks, mild steel plates offer flexibility in plan and implementation.

-

Ease of Fabrication: Mild steel plates are easily fabricated, allowing for effective customization and adaptation to explicit undertaking necessities. They can be cut, welded, penetrated, and framed with relative ease, enabling fast and exact construction processes.

-

Cost-Effectiveness: Mild steel plates offer cost-powerful answers for construction projects without compromising on quality or performance. Their affordability makes them a favored decision for manufacturers and contractors seeking economical building materials.

-

Recyclability: Mild steel is a highly recyclable material, contributing to sustainability endeavors in the construction industry. At the finish of its administration life, mild steel plates can be reused and reused, reducing environmental impact and conserving natural assets.

Conclusion

In conclusion, mild steel plates are versatile and reliable building materials that play a crucial role in modern construction. From structural frameworks to industrial machinery, these plates serve as essential components in various applications across different industries. With their high strength, formability, and affordability, mild steel plates continue to shape the built environment, providing stability, support, and durability to construction projects worldwide. As we continue to advance in engineering and innovation, mild steel plates will without a doubt remain a cornerstone of modern construction practices, empowering us to fabricate a better, stronger future for generations to come.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- الألعاب

- Gardening

- Health

- الرئيسية

- Literature

- Music

- Networking

- أخرى

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness

- IT, Cloud, Software and Technology