Conducting Accelerated Aging Tests with UV Accelerated Aging Chamber and Evaluating Bottle Closure Integrity with Torque Tester

In industries where the quality and durability of materials are paramount, such as textiles, metals, polymers, and bottle packaging, conducting thorough testing procedures is essential. Manufacturers rely on advanced lab testing instruments to assess the resilience of materials against environmental factors such as UV light, moisture, and physical stress. Presto Group offers two such innovative instruments: the UV Accelerated Aging Chamber and the Torque Tester. Let's explore how these instruments function and their significance in ensuring product quality:

UV Accelerated Aging Chamber: Testing Material Durability

The UV Accelerated Aging Chamber is designed to simulate the effects of prolonged exposure to UV light, moisture, and heat on materials. Its working mechanism involves three distinct testing cycles:

- Dry Cycle: Subjects the specimen to elevated temperatures and UV light to simulate dry environmental conditions.

- Condensation Cycle: Creates a controlled moisture-rich atmosphere around the specimen by introducing demineralized water into the testing chamber.

- Spray Cycle: Sprinkles demineralized water onto the specimen to simulate moisture and corrosion exposure.

Key Features:

- Incorporation of UVA and UVB lamps for uniform light distribution.

- Inlet and drainage ports for controlled water supply and extraction.

- Safety alarms to minimize human intervention and ensure testing accuracy.

- HMI-based touchscreen for easy operation and data analysis.

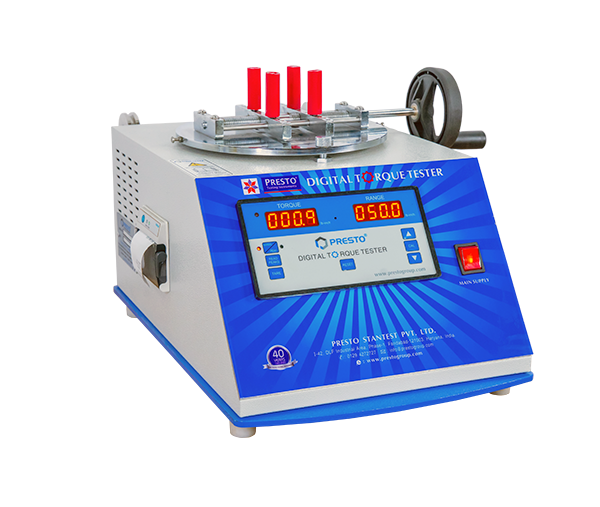

Torque Tester: Assessing Bottle Closure Integrity

The Torque Tester is specifically designed to evaluate the torque required to open or close bottle closures. This test is crucial for assessing seal integrity and preventing over-tightening, especially in industries like beverage packaging. Its working module involves precise clamping of the bottle onto the platform, followed by manual opening of the closure.

Key Features:

- Safety pin for precise platform positioning.

- Tightening knobs to prevent slippage and ensure accurate testing.

- Single-handed operation for convenience.

- Robust stainless steel construction for durability.

- Microprocessor-based digital display for precise torque measurement.

FAQs About Torque Tester

Q: What is the purpose of the torque test? A: The torque test assesses the rotational force required to open or close bottle closures, ensuring seal integrity and consumer satisfaction.

Q: Which standard does the Presto torque tester comply with? A: The torque tester adheres to ASTM D7860 – 14 (2022) standards, among others.

Conclusion

Both the UV Accelerated Aging Chamber and the Torque Tester play integral roles in ensuring the quality and durability of materials and products across various industries. By subjecting materials to rigorous testing procedures, manufacturers can identify weaknesses, enhance product quality, and ultimately deliver superior products to consumers. To acquire these advanced lab testing instruments and elevate your quality assurance processes, contact Presto Group today.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Giochi

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Altre informazioni

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness

- IT, Cloud, Software and Technology