3 Key Points to Know What are Laboratory Freeze Dryers

Freeze-drying technology has gained widespread prominence across various industies, including medicine, biology, food production, active substances, and nanomaterials. Laboratory freeze dryers have become indispensable tools in research and development, testing applications, and experimental scientific inquiries. These freeze dryers are extensively employed in diverse industries, ranging from bio-cosmetics and pharmaceuticals to food and nanomaterials, enabling the preservation of biological activity and substance structure. This article delves into the fundamental principles of freeze drying, its applications, and the key features of laboratory freeze dryers.

Freeze Drying: Preserving Items through Sublimation

Freeze drying, also known as sublimation drying, involves the removal of moisture from items to prevent deterioration. The deterioration of items results primarily from external and internal factors such as air, water, temperature, and biological processes. By minimizing the impact of these factors, the aim is to maintain items' integrity over a specific period.

To facilitate extended storage, moisture, a vital component for the growth of living organisms, needs to be eliminated from the items. Reducing the water content hinders the growth and reproduction of organisms, thereby preserving them. Additionally, water can catalyze chemical reactions leading to item deterioration.

Characteristics of Laboratory Freeze Dryers

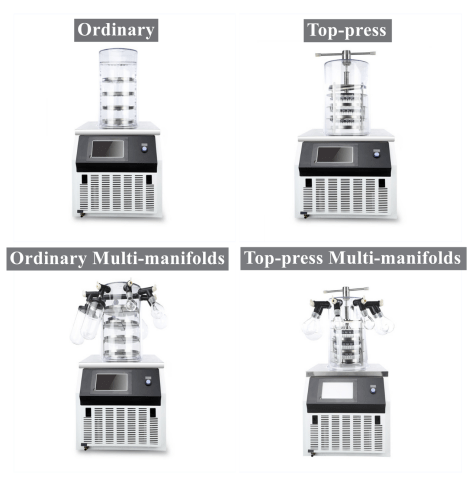

Laboratory freeze dryers are available in various configurations, each tailored to specific needs:

Ordinary Type: Suitable for a wide range of materials, items are placed directly on the material tray for freeze drying.

Gland Type: Designed for drying materials in vials, it ensures a vacuum-sealed environment post-drying.

Multi-Manifold Type: When multiple materials must be dried separately, this type prevents interference and enables easy observation and sampling.

Multi-Manifold Gland Type: This type accommodates diverse materials, some processed in vials, while others undergo different treatment methods.

Small In-Situ Pre-Freeze Type: It offers easy-to-use features such as one-button start, adjustable temperature, program operation, and automatic control, suitable for in-situ pre-freeze drying.

Preparation and Maintenance

Before using a freeze dryer, several crucial steps must be taken:

Verify the power supply voltage is correct.

Ensure accurate placement of the temperature measurement camera in the drying chamber.

Check vacuum pump oil quality and quantity.

Inspect gate valves in the ultrafiltration device for correct functionality.

Confirm clean drainage of defrosting water from the cold trap.

For maintaining a laboratory freeze dryer:

Strict adherence to usage and maintenance guidelines is vital.

Regular checks and replacements of lubricating grease are essential, influenced by compression end temperatures.

Lubricating oil should be inspected every 10,000 hours of continuous operation.

During maintenance, clean the refrigeration system if the motor burns out to prevent impurity dispersion.

System-wide inspections should include the filtration system, and components should be replaced if necessary.

After compressor overhauls, dehumidify the system using dry nitrogen and vacuum treatment to enhance operational efficiency.

System leaks are common sources of refrigeration system failures; prioritize leak testing and pressure maintenance.

In case of equipment failure, a thorough investigation is necessary, and professional assistance should be sought if needed. Neglecting proper maintenance may lead to detrimental long-term effects on compressor operation and system efficiency, underscoring the importance of vigilant care.

Conclusion

Laboratory freeze dryers are pivotal tools in various scientific and industrial applications, aiding in the preservation of biological activity and structural integrity. Understanding the principles, characteristics, and proper maintenance practices of lab freeze dryers ensures efficient and effective freeze-drying processes for a diverse array of materials.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Giochi

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Altre informazioni

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness

- IT, Cloud, Software and Technology