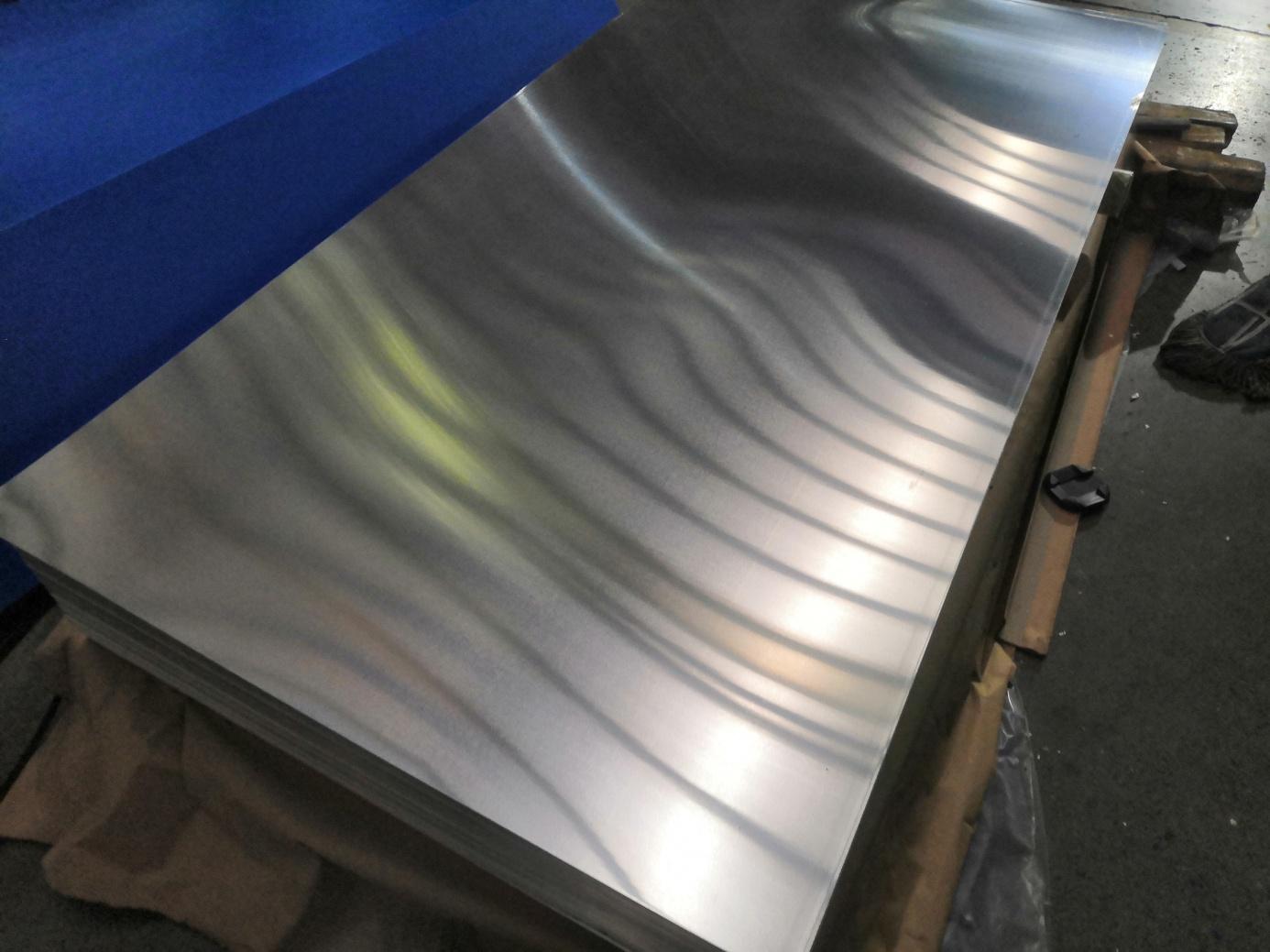

Giant blessings of aluminium sheet for mould

Aluminium sheet for mould 5052, 6061 and 7075 are extensively used in eighty% of various mould industries including injection molds, blow molds, low strain molds and rubber molds. With the development of the marketplace, awesome-hard aluminum has changed metallic within the marketplace as the principle material for mould processing. Mold aluminum has good sized benefits over die steel.

1, mild weight.The influence that the aluminium sheet offers humans is mild weight. It is true that the density of the aluminum plate is most effective 36% of that of the general steel mildew. Therefore, the inertia of the mold processed by using the aluminum plate is tremendously low, and the addition and deceleration are fairly smooth inside the production system, that could effectively reduce the lack of the mould, the advantage is enormous.

2, accurate corrosion resistanceIn the natural environment, the aluminium sheet plate has accurate corrosion resistance and oxidation resistance, specially the 5052 aluminum plate, the 6061 aluminium sheet, and the 7075 aluminum plate have been broadly used in mold production.

3, strong mechanical processingThe aluminum plate is straightforward to machine and has high dimensional stability. The reducing velocity of the aluminum plate is greater than 6 times quicker than that of the overall die metal, that can significantly lessen the mildew processing time and successfully provide the manufacturing velocity.

4, accurate thermal conductivityThe thermal conductivity of the aluminium sheet for mildew is higher than that of the general die steel, and the bloodless slicing time throughout the mold manufacturing can be saved via extra than 50%, and the manufacturing efficiency of the mold is substantially improved.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Jeux

- Gardening

- Health

- Domicile

- Literature

- Music

- Networking

- Autre

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness

- IT, Cloud, Software and Technology