Do You Know About Die Casting Technology?

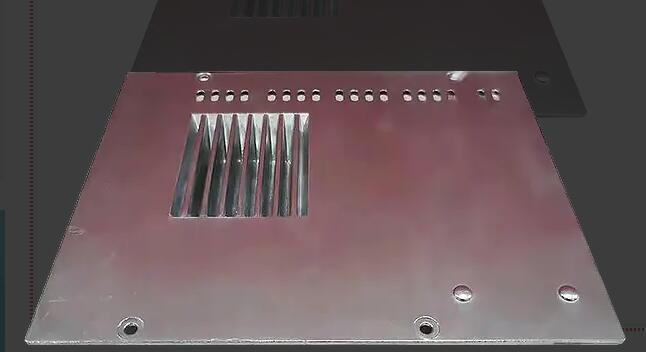

A die cast part is a metal casting that uses high pressure to force molten metal into a cavity formed by two dies. It shares characteristics with the plastic manufacturing process of injection molding.

In the larger field of metal casting, die casting is one of the most popular techniques due to its accuracy, high quality, and level of detail. The broader category of metal casting that has existed for thousands of years contains many different processes that use molds to form liquid metal. Historically, this process has often involved pouring liquid metal into a mold with the aid of gravity—many metal casting processes still work this way. However, die casting is a relatively new form of metal casting introduced in the 19th century that uses pressure rather than gravity to fill a mold cavity.

Die casting is sometimes called high pressure die casting because pressure (usually 10-140 MPa) is used to force the metal into the mold cavity. The associated process of low pressure die casting (LPDC) is less common. Die casting is generally divided into one of two categories: hot chamber die casting and cold chamber die casting, which is suitable for different types of metals. However, there are other, more niche types of die casting, such as semi-solid metal casting (SSM).

In simple terms, metal die casting works by using high pressure to force molten metal into a mold cavity, which is formed by two hardened steel molds. Once the cavity is filled, the molten metal cools and solidifies, and the mold opens so the part can be removed. In practice, however, the process has many steps and requires skilled engineers to operate the die casting equipment.

NingBo GSK Powder Metallurgy Co., Ltd. is a belt tensioner pulley factory, which manufactures MIM-Lock Case, powder metal pulley, etc. Welcome to inquire.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Spiele

- Gardening

- Health

- Startseite

- Literature

- Music

- Networking

- Andere

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness

- IT, Cloud, Software and Technology