The Power of Precision: HDPE Sheets in Engineering Excellence

High-density polyethylene (HDPE) sheets have become a cornerstone of modern engineering, offering a unique blend of versatility, durability, and cost-effectiveness. These robust plastic sheets find application across diverse industries, from construction and manufacturing to marine environments and chemical processing. Their ability to be precisely engineered for specific needs makes them a powerful tool for achieving engineering excellence.

Understanding HDPE Sheets

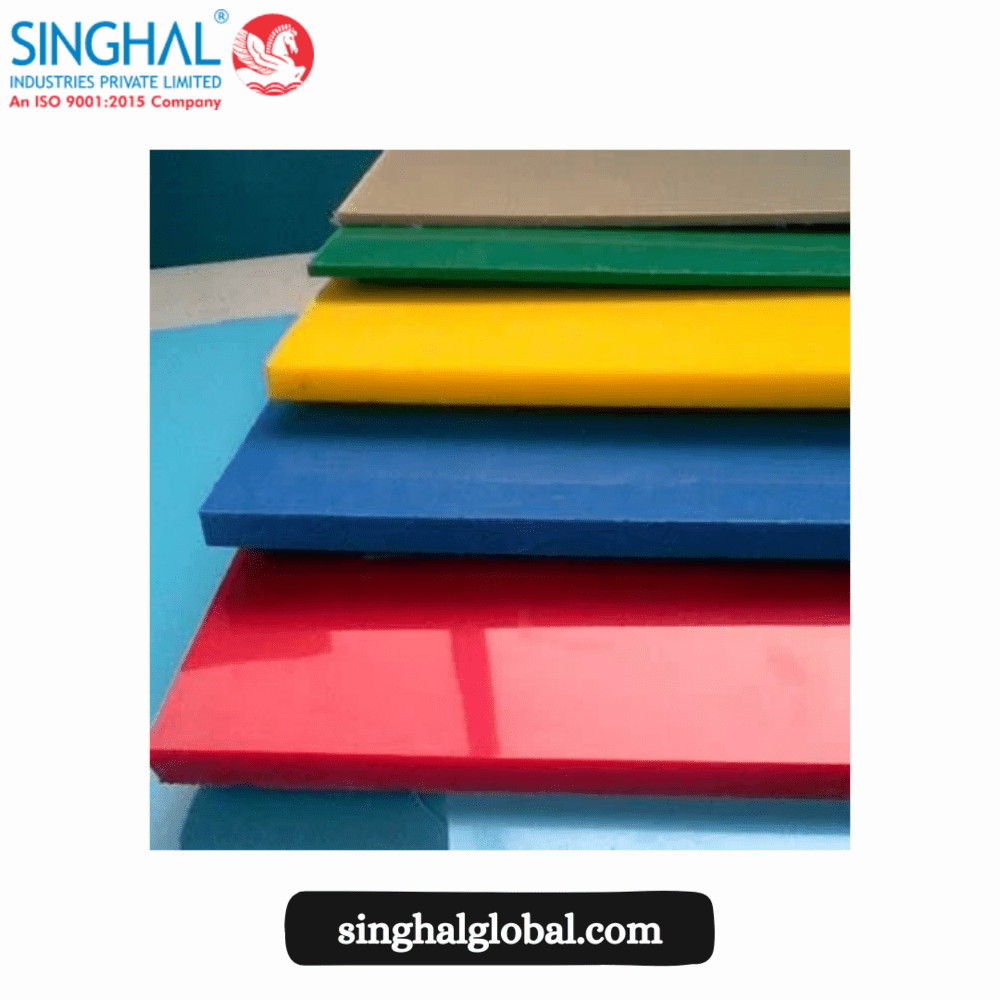

HDPE, a thermoplastic polymer, is known for its exceptional strength, rigidity, and chemical resistance. HDPE plastic sheets manufacturers create these sheets by extruding molten HDPE through a die, resulting in a uniform and consistent product. The sheets come in various thicknesses, sizes (including the popular 4x8 ft sheets), and even colors to cater to a wide range of applications.

The Power of Precision in HDPE Sheets

The true power of HDPE sheets lies in their ability to be precisely tailored for specific engineering needs. This precision manifests in several key ways:

1. Dimensional Accuracy: HDPE plastic sheets are manufactured with tight tolerances, ensuring consistent dimensions throughout the sheet. This allows engineers to design projects with a high degree of accuracy, minimizing the need for rework and maximizing efficiency.

2. Tailored Properties: Manufacturers can modify the properties of HDPE sheets through additives and processing techniques. For example, sheets can be made UV-resistant for outdoor applications, flame-retardant for safety purposes, or even conductive for electrical applications. This allows engineers to select the perfect sheet for their specific needs.

3. Fabrication Versatility: HDPE sheets are highly machinable. They can be easily cut, drilled, welded, and formed into complex shapes using conventional tools. This versatility empowers engineers to design intricate components and integrate them seamlessly into their projects.

Engineering Excellence with HDPE Sheets

The impact of HDPE sheets on various engineering disciplines is undeniable. Here are some prominent examples:

1. Construction: HDPE sheets find extensive use in construction projects due to their strength, weather resistance, and waterproofing properties. They are used as vapor barriers, concrete curing membranes, erosion control mats, and even for building foundations.

2. Manufacturing: Best HDPE sheets serve as durable work surfaces, machine guards, and noise dampening materials in manufacturing facilities. Their chemical resistance makes them ideal for use around paints, solvents, and other industrial chemicals.

3. Marine Applications: HDPE's superior resistance to saltwater corrosion makes it a valuable material for boat building, docks, and marine structures. Its lightweight nature also contributes to improved fuel efficiency in boats.

4. Chemical Processing: HDPE sheets offer excellent chemical resistance, making them ideal for lining tanks, pipes, and containment areas for storing and transporting corrosive chemicals. This ensures safety and prevents environmental contamination.

Beyond the Benefits: Considerations for Using HDPE Sheets

While HDPE sheets offer numerous advantages, it's essential to consider some factors for optimal use:

1. Temperature Limitations: HDPE has a maximum service temperature limit. Exceeding this limit can lead to softening and deformation. Engineers must ensure the operating temperatures remain within the recommended range for the specific HDPE grade.

2. Environmental Impact: Like all plastics, HDPE sheets have an environmental impact. While they are often recyclable, responsible disposal practices are crucial. Choosing recycled HDPE sheets can further minimize the environmental footprint.

3. UV Degradation: Standard HDPE sheets can degrade under prolonged exposure to UV radiation. For outdoor applications, using UV-stabilized HDPE sheets is essential to ensure longevity.

Conclusion

HDPE sheets are a powerful tool in the hands of skilled engineers. Their versatility, durability, and ability to be precisely tailored for specific needs make them a driving force behind engineering excellence across diverse industries. As technology advancements continue, the applications of HDPE sheets are likely to expand even further, shaping the future of engineering with precision and efficiency.

FAQs (Frequently asked questions)

Q1. What are the different types of HDPE plastic sheets available?

A1. HDPE sheets come in various thicknesses, sizes, and colors. Additionally, manufacturers offer sheets with specific properties like UV resistance, flame retardancy, and conductivity.

Q2. Where can I find HDPE plastic sheet manufacturers?

A2. A simple online search for "HDPE plastic sheet manufacturers" will provide you with a list of reputable suppliers in your area.

Q3. How do I choose the right size and thickness of HDPE sheets for my project?

A3. The ideal size and thickness will depend on the specific application. Consider factors like load-bearing requirements, forming needs, and desired rigidity when making your selection. Consulting with an HDPE supplier or engineer is recommended for complex projects.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Spiele

- Gardening

- Health

- Startseite

- Literature

- Music

- Networking

- Andere

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness

- IT, Cloud, Software and Technology