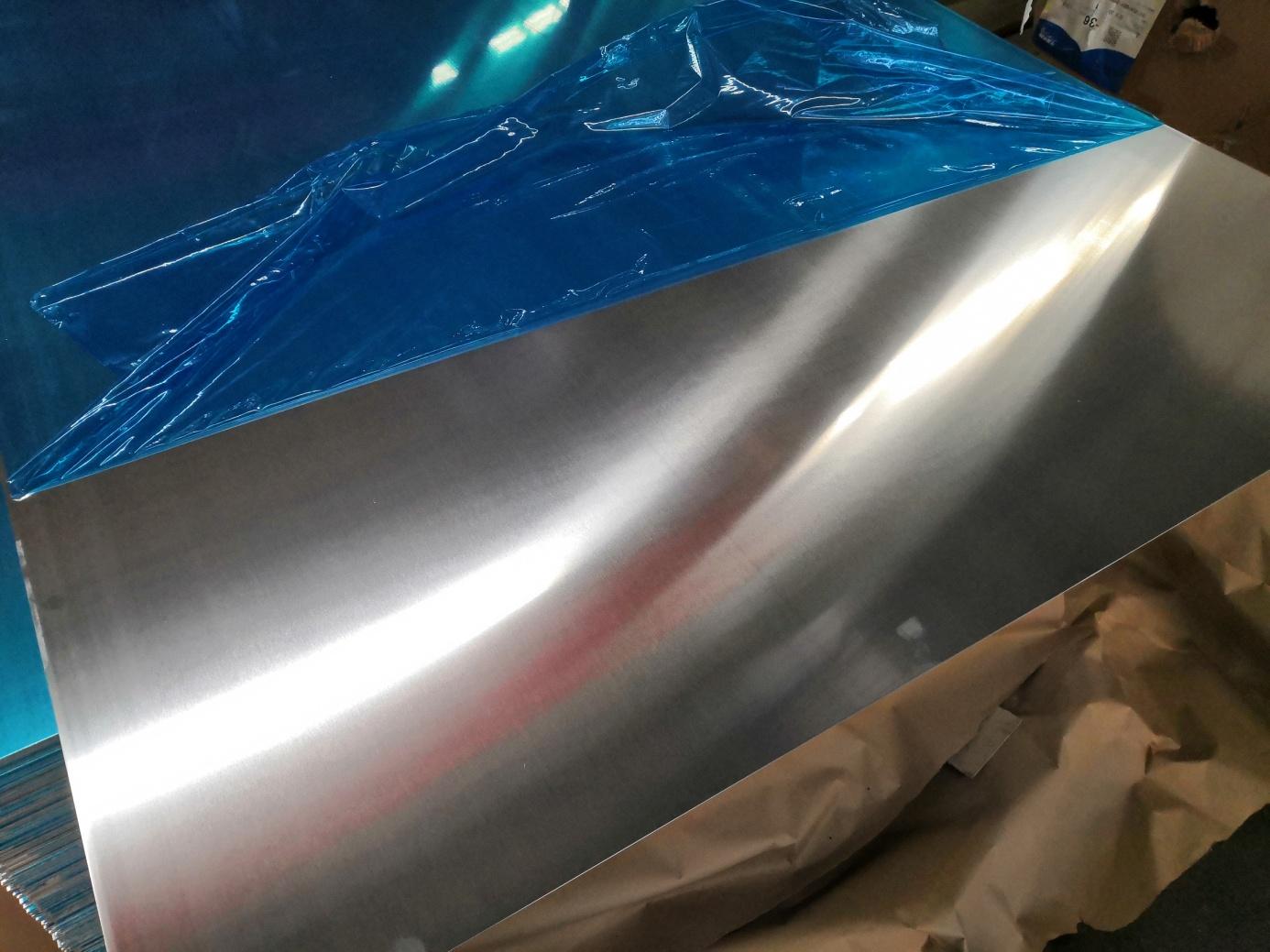

Aluminium sheets for aircraft 7075

The aircraft enterprise is regard as the most advanced industry, and the necessities on the aircraft element is very strict. The 7075 and 7005 are the maximum not unusual use aluminum alloy in aluminium sheets for aircraft. These days our topic is 7075 aluminium sheet, 7075 is an aluminum alloy with zinc as the principle alloying detail, however every so often a small amount of magnesium and copper are added. Among them, outstanding-tough aluminum alloy consists of lead, zinc, magnesium and copper alloy, the hardness is close to the steel and can be heat treatment. 7075 aluminium sheet is a high-power warmness-treatable alloy with exact corrosion resistance and exact mechanical houses.

As an ordinary plane aluminium sheet, 7075 aluminum sheet is a cold-dealt with forging alloy with excessive power and high hardness, a ways better than slight metal. 7075 aluminum sheet plate is one of the maximum powerful industrial alloys, with commonplace corrosion resistance, right mechanical houses and anode reaction. The exceptional grain makes the deep drilling overall performance better, the tool put on resistance is superior, the thread rolling is different from the weight, and the favored metallic material with decrease density necessities and higher hardness necessities. 7075 aluminum plate is generally used to fabricate plane systems and other high-strain structural elements that require high energy and high corrosion resistance, such as plane higher and decrease wing panels, purlins and partitions on plane. The aluminium sheets for aircraft 7075 has properly solution after answer treatment, top warmness treatment strengthening impact, excessive strength underneath a hundred and fifty °C, properly low temperature power, negative welding overall performance, stress corrosion cracking tendency, double-degree getting older can enhance anti-SCC overall performance.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Juegos

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness

- IT, Cloud, Software and Technology