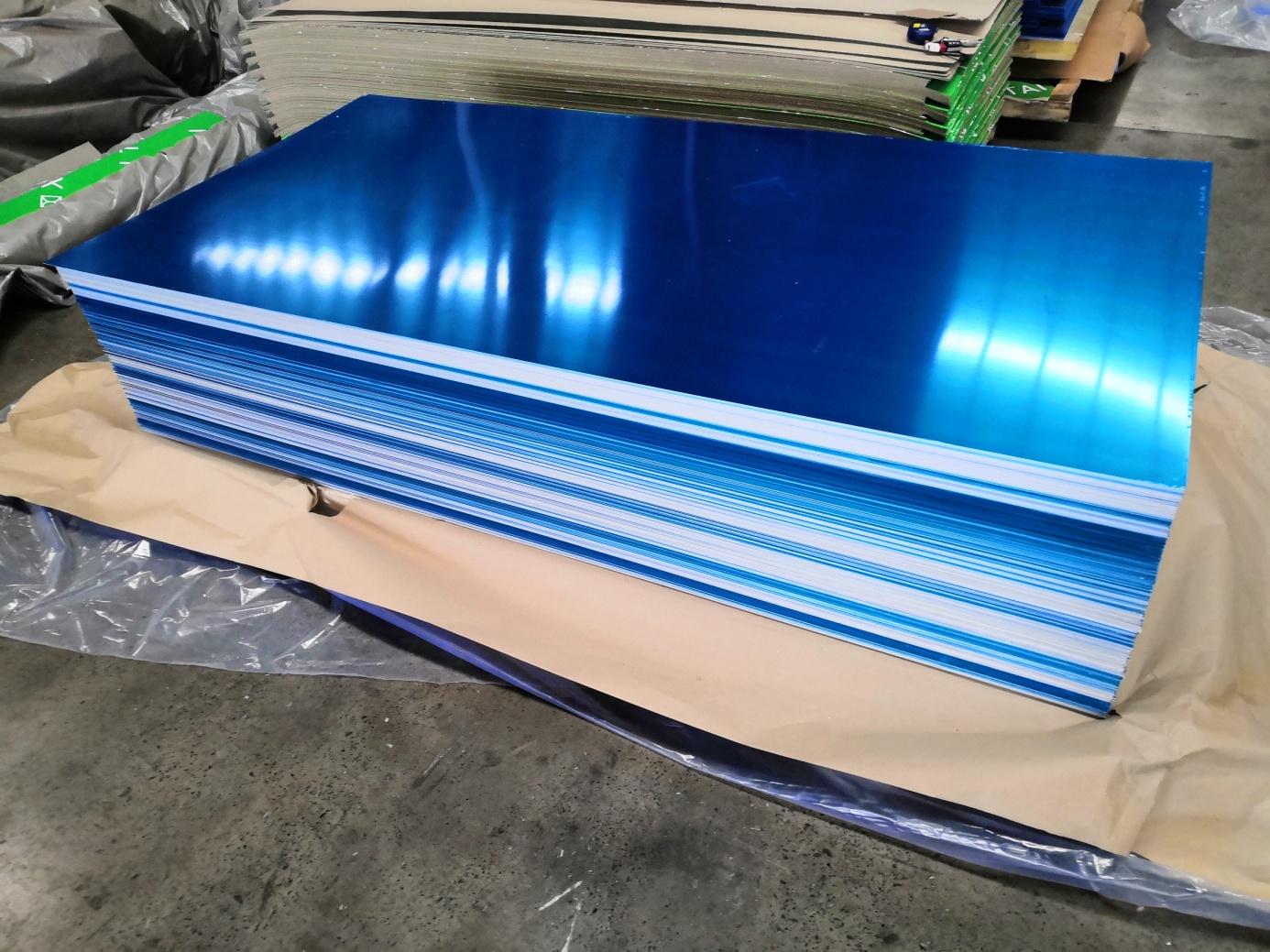

Marine Grade Aluminium Plates 5083 h111

Marine grade aluminium plates 5083 h111 has fantastic corrosion resistance and weldability, coupled with excessive electricity, this alloy is specially designed for welded systems requiring most weld energy and performance. The magnesium alloy of 5083 marine grade aluminum plate is usually around 4%-four.Five%, which belongs to the series with notably high magnesium alloy content material inside the 5000 series aluminum plate. Magnesium alloy can provide hardness. Typically, the higher the magnesium alloy content, the better the hardness of the aluminum plate. The hardness of the 5083 aluminum plate is close to that of the 6061 aluminum plate.

Marine grade 5083 aluminium sheet plate h111 is an average magnesium-aluminum-silicon alloy with excessive corrosion resistance and rust resistance. The underwater a part of the ship, mainly in the perennial seawater touch, the underwater a part of the hull have to be capable of face up to the corrosion of seawater for a long time. And those merchandise often use 5083 H111, 5083H116 and 5083H321, H116 and H321 of 5083 marine grade aluminum plate have right corrosion resistance and are greater appropriate for the underwater environment of the ocean than H111 and H112. Although the temperature of 5083 H116 aluminum plate and 5083 H321 marine grade aluminum plate is simplest barely exceptional in the production system, the corrosion resistance is obviously better than other states. The marine grade aluminum plate supplied by HUAWEI Aluminum have benefit CSS DNV LR ABS BV certification, which make sure the product best for shipbuilding.

The marine grade aluminium plates 5083 h111 can be purchased from HUAWEI Aluminum, and different tempers are also on sale. According to CCS "Code for substances and Welding":

1, H111:

Aluminum alloy with magnesium content no longer less than three.0%, it's miles suitable for merchandise with sufficient paintings hardening beneath the situation that the very last annealing does no longer meet the necessities of the annealed state, but the diploma of work hardening isn't absolutely consistent with the HX1 nation;

2, H112:

Aluminum alloy with magnesium content material no longer much less than 3.0%, it is appropriate for products that achieve positive characteristics for the duration of thermal processing, and such merchandise have mechanical houses necessities.

3, H116:

Aluminum alloy with magnesium content material now not less than 3.Zero%, inside the kingdom after anti-corrosion remedy;

Four, H321:

The country of aluminum alloy with magnesium content material now not much less than 3.Zero% after work hardening and stabilization remedy.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Jogos

- Gardening

- Health

- Início

- Literature

- Music

- Networking

- Outro

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness

- IT, Cloud, Software and Technology