Rice Mills in India: A Comprehensive Guide to the Industry

Rice is a staple food for a large part of the world's population, particularly in Asia where it is a dietary staple. India, being one of the largest producers and consumers of rice, plays a significant role in the global rice market. Rice mills in India are crucial in the processing and distribution of rice, ensuring its availability and quality for consumers worldwide. In this article, we delve into the intricacies of the rice mill industry in India, exploring its history, processes, challenges, and future prospects.

History of Rice Mills in India

Rice milling in India has a long history, dating back to ancient times. The traditional method of pounding rice to remove the husk was labor-intensive and time-consuming. However, with technological advancements, modern rice mills have revolutionized the industry, making the process more efficient and cost-effective.

Types of Rice Mills in India

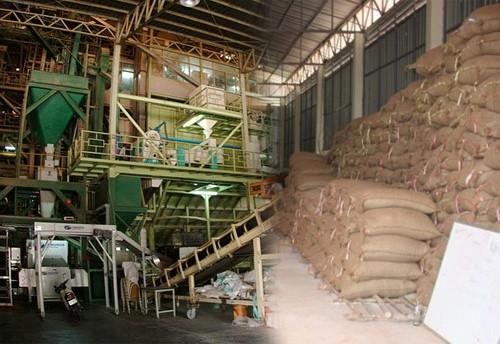

There are two main types of rice mills in India: huller mills and modern rice mills. Huller mills are traditional mills that use a simple process to remove the husk from rice. Modern rice mills, on the other hand, employ advanced technology to produce high-quality rice efficiently.

Process of Rice Milling

The process of rice milling involves several stages, each essential in ensuring the quality of the final product. These stages include cleaning, husking, paddy separation, milling, polishing, and grading. Modern rice mills use machinery such as pre-cleaners, de-stoners, huskers, polishers, and graders to automate these processes, resulting in higher efficiency and better quality rice.

Challenges Faced by Rice Mills in India

Despite the technological advancements in the industry, rice mills in India face several challenges. These include power shortages, inadequate infrastructure, lack of modernization, and competition from unorganized sectors. Additionally, environmental concerns regarding the disposal of rice husk and other by-products pose challenges to the sustainability of rice mills.

Future Prospects of Rice Mills in India

The future of rice mills in India looks promising, with increasing demand for rice both domestically and internationally. Technological advancements, government support, and initiatives such as the establishment of rice technology parks are expected to further boost the growth of the industry. Additionally, the focus on sustainable practices and value addition is likely to drive innovation in the sector.

Conclusion

Rice mills play a crucial role in the Indian agriculture and food processing industry. With the right mix of technology, innovation, and sustainable practices, the industry is poised for significant growth in the coming years. By understanding the history, processes, challenges, and future prospects of rice mills in India, we can appreciate the importance of this industry in the global rice market.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Games

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness

- IT, Cloud, Software and Technology