Wood Plastic Composite: An Innovative Material for Sustainable Future

Composition and Manufacturing of WPC

The main components of WPC are wood or other organic fillers and polymer binders. Wood fibers or flour usually constitute about 60-80% of the total volume of WPC. Common thermoplastic binders used include polyvinyl chloride (PVC), polyethylene, polypropylene, and polyurethane. These thermoplastics act as matrix that holds the wood fibers together.

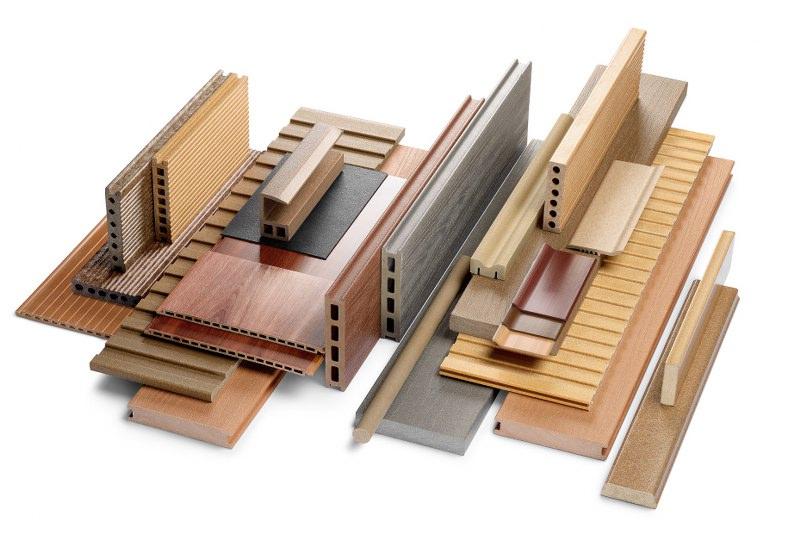

WPC is produced through an extrusion process. In this process, the dried and sized wood fibers are first blended with polymer pellets in an extruder. The temperature inside the extruder is raised above the melting point of thermoplastic, which allow the plastic to flow and coat each wood fiber. The blended material is then extruded and formed into different profiles like boards, rails or decking boards through die face. The final product is then air cooled to complete its shape.

Properties and Applications of Wood plastic composite

Some key properties of WPC that make it attractive for different applications include:

Durability: WPC can withstand impact, warping, splitting, cracking and rotting more effectively than plain wood. It offers long product life even under harsh weather conditions.

Rust and Corrosion Resistance: Unlike metals, Wood Plastic Composite does not rust or corrode even after prolonged exposure to moisture and chemicals.

Low Maintenance: WPC does not require paints, stains or other treatments for protection. It retains its finishes for years with minimal care.

Thermoplastic Binders Prevent cracking and splitting: The plastic in WPC fills cracks and crevices in wood fibers, protecting the materials from absorbing moisture.

Environment Friendly: WPC requires less energy in processing and produces lower greenhouse gas emissions compared to plastics. It also utilizes recycled plastic and wood waste.

Due to its properties, WPC finds application in external construction such as decking boards, railings, fencing, windows, and doors. It is also used for making indoor flooring, wall panels, furniture and non-structural construction applications. The automotive and marine sectors also use WPC for non-critical parts.

Get more insights on Wood Plastic Composite

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Spiele

- Gardening

- Health

- Startseite

- Literature

- Music

- Networking

- Andere

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness

- IT, Cloud, Software and Technology