Eco-Friendly Isobutene Market : A Game Changer in Green Fuel Additives

Overview

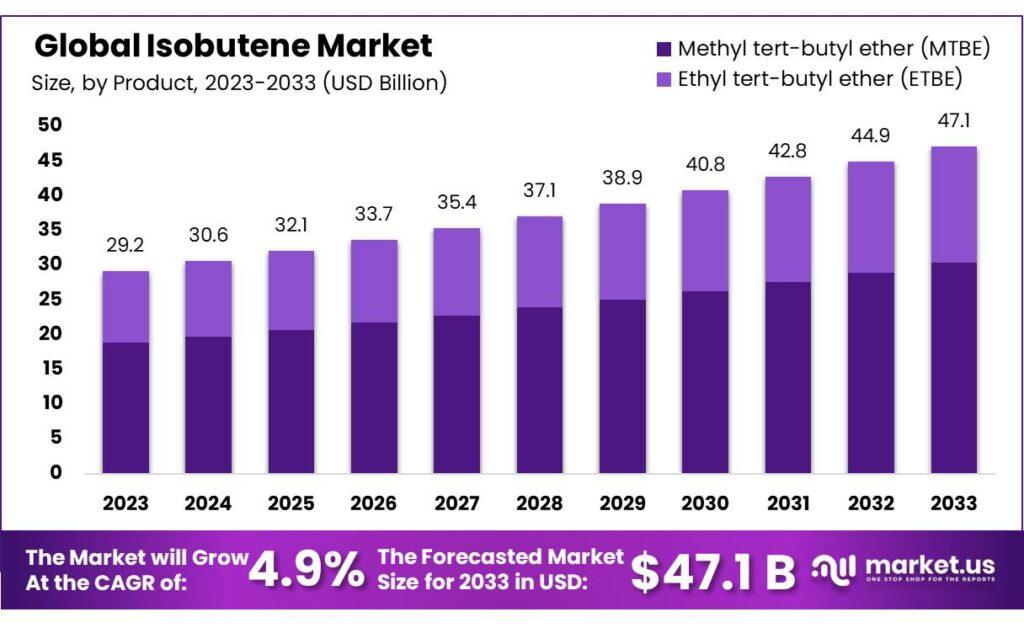

Isobutene Market size is expected to be worth around USD 47.1 billion by 2033, from USD 29.2 Bn in 2023, growing at a CAGR of 4.9% during the forecast period from 2023 to 2033.

The isobutene market refers to the global industry focused on the production, distribution, and sale of isobutene, a colorless gas with significant industrial applications. Isobutene, also known as isobutylene, is a crucial component in the manufacturing of various chemicals and materials, including butyl rubber and high-octane aviation fuels. It is derived primarily from the refining of crude oil and the cracking of natural gas.

This market is driven by the demand from various end-use sectors such as automotive, aerospace, and chemical industries. The automotive sector, in particular, utilizes isobutene in the production of synthetic rubber for tires and other components, underscoring its importance in the global supply chain. Additionally, the rise in aviation fuel consumption propels the market further.

Technological advancements in production processes and the development of bio-based isobutene are key trends influencing the market. These innovations aim to enhance efficiency, reduce environmental impact, and provide sustainable alternatives to traditional petroleum-based methods. Such advancements are vital for meeting stringent environmental regulations and consumer demand for greener products.

Geographically, the market spans North America, Europe, Asia-Pacific, and other regions, with Asia-Pacific leading due to rapid industrialization and urbanization. Major players in the market focus on strategic collaborations, expansions, and product innovations to maintain competitive edge and cater to diverse regional demands.

Key Market Segments

By Application

-

Methyl Tert-Butyl Ether

-

Ethyl Tert-Butyl Ether

By End-Use

-

Automotive

-

Pharmaceutical

-

Oil and Gas

-

Other Applications

Download a sample report in MINUTES@https://market.us/report/isobutene-market/request-sample/

In 2023, Methyl tert-butyl ether (MTBE) led the market, capturing over 57.5% of the share due to its cost-effectiveness and versatility in fuel additives, solvents, and chemical manufacturing. The automotive segment dominated the market, accounting for over 36.5%, reflecting a significant shift in consumer preferences towards automotive products and services.

Маrkеt Кеу Рlауеrѕ

-

Evonik

-

ExxonMobil

-

ABI Chemicals

-

Global Bioenergies

-

Syngip BV

-

LanzaTech

-

Honeywell International

-

LyondellBasell Industries

-

Other Key Players

Drivers: The isobutene market is propelled by increasing demand for synthetic rubber, essential for products requiring exceptional gas and moisture impermeability, like tire components and gloves. The rise of eco-friendly bio-based isobutene, derived from plant glucose, is also a significant driver, offering a sustainable alternative to conventional gasoline additives. Industry collaborations and innovations, such as sustainable aviation fuel initiatives, further fuel market growth.

Restraints: The market faces challenges from price volatility linked to crude oil prices and stringent environmental regulations due to isobutene's hazardous nature. Compliance with these regulations adds operational complexities and costs. Additionally, the high cost of separating ethanol from water during bio-based isobutene production impacts its market competitiveness, posing a restraint on market expansion.

Opportunities: Opportunities in the isobutene market include the growing demand for sustainable fuel solutions, with bio-based isobutene poised as a green alternative. Advancements in technology and research enable innovative applications across various industries, such as pharmaceuticals and specialty chemicals. Strategic collaborations can foster innovation and market growth, while increasing awareness of eco-friendly practices drives demand for isobutene-derived products.

Challenges: The isobutene market must navigate price volatility due to its crude oil dependency and strict environmental regulations. The cost of bio-based isobutene production, particularly ethanol separation, also poses a challenge. Overcoming these issues requires innovative manufacturing approaches, technological advancements, and proactive environmental compliance strategies to ensure sustainable market growth.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Spellen

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness

- IT, Cloud, Software and Technology