Polyester Geogrid: Reinforcing Soil Stability and Enhancing Infrastructure Durability

Polyester geogrid is a high-performance, cost-effective geosynthetic material used extensively in civil engineering and construction projects to enhance soil stability, provide reinforcement, and prevent erosion. With the rise in infrastructure developments worldwide, Polyester Geogrid for Road Construction have gained recognition for their durability, flexibility, and ability to extend the lifespan of roads, railways, retaining walls, and other structures.

This article explores everything you need to know about polyester geogrids, including their advantages, common uses, types, and answers to frequently asked questions (FAQs).

What is Polyester Geogrid?

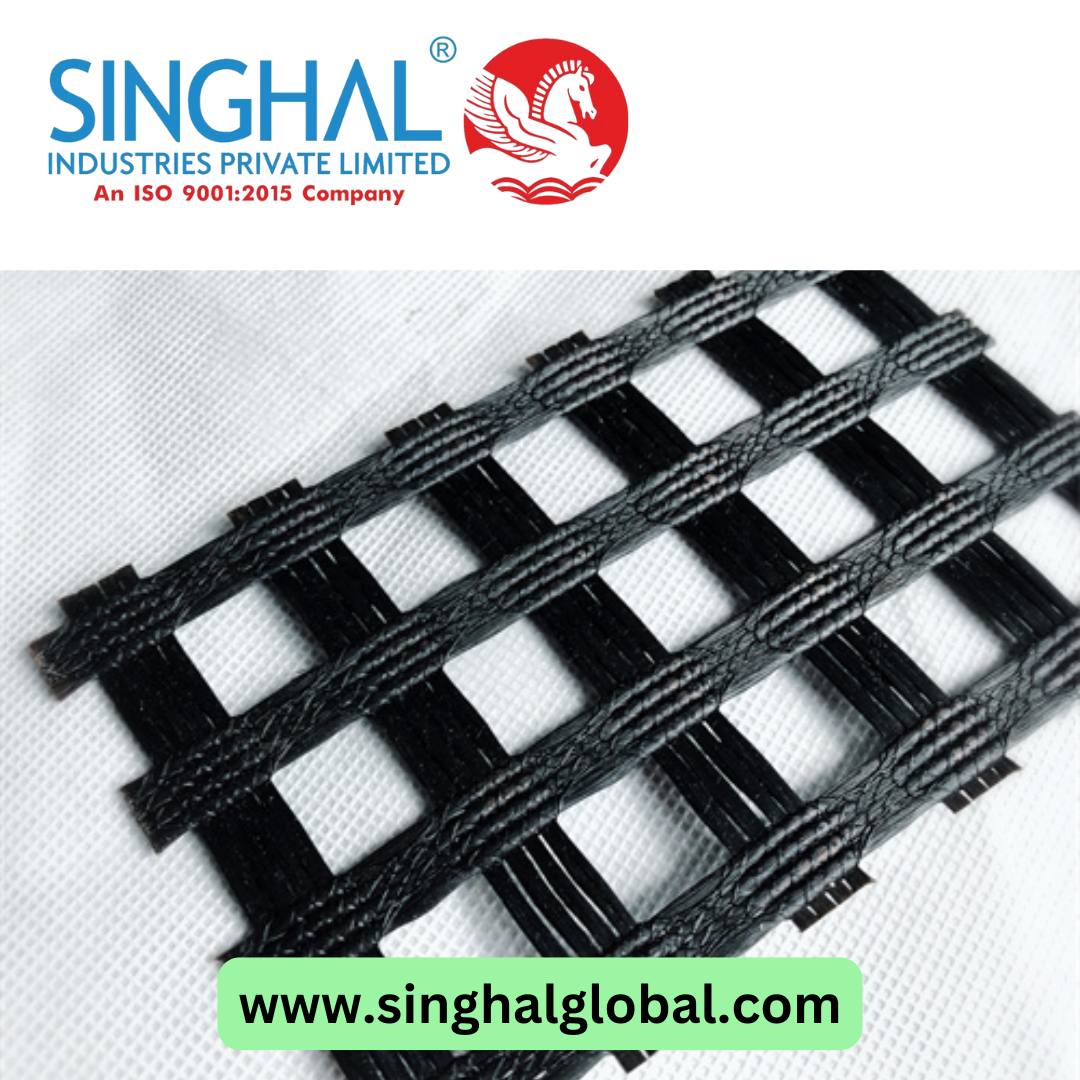

Polyester geogrid is a synthetic grid-like material made from high-tensile polyester fibers. These fibers are coated with PVC or other polymers to enhance resistance to chemicals, UV rays, and mechanical wear. Polyester geogrids are designed to provide soil reinforcement, distribute loads, and enhance the structural integrity of various construction projects.

The primary function of a polyester geogrid is to interlock with the soil or aggregate, forming a stable foundation. This interaction improves the load-bearing capacity of soils, making them more suitable for supporting heavy structures like roads, embankments, and retaining walls.

Benefits of Polyester Geogrid

Polyester geogrids offer several significant benefits that make them a preferred choice for civil engineering projects. Below are some of the key advantages:

1. High Tensile Strength

Polyester geogrids possess exceptional tensile strength, which means they can withstand heavy loads and distribute them evenly across the soil. This helps prevent ground deformation and improves the overall stability of the construction.

2. Cost-Effective Solution

When used in construction, polyester geogrids reduce the amount of fill material needed, lowering costs for projects. By reinforcing the soil, the grid decreases the need for frequent maintenance and repairs, resulting in long-term savings.

3. Durability and Longevity

Thanks to their high chemical resistance and UV protection, polyester geogrids are durable and capable of withstanding extreme environmental conditions. They do not degrade over time and have a long service life, which is vital for projects like highways and embankments.

4. Flexibility and Ease of Installation

Polyester geogrids are lightweight and flexible, making them easy to handle and install. Their versatility allows them to be used in a wide range of applications, including slopes, roads, railways, and retaining walls.

5. Erosion Control

In addition to providing soil reinforcement, polyester geogrids help control erosion by stabilizing the soil. This is particularly beneficial in areas where heavy rains or floods could otherwise wash away the soil, potentially compromising the stability of structures.

6. Sustainability

The use of polyester geogrids supports sustainable construction practices. By reinforcing weak soils, geogrids minimize the need for additional resources like concrete and asphalt, helping reduce the environmental impact of large-scale construction projects.

Common Applications of Polyester Geogrid

Polyester geogrids are used in a wide variety of construction and civil engineering projects. Below are some of the most common applications:

1. Road Construction

One of the most common uses of polyester geogrids is in road construction. Geogrids are placed beneath the asphalt or concrete layers to provide soil reinforcement, enhance load distribution, and prevent the formation of potholes and cracks. This reinforcement increases the lifespan of roads and reduces the need for frequent repairs.

2. Railway Construction

In railway projects, polyester geogrids help stabilize the tracks by reinforcing the ballast and subgrade layers. By providing structural support, the geogrids ensure that the railway tracks remain stable and can handle heavy loads and vibrations from passing trains.

3. Retaining Walls and Slopes

Retaining walls and steep slopes require additional reinforcement to maintain stability and prevent erosion. Polyester geogrids are used to stabilize these structures by interlocking with the soil and providing resistance against lateral pressure. This reduces the risk of wall collapse or slope failure.

4. Embankments

When building embankments, especially over weak or unstable soils, polyester geogrids provide much-needed support and reinforcement. They help distribute loads evenly, prevent settlement, and ensure that the embankment remains stable over time.

5. Landfill Projects

In landfill projects, polyester geogrids are used to reinforce the soil layers and prevent settlement. They also help control erosion and ensure that the landfill structure maintains its integrity over the long term.

6. Erosion Control

Polyester geogrids are effective at preventing erosion on slopes, embankments, and riverbanks. By reinforcing the soil and providing stability, the geogrids help protect against soil displacement caused by water or wind.

Types of Polyester Geogrids

There are two main types of Polyester Geogrid Reinforcement based on their construction and function:

1. Uniaxial Polyester Geogrid

Uniaxial geogrids are designed to provide high tensile strength in one direction. They are typically used in applications where reinforcement is required along a single axis, such as in retaining walls and embankments. These grids help resist lateral soil movement and provide stability.

2. Biaxial Polyester Geogrid

Biaxial geogrids offer high tensile strength in two perpendicular directions. This makes them suitable for applications where reinforcement is needed in both the longitudinal and transverse directions, such as in road and railway construction. Biaxial geogrids enhance load distribution and provide overall soil stability.

How to Install Polyester Geogrid

Installing polyester geogrid requires attention to detail to ensure optimal performance. Below are general steps for installation:

1. Site Preparation

Clear the site of debris, rocks, and vegetation. Make sure the ground is level and compacted.

2. Unroll the Geogrid

Lay the geogrid over the prepared surface. If necessary, overlap adjacent sections by at least 12 inches to prevent gaps. Ensure the geogrid is aligned properly with the intended reinforcement direction (uniaxial or biaxial).

3. Secure the Geogrid

Anchor the geogrid in place using pins, stakes, or heavy weights. This ensures that the geogrid stays in position during the next phases of construction.

4. Add Fill Material

Once the geogrid is securely in place, cover it with the appropriate fill material, such as soil, gravel, or ballast. Spread the material evenly and compact it to ensure proper load distribution.

5. Repeat as Necessary

In projects with multiple layers, repeat the process until the desired level of reinforcement is achieved.

Conclusion

Polyester geogrids have revolutionized the construction and civil engineering industries by providing an effective solution for soil reinforcement and stability. Their high tensile strength, durability, and flexibility make them ideal for a variety of applications, from road construction to erosion control. By understanding the different types of Polyester Geogrid Installation, their benefits, and proper installation techniques, you can ensure that your project remains structurally sound and environmentally sustainable for years to come.

Frequently Asked Questions (FAQs)

1. What is the primary purpose of polyester geogrid?

The primary purpose of polyester geogrid is to provide soil reinforcement, improve load distribution, and enhance the stability of structures such as roads, retaining walls, and embankments.

2. How long does polyester geogrid last?

Polyester geogrids are highly durable and can last for decades, depending on environmental conditions and the specific application. With proper installation and maintenance, polyester geogrids can have a lifespan of 50 years or more.

3. Can polyester geogrids be used in extreme weather conditions?

Yes, polyester geogrids are designed to withstand extreme weather conditions. They are resistant to UV rays, chemicals, and moisture, making them suitable for use in harsh climates.

4. What are the key differences between uniaxial and biaxial geogrids?

Uniaxial geogrids provide strength in one direction and are typically used in retaining walls and embankments. Biaxial geogrids provide strength in two perpendicular directions and are ideal for road and railway construction.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Games

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness

- IT, Cloud, Software and Technology