Automotive Robotics Market Set for Explosive Growth as Innovation and Demand Drive Technological Advancements

The Automotive Robotics Market Growth is experiencing a period of transformative growth, driven by rapid technological advancements and increasing demand for automation in the automotive industry. As automakers seek to enhance production efficiency, improve quality, and reduce operational costs, the adoption of robotics technology has become essential.

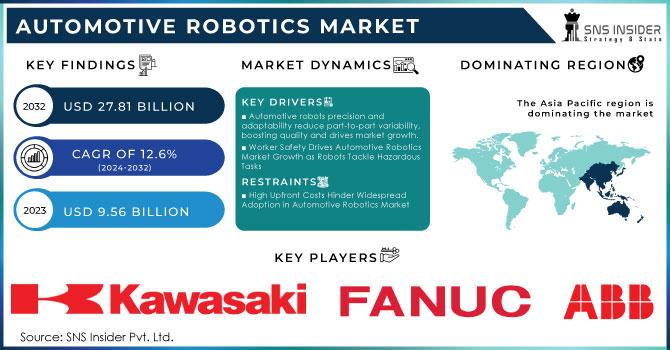

The global automotive robotics market, valued at approximately USD 9.56 billion in 2023, is projected to grow at a robust compound annual growth rate (CAGR) of 12.6% through 2032. This growth is fuelled by innovations in robotics technology, evolving industry needs, and the drive towards more efficient and flexible manufacturing processes.

Get a Free Pdf Sample of Automotive Robotics Market Growth @ https://www.snsinsider.com/sample-request/1027

Major Players:

· FANUC Corporation (Japan)

· Kawasaki Heavy Industries

· Yaskawa Electric Corporation (Japan)

· KUKA AG (Germany)

· ABB (Switzerland)

· Comau

· DENSO WAVE INCORPORATED

· NACHI-FUJIKOSHI CORP.

· Rockwell Automation, Inc.

· Seiko Epson Corporation

Segments Analysis:

The automotive robotics market is segmented by type and application, each segment contributing to the overall market dynamics and growth trajectory.

1. by Type:

· Articulated Robots: Articulated robots, known for their flexibility and range of motion, are widely used in automotive manufacturing. Their versatility allows them to perform a variety of tasks, including welding, painting, and assembly. The demand for articulated robots is driven by their ability to handle complex and precise operations, making them a key component in modern automotive production lines.

· Cartesian Robots: Cartesian robots, or gantry robots, are characterized by their linear movement along X, Y, and Z axes. These robots are ideal for tasks that require precise and repetitive movements, such as material handling and assembly. The growing need for accurate and efficient handling of automotive components is driving the adoption of Cartesian robots.

· Cylindrical Robots: Cylindrical robots, with their cylindrical coordinate system, are commonly used for applications requiring vertical and rotational movement. They are particularly useful in material handling and assembly tasks, where their ability to handle heavy loads and reach different points in a cylindrical range is advantageous.

· SCARA Robots: SCARA (Selective Compliance Assembly Robot Arm) robots are known for their speed and precision in horizontal movements. They are widely used in applications such as assembly, packaging, and material handling. The increasing demand for high-speed and accurate assembly processes in automotive manufacturing is driving the adoption of SCARA robots.

· Others: This category includes various specialized robots designed for specific applications within the automotive industry. These robots may offer unique capabilities and are often customized to meet particular manufacturing needs.

2. by Application:

· Welding: Welding robots are extensively used in automotive manufacturing to perform precise and repetitive welding tasks. Their ability to ensure high-quality welds and maintain consistent production standards makes them essential in the production of automotive components and assemblies.

· Painting: Painting robots are employed to apply coatings and finishes to automotive parts and bodies. These robots enhance the quality of paint application, reduce waste, and improve safety by minimizing human exposure to hazardous chemicals.

· Material Handling: Material handling robots are used to move, sort, and manage automotive components throughout the production process. Their efficiency in handling and transferring materials contributes to streamlined operations and reduced production downtime.

· Assembly/Disassembly: Robots used for assembly and disassembly tasks help in the precise and efficient assembly of automotive parts. They improve production speed and accuracy while reducing the need for manual labour in complex assembly processes.

· Others: This category encompasses various other applications where robotics technology is used to enhance automotive manufacturing processes. These applications may include inspection, testing, and specialized operations tailored to specific industry requirements.

Regional Overview:

The automotive robotics market exhibits diverse trends across different regions, reflecting varying levels of technological adoption, industry demand, and economic conditions.

· North America: The North American market is a major hub for automotive robotics, driven by strong automotive manufacturing capabilities and significant investments in automation technology. The United States, in particular, is at the forefront of adopting advanced robotics solutions, supported by a well-established automotive industry and a focus on technological innovation.

· Europe: Europe is another key market for automotive robotics, characterized by a high concentration of automotive manufacturers and a strong emphasis on precision and quality. European countries are rapidly adopting robotics technology to enhance manufacturing efficiency and meet stringent quality standards.

· Asia-Pacific: The Asia-Pacific region is experiencing the fastest growth in the automotive robotics market, driven by the expanding automotive industry in countries like China, Japan, and South Korea. The region's focus on increasing production capacity and improving manufacturing processes is fuelling the demand for advanced robotics solutions.

· Latin America and Middle East & Africa: These regions are gradually increasing their adoption of automotive robotics, supported by growing automotive industries and expanding manufacturing capabilities. Market growth in these regions is driven by the need for improved production efficiency and competitiveness in the global automotive market.

Recent Trends:

· Technological Advancements: Innovations in robotics technology, including improvements in artificial intelligence, machine learning, and sensor integration, are enhancing the capabilities of automotive robots. These advancements are enabling more flexible, precise, and efficient manufacturing processes.

· Industry 4.0 Integration: The integration of robotics technology with Industry 4.0 concepts, such as IoT and data analytics, is transforming automotive manufacturing. Smart factories equipped with advanced robotics and connectivity are driving increased productivity and operational efficiency.

· Customization and Flexibility: There is a growing trend towards customizing robotics solutions to meet specific manufacturing needs. Flexible and adaptable robots are being developed to handle a wider range of tasks and accommodate changing production requirements.

· Sustainability Focus: The automotive industry is increasingly focusing on sustainability and reducing environmental impact. Robotics technology is playing a key role in optimizing manufacturing processes, reducing waste, and improving energy efficiency.

Conclusion:

The automotive robotics market is set for significant growth, driven by technological advancements, evolving industry needs, and increasing demand for automation. As the automotive industry continues to embrace robotics technology, the market for automotive robots is expected to expand, offering opportunities for innovation and efficiency. Stakeholders are encouraged to stay informed about emerging trends and advancements in robotics to capitalize on the growth potential of this dynamic market.

Read Full Details @ https://www.snsinsider.com/reports/automotive-robotics-market-1027

Contact Us:

Akash Anand – Head of Business Development & Strategy

info@snsinsider.com

Phone: +1-415-230-0044 (US) | +91-7798602273 (IND)

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Games

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness

- IT, Cloud, Software and Technology