Understanding Hollow Sheet Polycarbonate: A Versatile Solution for Various Applications

In the world of modern construction and design, material selection is paramount. One material that has gained significant popularity is the hollow sheet polycarbonate. This innovative product offers a unique combination of durability, lightweight properties, and excellent thermal insulation, making it an ideal choice for a wide range of applications. From roofing solutions to greenhouse construction, the versatility of hollow polycarbonate sheets is impressive. In this article, we will delve into the benefits, applications, and essential characteristics of PC hollow sheets.

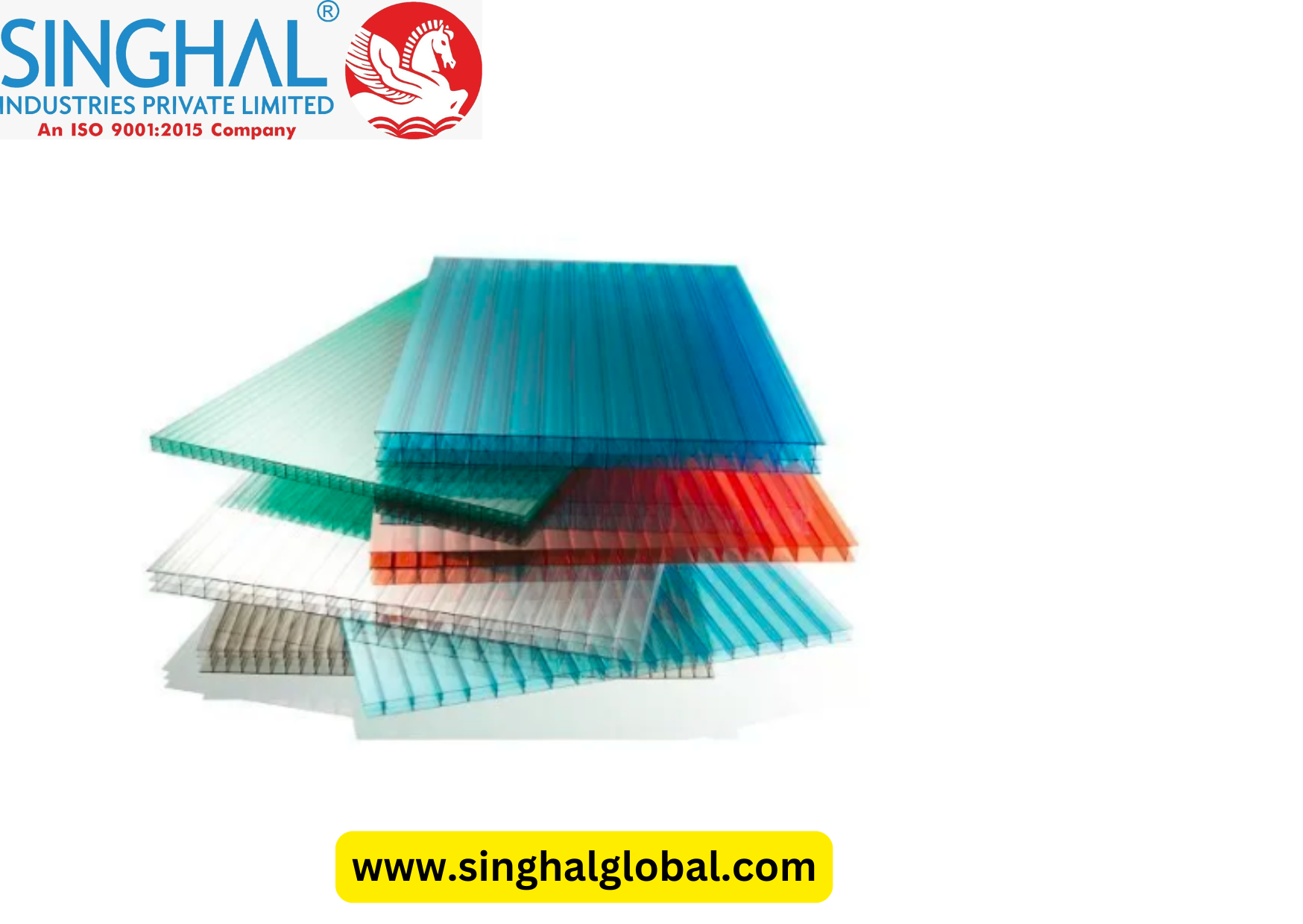

What is Hollow Sheet Polycarbonate?

Hollow sheet polycarbonate refers to a type of thermoplastic sheet made from polycarbonate resin, which features a hollow structure. This unique design consists of two or more layers of polycarbonate, forming air channels or pockets between them. These channels significantly enhance the material's insulation properties while keeping it lightweight. The combination of these attributes allows for optimal performance in various environments, from industrial applications to residential projects.

Benefits of Hollow Polycarbonate Sheets

-

Lightweight Yet Strong

One of the most notable features of hollow polycarbonate sheets is their exceptional strength-to-weight ratio. Despite being lightweight, polycarbonate is known for its high impact resistance, making it a safer alternative to glass. This strength is particularly beneficial in construction, where materials must withstand environmental stressors while being easy to handle and install. -

Excellent Insulation Properties

The hollow structure of these sheets creates air pockets that provide superior thermal insulation. This characteristic helps maintain stable temperatures within structures, reducing energy costs for heating and cooling. As a result, PC hollow sheets are an excellent choice for applications where temperature control is essential, such as greenhouses, skylights, and conservatories. -

UV Protection

Hollow sheet polycarbonate is often treated with UV-resistant coatings, protecting against harmful ultraviolet rays. This feature is particularly advantageous for outdoor applications, as it prevents yellowing and degradation over time. As a result, polycarbonate retains its clarity and strength, ensuring longevity in various environmental conditions. -

Versatility

The adaptability of hollow polycarbonate sheets is another significant advantage. They can be easily cut, shaped, and fabricated to suit various project requirements. Whether you need custom sizes for a specific installation or unique designs for aesthetic purposes, hollow polycarbonate sheets can be tailored to meet your needs. -

Cost-Effectiveness

While the initial cost of polycarbonate sheets may be higher than traditional materials like glass or acrylic, their long-term savings make them an economical choice. With minimal maintenance, enhanced durability, and energy efficiency, investing in PC hollow sheets often results in lower operational costs over time.

Applications of Hollow Polycarbonate Sheets

Given their numerous advantages, hollow sheet polycarbonate finds application across a wide array of industries:

-

Greenhouses

The agriculture sector frequently utilizes Hollow polycarbonate sheet in greenhouse construction. Their excellent insulation properties help maintain optimal growing conditions while allowing natural sunlight to penetrate, promoting plant growth. Additionally, the UV protection ensures that the internal environment remains stable, reducing the risk of plant stress. -

Roofing and Skylights

Due to their lightweight and durable nature, hollow polycarbonate sheets are ideal for roofing applications. They can be used for patio covers, carports, and skylights, allowing natural light while providing protection from the elements. Their insulating properties also contribute to energy efficiency in buildings. -

Partitions and Dividers

In commercial settings, PC hollow sheets are often used to create transparent partitions and dividers. They offer privacy while allowing light to flow through, making them an excellent choice for office environments, retail spaces, and healthcare facilities. -

Signage and Displays

The clarity and impact resistance of hollow sheet polycarbonate make it a popular choice for signage and display applications. It can withstand harsh weather conditions, ensuring that signs remain intact and legible, whether used outdoors or indoors. -

Protective Barriers

In environments where safety is a concern, such as factories or warehouses, polycarbonate sheets serve as effective protective barriers. Their strength helps prevent accidents while maintaining visibility in workspaces.

Key Considerations When Choosing Hollow Polycarbonate Sheets

When selecting hollow polycarbonate sheets for your project, consider the following factors:

-

Thickness: Different applications may require various thicknesses. Thicker sheets generally provide better insulation and impact resistance.

-

UV Protection: Ensure that the sheets you choose have a UV-resistant coating to prevent degradation and yellowing over time.

-

Customization: Depending on your project requirements, you may need sheets that can be customized in size or shape. Many manufacturers offer fabrication services to accommodate specific needs.

-

Manufacturer Reputation: Choosing a reputable manufacturer is crucial for ensuring product quality. Research and read reviews to find reliable sources of PC hollow sheets.

Conclusion

In conclusion, hollow sheet polycarbonate is a versatile and innovative material that offers numerous benefits for various applications. Its lightweight yet strong nature, excellent insulation properties, UV protection, and cost-effectiveness make it an ideal choice for builders, architects, and designers alike. Whether you’re constructing a greenhouse, designing a skylight, or seeking durable signage solutions, hollow polycarbonate sheets provide an effective and efficient solution.

Here Are Three Related For Hollow sheet polycarbonate

Q1: Are hollow polycarbonate sheets easy to install?

Ans. Yes, hollow polycarbonate sheets are lightweight and easy to handle, making them simple to install for various applications.

Q2: Can hollow polycarbonate sheets be cut to size?

Ans. Absolutely! PC hollow sheets can be easily cut to the desired size using standard tools, allowing for customization based on specific project requirements.

Q3: How long do hollow polycarbonate sheets last?

Ans. With proper care and maintenance, hollow sheet polycarbonate can last for many years, often exceeding 10-15 years, depending on the application and environmental conditions.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Spiele

- Gardening

- Health

- Startseite

- Literature

- Music

- Networking

- Andere

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness

- IT, Cloud, Software and Technology