How are the raw materials fed into the wet wipe making machine?

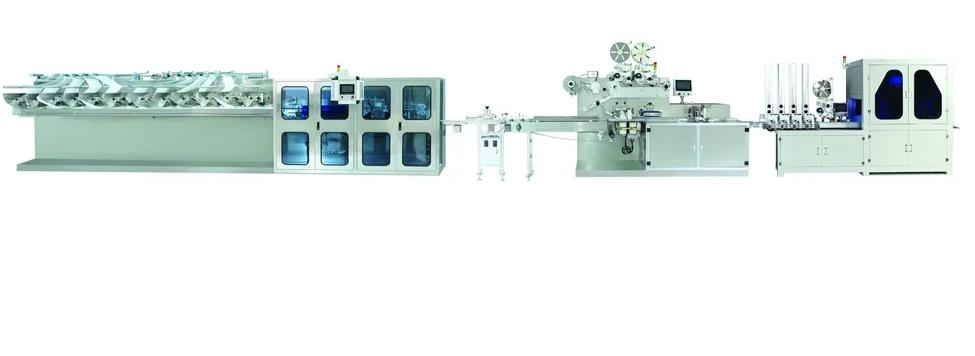

The feeding of raw materials into a China wet wipes packing machine supplier typically involves several steps:

-

Material Preparation: The primary raw materials include non-woven fabric, liquid solution (wetting agent), and any additional components like fragrances or preservatives. These materials are often pre-measured and prepared for the production process.

-

Non-Woven Fabric Roll Loading: The China wet wipe production line suppliers is supplied in large rolls. Operators load these rolls onto a feeding mechanism that unwinds the fabric as needed.

-

Liquid Solution Reservoir: The liquid solution is stored in a reservoir or tank. A pumping system is used to draw the solution from this reservoir and deliver it to the fabric.

-

Fabric Cutting: The unwound fabric is cut into the desired China wet wipes packing machine suppliers size using a cutting mechanism, which can be either a rotary cutter or a guillotine cutter.

-

Impregnation Process: The cut pieces of fabric are then passed through a soaking chamber where they are saturated with the liquid solution. This can be done using various methods such as spraying or dipping.

-

Wi

-

pe Folding and Packaging: Once saturated, the wipes are folded and stacked. Automated systems often handle this process, ensuring that the wipes are ready for packaging.

-

Quality Control: Throughout the process, quality control measures are implemented to ensure the consistency and quality of both the fabric and the liquid solution.

This automated process is designed to maximize efficiency and maintain hygiene standards, producing a consistent and high-quality product.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Games

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness

- IT, Cloud, Software and Technology