3D Sensors in Industrial Automation

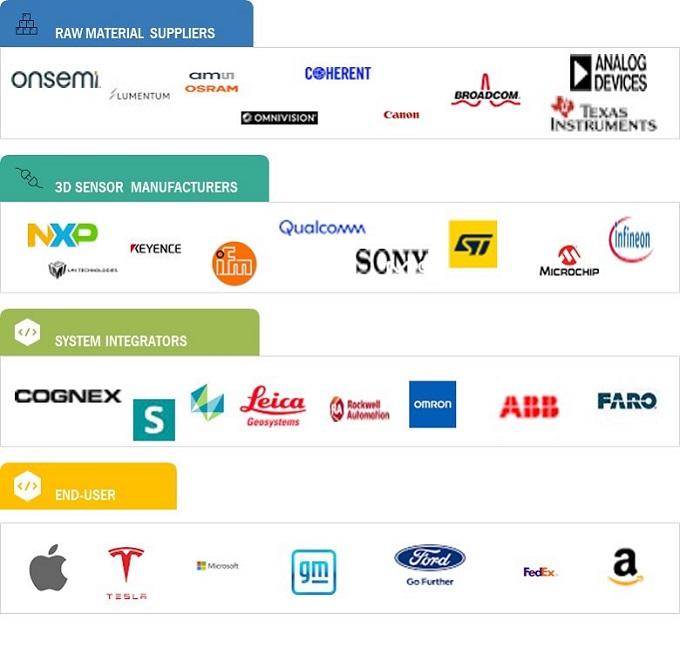

The industrial automation sector is increasingly adopting 3D sensors, driving the market's anticipated value of USD 12.8 billion by 2029. These sensors play a vital role in enhancing quality control, robotics, and machine vision, which are essential for improving operational efficiency and precision in manufacturing processes.

For example, 3D sensors are used in automated inspection systems to detect defects on production lines, significantly reducing waste and improving product quality. Robotics equipped with 3D sensors can perform complex tasks such as assembly, welding, and packaging with high accuracy.

Moreover, the integration of 3D sensing technology in supply chain management allows for real-time inventory tracking and management, further streamlining operations. As manufacturers continue to embrace Industry 4.0 principles, the demand for sophisticated 3D sensor solutions will continue to rise.

The use of 3D sensors also enhances predictive maintenance strategies. By continuously monitoring machinery and equipment, these sensors can detect anomalies that may indicate potential failures, allowing for timely interventions and reducing downtime. This proactive approach improves operational efficiency and reduces maintenance costs.

Download PDF Brochure @ https://www.marketsandmarkets.com/pdfdownloadNew.asp?id=248537071

In addition, the push for sustainability in industrial practices is driving the adoption of 3D sensors. By optimizing processes and minimizing waste, these technologies contribute to more environmentally friendly manufacturing, aligning with global sustainability goals. This trend underscores the importance of integrating advanced sensing technologies into future industrial applications.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Giochi

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Altre informazioni

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness

- IT, Cloud, Software and Technology