What Are The Screw Heads And How To Choose

The purpose of a screw’s design is to allow it to be removed and replaced without damaging the screw or the material it is connecting. Most are made of steel with a corrosion resistant coating, or stainless steel. Screws are available in an array of head shapes, threading, and custom features. Screw heads are classified under two broad categories — countersunk screw heads and non-counter sunk screw heads. The selection of a screw head should be determined by your scope of work and your preferred finish. Check out our KENENG screw heads to learn more.

Firstly, we introduce what are countersunk screw head and non-counter sunk screw heads

Countersunk Screw Heads

Countersunk screws mainly have oval, flat, or bugle heads. They sit flush on the surface of the material they are installed on and don’t protrude. This enables other objects to rest stably on the surface without being disturbed by the screw heads. Countersunk screws are often used in hard and soft woodwork businesss using a method referred to as countersinking. What this means is that you have to first drill a pilot hole with the correct head angle before installing the screw.

Depending on the type of screw head shape, countersinking will be necessary to ensure that your screws fit well on a surface. Some of the head shapes that will require countersinking include flat screw heads, raised screw heads, and bugle screw heads. For a flat screw head, you can also use a flat head screw cover to conceal the head. Luckily, a custom screw manufacturer has custom screw options that can be tailor-made to fit your business.

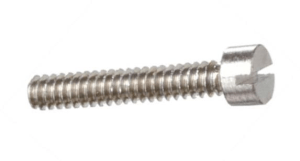

Non-counter Sunk Screw Heads

The bulk of custom screws today have non-counter sunk screw heads. This type of screw head protrudes and is fully exposed when installed on a surface. The head shape of these screws doesn’t have an angle. Consequently, you don’t need to countersink them. Most of the custom screws have this type of screw heads, and they include binding screws, domed, button, cheese, hex, flange, square and truss heads, and many more.

Pan Head

Among the many types of screws, the most common is the pan head screw. These may also be referred to as round head screws. A Philips drive is the most common driver in a pan head, but they may have a slotted drive, or 6-lobe/Torx drive, Pozi Drive, or others. The head is shaped like an upside-down frying pan, which gives it it’s name.

Flat Head

Also called countersunk, a flat head screw is tapered on the underside of the head in order to lie flush with the material it is driven into. The term “countersunk” means the flat head of the screw is flush with (or lower than) the material’s surface.

Button Head

Sometimes called a button socket screw, this rounded head most commonly has a hexagonal drive hole to accommodate an Allen wrench or hex key. However, they can also be supplied with 6-Lobe/Torx drives.The most common metals in button head screws are alloy and stainless steel, but they can also be made of titanium or aluminum.

Socket Cap Head.

This type of screw has a cylindrical shaped head with a hex recess that can be tightened with a socket wrench driver. It is available in a variety of sizes and finishes, and some are designed for outdoor applications. The socket cap head screw is most commonly used in industrial applications.

Wafer Head / Ultra-Thin Head.

Wafer head or ultra-thin head screws, used in electronic devices, are also called micro-profile, slim-head, or ultra-low head screws. Its purpose is to allow a nearly flat external surface without a countersink, making low-profile designs possible.

Pancake Head / Thin Head

This low-profile, rounded-head screw head is about two-thirds the height of a standard rounded head screw.

Undersized Pan Head

This driven head has a flat or slightly domed profile to provide a large mating surface area for a firm hold, even with enlarged holes. It allows a trim finish for decorative applications and minimizes the risk of something catching on the screw head when the item is used.

Pan Washer Head

This head type is a combination of a screw and a washer. The head can be circular or hexed, and has a washer built onto the head to increase its diameter, prevent overdriving into softwoods, while providing a maximum bearing surface. It also helps the screw remain firmly in place.

Fillister Head

Fillister-head screws are raised above the surface on a flat base to keep the screwdriver from damaging the surface as the screw is tightened. Brass Fillister head screws are corrosion resistant, nonmagnetic, and electrically conductive. Nylon Fillister head screws are chemical and oil resistant, nonconductive, and lightweight.

Oval Fillister Head

Oval fillister screws are essentially the same as fillister screws, but the shape on the top of the head is rounded. These are typically paired with a slotted drive.

Oval Flat Head

Screws with an oval flat head are desirable for fastening hinges to cabinets. They are usually available in finishes that coordinated with cabinetry hardware finishes, such as white wood or white stainless steel. Depending on the application, they may require a countersunk hole.

Cheese Head

A cheese head has cylindrical sides with a flat disc top (similar to a wheel of cheese) and a flat bearing surface. The head height is about half its diameter and typically has a slot drive. Its deeper slot capacity makes it ideal for applications requiring extra head strength, or a deeper drive socket.

Before selecting screws, you should be clear what type of screw heads you will need to utilize. Some of the factors that you should weigh before selecting a screw head

1. Type of Material

When you’re working with wood, you are better off using countersunk screws. This is because these screws don’t split the wood when drilling, as opposed to the non-counter sunk ones. Other materials, such as metal, may utilize combination heads.

2. Aesthetics

If you do not want the screw heads to be visible on the surface, countersunk screws fit the bill. It is easy to conceal countersunk screw heads using head screw covers, commonly known as beauty caps. If you choose the wrong type of screws for your business, it may negatively impact on the overall look of your business.

3. Safety

For instance, if you manufacture furniture, you want to avoid protruding screw heads on the surface. It’s easy for an unsuspecting person to get deep scratches from a protruding screw head. Countersunk screw heads are best suited when making both office and domestic furniture. These include baby cribs, conference tables, and office chairs.

4. Pick the Right Screw Drivers

Even after selecting the right custom screws for your business, you’ll need to get the right tools to install the screw. There are many types of screwdrivers that you can use, but some of the most common ones include Phillips, slotted, spanner, hex socket, and square screwdrivers. If you don’t utilize a screwdriver that fits the screw head, it may cause head damage. The screw head may strip or crack, which makes the screw useless, and may water down the overall quality of your business.

The success of your business will be influenced by the type of the selected screw head shape. It is important to weigh all the factors that come into play before picking a custom screw. An experienced custom screw manufacturer will give you best screw head options to meet your requirements.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Games

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness

- IT, Cloud, Software and Technology