In healthcare, breathable films are used in the production of surgical gowns, masks, and other protective garments

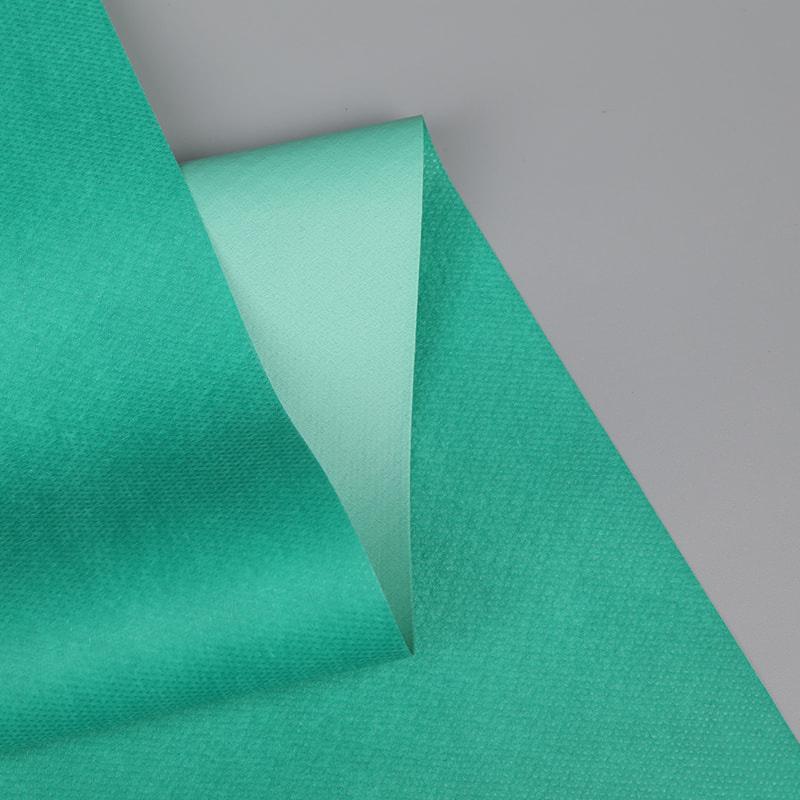

Breathable films have found a niche in the realm of personal protective equipment (PPE), offering a balance between safety and comfort that is essential in high-stress environments. These films are engineered to be impermeable to liquids and particulates while allowing air and moisture vapor to escape, making them ideal for applications where both protection and breathability are required.

In healthcare, breathable films are used in the production of surgical gowns, masks, and other protective garments. They provide a barrier against bloodborne pathogens and other contaminants while allowing healthcare workers to breathe easily and maintain comfort during long shifts. This reduces the risk of heat stress and improves overall wearer compliance with PPE protocols.

For industrial workers, breathable films are used in the manufacturing of chemical-resistant suits and gloves. These films protect against hazardous chemicals and solvents while allowing sweat to evaporate, preventing the wearer from becoming too hot or uncomfortable. This is particularly important in industries where workers are exposed to chemicals for extended periods.

In addition to their practical benefits, breathable films also contribute to the overall comfort and performance of athletic wear. They are used in the production of moisture-wicking fabrics that keep athletes dry and comfortable during high-intensity activities.

In summary, breathable films offer a range of benefits in PPE, enhancing both the safety and comfort of workers across various industries. As technology advances, the development of more advanced breathable films will likely lead to even greater improvements in PPE design and functionality.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Games

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness

- IT, Cloud, Software and Technology