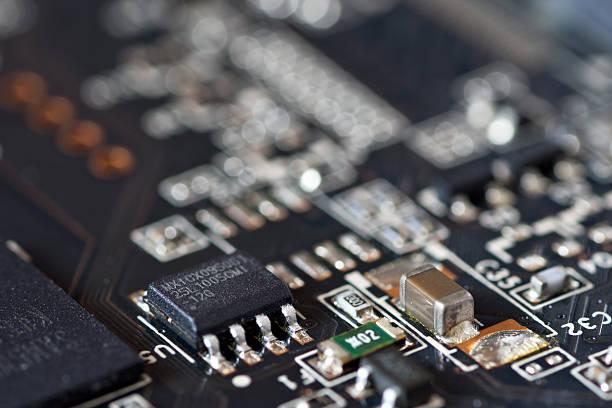

ASIC Chip - Revolutionizing The Semiconductor

An Application-Specific Integrated Circuit (ASIC) is a microchip customized for a particular use rather than intended for general-purpose use. ASIC chips are designed, developed, and manufactured for very specific applications like mobile processors, graphic cards, network routers etc. They offer advantages over general-purpose processors as they can be customized for higher performance, very low power consumption, and lower production costs for large volume manufacturing.

Hardware Customization for Optimized Performance

ASIC chips are designed and optimized for specific algorithms or computational tasks. Their internal architecture and circuit design is customized at the transistor level for the intended application. This allows achieving peak performance levels that are not possible with general purpose CPUs or GPUs. For example, some ASICs are designed for cryptomining and achieve unprecedented hash rates. Machine vision ASICs used in cameras have dedicated hardware for computer vision tasks like object recognition. Such hardware-level customization results in significantly higher performance and efficiency compared to general solutions.

Lower Power Consumption through Hardware Tailoring

Since ASIC Chip chips are built specifically for the target application, their hardware can be designed prudently while eliminating unnecessary components. This leads to very low power requirements compared to general processors. For battery-powered devices, ASICs allow extending battery life as they consume only the exact amount of power needed for the intended functions. For example, ASICs powering always-on voice assistants or IoT sensors consume mere microwatts of power which has enabled a new generation of low-power always-on solutions. Their dedicated design approach facilitates building ultra-low-power chips.

Mass Production Yields Greater Economies of Scale

Once developed, ASIC chips can be mass-produced using advanced semiconductor fabrication facilities. This allows benefiting from economies of scale where per-unit production costs drop substantially with volume. ASIC foundries are capable of producing hundreds of millions of identical chips annually. The specialized nature of ASICs also simplifies testing and validation processes compared to general chips. All these factors contribute to significantly lower chip production costs per unit in high volumes making ASICs an attractive solution for consumer electronics. This is a big advantage over general CPUs whose per-unit costs remain high even at scale.

Flexibility Through Software Programmability

While ASIC chips have dedicated hardware optimized for specific tasks, many also offer some degree of software programmability. This flexibility allows modifying or enhancing their behavior through software and firmware updates. Some popular ASIC examples like mobile processors come with programmable microcontrollers and other logic that can be updated over the air. Such software flexibility extends the usable life of ASICs and helps adapt to evolving requirements. It also provides a middle ground between fixed-function ASICs and fully programmable CPUs.

Broader Applicability Across Industries

Thanks to their performance, power, and cost advantages - ASICs are increasingly being used across many industries beyond just computers, consumer electronics, and communications. Fields like automotive, industrial IoT, avionics, healthcare, retail, and more are adopting ASIC solutions. Application domains range from advanced driver-assistance systems to industrial automation, telematics control units, medical imaging, digital signage, embedded vision, surveillance, payment processing etc. As embedded systems become more pervasive, specialized ASICs will play a bigger role in productivity and efficiency gains.

ASIC chips are revolutionizing the semiconductor industry by offering massively optimized solutions for specialized applications. Their hardware-level customization allows unprecedented levels of performance within minimal power budgets. Combined with the economies of scale in high-volume manufacturing, ASICs provide a highly cost-effective solution compared to general-purpose CPUs. While initially confined to few niches, ASIC technology is now spreading across industries and transforming how specialized tasks are accomplished more efficiently. ASICs will continue to replace general processors in embedded systems through their compelling advantages.

Get More Insights: ASIC Chip

For More Insights Discover the Report In language that Resonates with you

About Author:

Priya Pandey is a dynamic and passionate editor with over three years of expertise in content editing and proofreading. Holding a bachelor's degree in biotechnology, Priya has a knack for making the content engaging. Her diverse portfolio includes editing documents across different industries, including food and beverages, information and technology, healthcare, chemical and materials, etc. Priya's meticulous attention to detail and commitment to excellence make her an invaluable asset in the world of content creation and refinement.

(LinkedIn- https://www.linkedin.com/in/priya-pandey-8417a8173/)

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Jocuri

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Alte

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness

- IT, Cloud, Software and Technology