Harnessing the Benefits of EB Welding for Sustainable Manufacturing

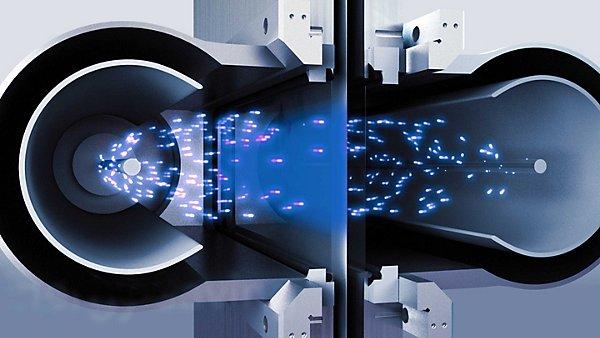

The drive toward sustainable manufacturing has created a need for technologies that enhance efficiency, reduce waste, and support environmentally conscious practices. Electron Beam (EB) welding has emerged as a transformative solution, offering unmatched precision, durability, and sustainability. By leveraging a high-energy electron beam in a vacuum environment, EB welding ensures defect-free joins while minimizing material waste and energy consumption.

In this article, we’ll explore the benefits of EB welding, its applications in sustainable manufacturing, and how it is shaping a greener future for industries like aerospace, automotive, and renewable energy. For a comprehensive guide to EB welding, visit benefits of EB welding.

Understanding EB Welding in Sustainable Manufacturing

EB welding is a high-precision process that uses a focused beam of electrons to join materials. It operates in a vacuum, eliminating impurities and ensuring clean, strong welds. This precision reduces waste, energy use, and production time, aligning with the goals of sustainable manufacturing.

Key Benefits of EB Welding for Sustainability

1. Reduced Material Waste

Traditional welding techniques often generate significant material waste, especially when working with advanced or expensive materials. EB welding uses only the material necessary for the joint, minimizing excess and reducing scrap.

- Example: Aerospace manufacturers save on high-cost titanium by using EB welding for lightweight, high-performance components.

2. Energy Efficiency

EB welding consumes less energy than traditional welding methods due to its focused heat application. By directing energy precisely where it is needed, EB welding minimizes heat loss and reduces overall energy usage.

- Benefit: Lower operational costs and a reduced carbon footprint.

3. Enhanced Durability for Long-Lasting Products

Products manufactured with EB welding feature high-quality, defect-free joints that extend their lifespan. This reduces the need for replacements and repairs, contributing to resource conservation.

- Example: Wind turbine components welded with EB technology maintain their integrity for decades under harsh environmental conditions.

4. Minimal Heat-Affected Zones (HAZ)

EB welding’s precision ensures minimal heat-affected zones, preserving the mechanical properties of surrounding materials. This reduces the risk of thermal damage and enhances product reliability.

- Benefit: Improved material utilization and fewer production defects.

5. Compatibility with Advanced Materials

EB welding excels at joining advanced and dissimilar materials, enabling manufacturers to optimize designs for performance and sustainability. This flexibility supports the development of lighter, more efficient products.

- Example: Automotive manufacturers use EB welding to combine lightweight aluminum with high-strength steel for fuel-efficient vehicles.

6. Scalability for High-Volume Production

EB welding systems can be scaled for high-volume manufacturing while maintaining consistent quality. This makes it ideal for industries focused on sustainable mass production.

- Benefit: Efficient, eco-friendly manufacturing at scale.

Applications of EB Welding in Sustainable Manufacturing

1. Renewable Energy

EB welding supports the production of durable components for wind turbines, solar panels, and geothermal systems. Its ability to join advanced materials ensures these systems operate efficiently and sustainably.

- Use Case: Heat exchangers in geothermal energy systems benefit from EB welding’s precision and durability.

2. Aerospace

The aerospace industry relies on EB welding to create lightweight, high-strength components that reduce fuel consumption and emissions. Its precision minimizes material waste, further supporting sustainability.

- Use Case: Aircraft fuselages and turbine blades are welded using EB technology for optimal performance and efficiency.

3. Automotive

In the push for greener vehicles, EB welding enables the production of lightweight, fuel-efficient cars and electric vehicles (EVs). It supports the joining of dissimilar metals, improving performance and sustainability.

- Use Case: EV battery enclosures and structural components are manufactured with EB welding for enhanced durability and efficiency.

4. Medical Devices

The medical industry benefits from EB welding’s ability to produce defect-free, biocompatible components. This ensures long-lasting implants and devices, reducing waste and supporting patient safety.

- Use Case: Titanium implants and pacemakers are welded with EB technology for reliability and longevity.

5. Defense

EB welding enhances the durability and sustainability of military equipment by reducing material waste and energy consumption during production.

- Use Case: Titanium-steel joints in armored vehicles are welded using EB technology for maximum strength and weight efficiency.

Why EB Welding Is Ideal for Sustainability Goals

1. Alignment with Circular Economy Practices

By reducing waste and extending product lifespans, EB welding supports circular economy principles. It helps manufacturers use resources efficiently and responsibly.

2. Lower Carbon Footprint

EB welding’s energy-efficient process reduces emissions associated with production, aligning with global sustainability targets.

3. Design Flexibility

The ability to join advanced materials and create complex geometries allows for innovative, lightweight designs that improve energy efficiency and performance.

Innovations Enhancing the Benefits of EB Welding

AI and Automation

Artificial intelligence is being integrated into EB welding systems to optimize energy use, reduce waste, and ensure consistent quality.

IoT Monitoring

Real-time monitoring with IoT-enabled sensors allows for precise control and adjustments, improving efficiency and reducing defects.

Advanced Materials Development

Ongoing research into welding-compatible alloys is expanding EB welding’s applications in sustainable manufacturing.

Hybrid Systems

Combining EB welding with additive manufacturing enhances its capabilities, supporting innovative, eco-friendly designs.

Why Choose EB Welding for Sustainable Manufacturing?

The benefits of EB welding make it an essential tool for manufacturers committed to sustainability. Its ability to reduce waste, conserve energy, and produce long-lasting, high-quality components ensures it meets the demands of eco-conscious industries.

Explore More About EB Welding

For more information on how EB welding supports sustainable manufacturing, visit benefits of EB welding. This guide provides detailed insights into the technology, its applications, and its advantages.

Conclusion

Electron Beam welding is revolutionizing sustainable manufacturing by delivering precision, efficiency, and reliability. Its ability to minimize waste, conserve energy, and produce durable components makes it an invaluable tool for industries aiming to reduce their environmental impact.

As global industries increasingly prioritize sustainability, the benefits of EB welding will continue to grow, driving innovation and efficiency. By adopting EB welding, manufacturers can meet their sustainability goals while achieving excellence in quality and performance.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Spiele

- Gardening

- Health

- Startseite

- Literature

- Music

- Networking

- Andere

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness

- IT, Cloud, Software and Technology