Nickel Metal Hydride Battery: Innovative Battery Technology for Sustainable Energy Storage

Nickel Metal Hydride Battery Chemistry

The nickel metal hydride (NiMH) battery utilizes a chemical reaction between nickel oxide hydroxide in the positive electrode and a hydrogen-absorbing alloy in the negative electrode to generate electricity. Like other rechargeable batteries, the cathode is composed of nickel oxyhydroxide (NiOOH) while the anode contains a hydrogen-storing metal alloy, typically composed of rare earth metals such as lanthanum, cerium, neodymium or praseodymium. During discharge, hydrogen is released from the anode and reacts with oxygen in the nickel oxyhydroxide cathode to produce water and release electrons which flow through the external circuit, powering devices. The reaction is reversible, allowing the battery to be recharged many times by passing current in the opposite direction.

History and Development of NiMH Batteries

Nickel Metal Hydride Battery was invented in the early 1980s as an alternative to the toxic and environmentally unfriendly NiCd battery. It was designed to have better capacity, slower self-discharge, reduced toxicity and no memory effect. Early NiMH batteries suffered from relatively short cycle life and high self-discharge rates. Major improvements were made in the 1990s with the development of AB5-type negative electrodes containing mischmetal. This significantly enhanced the battery's cycle life and shelf life by reducing hydrogen absorption/desorption kinetics. Modern NiMH batteries can now deliver hundreds of charge-discharge cycles with low rates of self-discharge, making them popular for consumer use in cordless power tools, electric vehicles, and other portable devices.

Performance Characteristics of NiMH Batteries

Compared to other rechargeable batteries like NiCd and lead-acid, NiMH batteries offer several advantages in terms of performance:

- Higher energy density - NiMH batteries can store up to 2-3 times more charge per unit weight than NiCd batteries of the same size. This extends runtimes.

- No memory effect - Unlike NiCd batteries, NiMH batteries do not exhibit reduced capacity if partially discharged between charges. They can be charged at any time without losing effectiveness.

- Low self-discharge - When fully charged and not in use, NiMH batteries lose only around 5-10% of their charge per month at room temperature. Self-discharge is much lower than sealed lead-acid batteries.

- Better peak power performance - NiMH batteries are capable of delivering high currents for power tools, cameras, etc. and undergo less voltage depression under heavy loads compared to other rechargeable batteries.

- Environmental friendliness - NiMH batteries do not contain toxic heavy metals like mercury (in alkaline batteries) or cadmium (in NiCd batteries). They can also be safely disposed of without special precautions.

Applications of NiMH Batteries

Owing to their relatively high energy density, lack of memory effect, low self-discharge, and non-toxic nature, NiMH batteries have become widely adopted in numerous portable electronic applications:

- Cordless power tools - Drills, saws, sanders, lawn mowers, and other power tools are a major application due to their peak power performance and long runtimes.

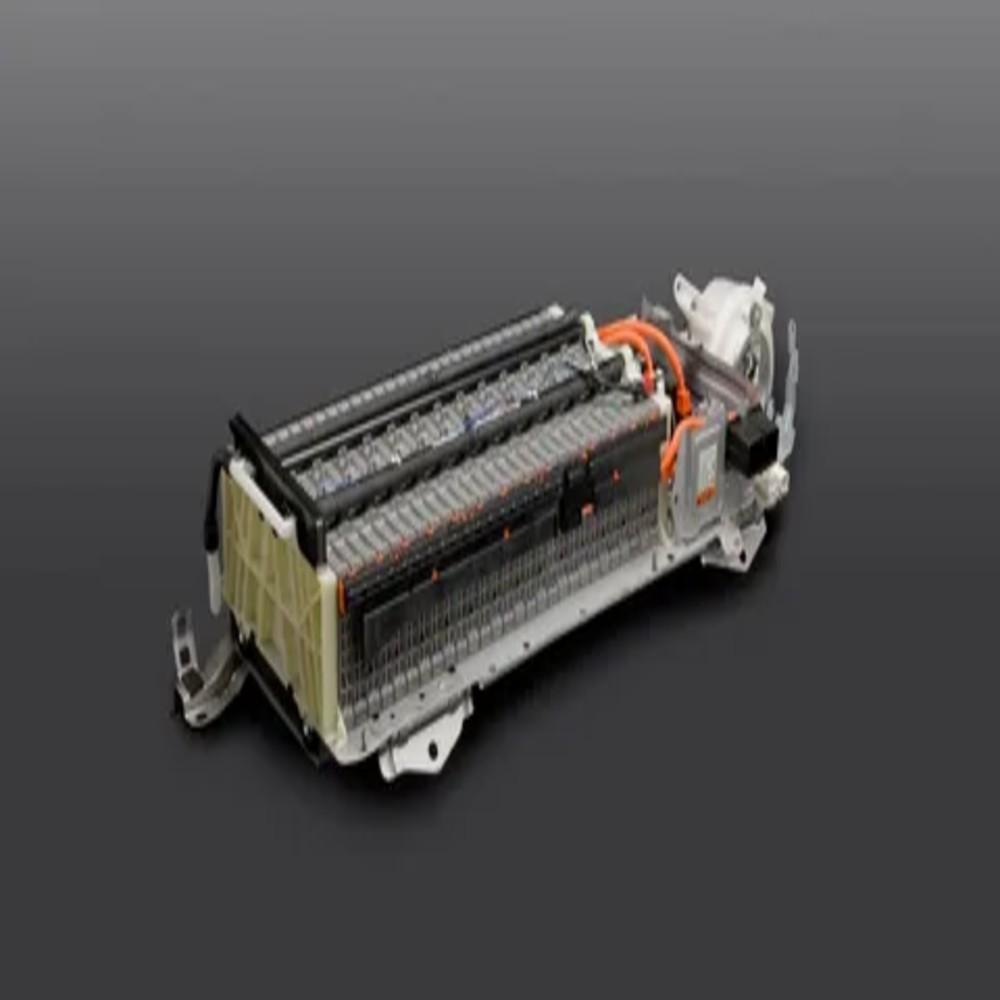

- HEVs and EVs - Many hybrid electric vehicles like the Toyota Prius use NiMH batteries in their energy storage systems for their efficiency.

- Cameras - Both professional-grade and consumer camcorders and digital cameras commonly use NiMH battery packs.

- Toys and remote controls - Battery-powered toys, remote controls for audio/video equipment, and other small electronics frequently rely on AAA or AA NiMH batteries.

- Laptop computers - Earlier laptop models used NiMH batteries which provided greater capacity than contemporary NiCad packs.

- Flashlights - Many high-capacity flashlights are powered by rechargeable NiMH battery packs for extended operation.

- Medical devices - Mobility aids, toothbrushes, shavers, and other personal care appliances may use NiMH batteries safely.

Advancements in Nickel Metal Hydride Battery Technology

Research continues to improve the NiMH battery in various ways. Nanomaterials are being explored to improve electrode surface areas and shorten ion diffusion lengths for faster charging. Alloy compositions are being optimized to reduce hydrogen depletion and enhance cycle life. Additives like cobalt and gallium help regulate internal resistance and inhibit capacity fade mechanisms. Solid-state electrolytes may eventually replace the aqueous potassium hydroxide electrolyte currently used. And nanostructured composite electrodes hold promise for achieving even higher energy densities. The future of NiMH battery technology remains bright as refinements build upon the remarkable accomplishments already achieved with this versatile and environmentally-friendly energy storage solution.

In dive into the technology and versatility of nickel metal hydride (NiMH) batteries, the workhorse of the rechargeable battery world. Explore how these robust and reliable power sources offer high energy density, excellent cycle life, and enhanced safety features, making them an ideal choice for applications ranging from consumer electronics to renewable energy storage.

Explore More Related Article On- Amino Acid Market

For Deeper Insights, Find the Report in the Language that You want.

About Author:

Vaagisha brings over three years of expertise as a content editor in the market research domain. Originally a creative writer, she discovered her passion for editing, combining her flair for writing with a meticulous eye for detail. Her ability to craft and refine compelling content makes her an invaluable asset in delivering polished and engaging write-ups.

(LinkedIn: https://www.linkedin.com/in/vaagisha-singh-8080b91)

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- الألعاب

- Gardening

- Health

- الرئيسية

- Literature

- Music

- Networking

- أخرى

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness

- IT, Cloud, Software and Technology