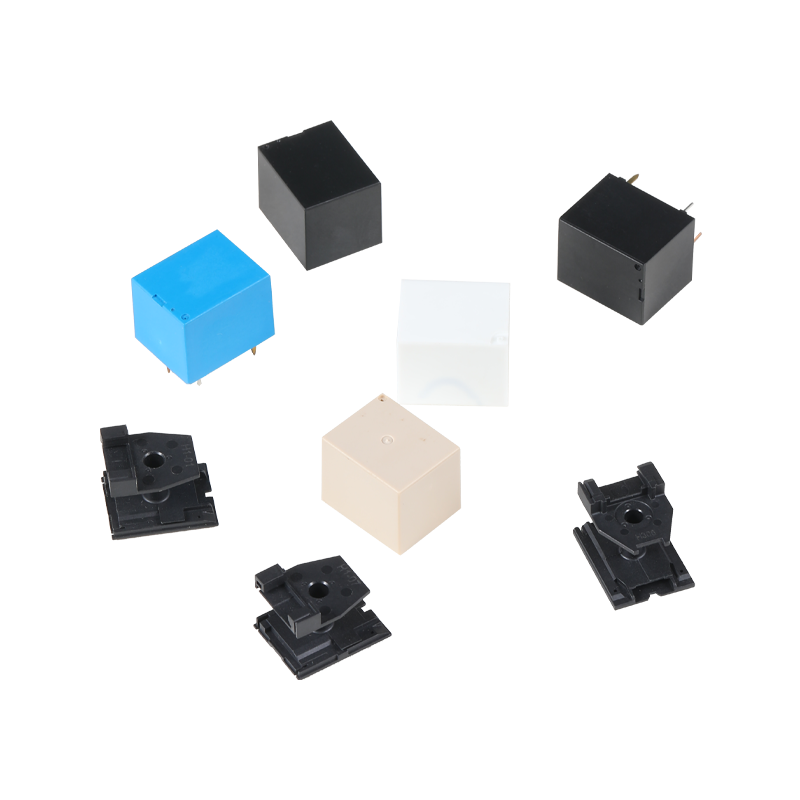

Small molded parts are ubiquitous in our daily lives, found in everything from electronic devices to automotive components. These parts are typically produced using injection molding, a process where molten material is injected into a mold cavity and allowed to cool and solidify. The precision of this method allows for the creation of intricate details and high-quality finishes. Small molded parts are often used in applications where size, weight, and material properties are critical, such as in the aerospace, medical, and consumer electronics industries.

Dual shot injection molding, also known as two-shot molding, is a process that involves injecting two different materials into a single mold to create a part with two distinct layers. This technique allows for the combination of materials with different properties, such as soft and hard plastics, to create parts that are both functional and aesthetically pleasing. The dual material approach can enhance the part's durability, comfort, and appearance. For instance, a handle might have a soft grip made of one material and a structural body made of another, providing both comfort and strength.