Robotic Grippers in the Manufacturing Industry: Revolutionizing Production through 3D Printing

Introduction

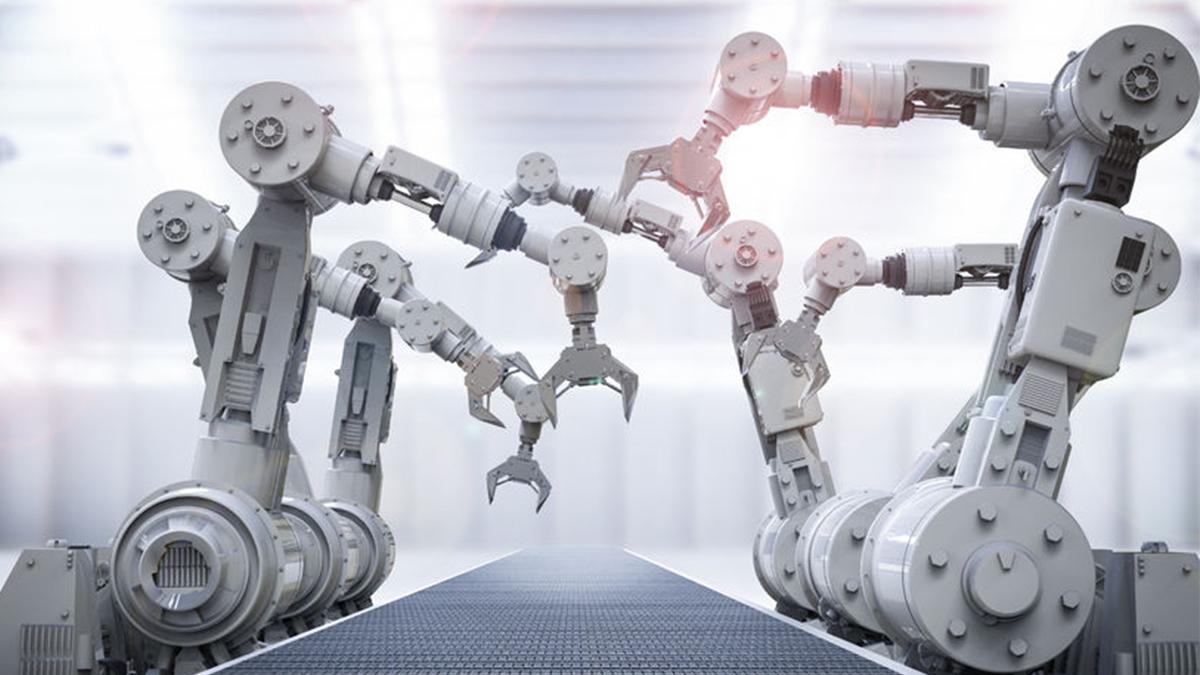

The manufacturing industry is experiencing a significant transformation, driven by advancements in robotics and automation. Among these innovations, robotic grippers play a pivotal role, enabling machines to perform complex tasks with precision and efficiency. This article explores the impact of robotic grippers on manufacturing, with a particular focus on how 3D printing is revolutionizing their design and production through rapid prototyping and customization.

Understanding Robotic Grippers

Robotic grippers are essential components of robotic arms, designed to grasp, manipulate, and release objects. They come in various types, including mechanical, vacuum, and soft grippers, each suited for different applications. In manufacturing, robotic grippers are employed in tasks such as assembly, packaging, quality inspection, and material handling.

The Importance of Robotic Grippers in Manufacturing

Robotic grippers enhance productivity, reduce labor costs, and improve product quality. Their ability to work alongside human operators creates a collaborative environment where both can optimize their strengths. As manufacturing processes become more complex and demand for customization increases, the need for innovative gripper designs has never been greater.

The Role of 3D Printing in Robotic Gripper Development

Rapid Prototyping: Accelerating Design Cycles

3D printing, or additive manufacturing, has emerged as a game-changer in the development of robotic grippers. Traditionally, designing and producing grippers involved lengthy manufacturing processes, including machining and assembly. 3D printing allows engineers to create prototypes quickly and cost-effectively.

- Faster Design Iteration: With 3D printing, engineers can iterate designs rapidly, testing various configurations and materials without the delays associated with traditional manufacturing. This speed enables teams to refine their ideas and reach optimal designs much faster.

- Cost-Effective Prototyping: Producing a prototype through traditional methods can be costly, especially for low-volume projects. 3D printing significantly reduces costs by minimizing material waste and eliminating the need for specialized tooling.

Customization and Personalization

One of the most significant advantages of 3D printing is its ability to facilitate customization. In manufacturing, the demand for bespoke solutions is increasing, and robotic grippers are no exception.

- Tailored Solutions: Different tasks require different gripper designs. 3D printing allows manufacturers to create custom grippers that perfectly fit the specific needs of their production line. Whether it's adapting to unique product shapes or optimizing for particular handling tasks, customization ensures efficiency and effectiveness.

- Material Variety: 3D printing technology enables the use of a wide range of materials, including plastics, metals, and composites. This versatility allows manufacturers to select materials based on the specific requirements of their applications, whether it's strength, flexibility, or heat resistance.

Advanced Features Enabled by 3D Printing

Complex Geometries and Lightweight Designs

3D printing opens up new possibilities for designing grippers with complex geometries that would be difficult or impossible to achieve with traditional manufacturing techniques.

- Lightweight Structures: By utilizing lattice structures and topology optimization, engineers can create grippers that are both strong and lightweight. This reduces the overall weight of robotic arms, improving their speed and energy efficiency.

- Enhanced Functionality: Advanced designs can incorporate features such as built-in sensors or compliance mechanisms that allow for better handling of fragile or irregularly shaped objects. This level of sophistication enhances the versatility of robotic grippers in various manufacturing contexts.

Integration of Smart Technologies

The intersection of 3D printing and robotics is paving the way for smarter manufacturing solutions. By integrating sensors and actuators directly into the gripper design, manufacturers can create more responsive and intelligent systems.

- Real-Time Feedback: Smart grippers can provide real-time data on grip force, position, and orientation, allowing for more precise control. This data can be used to adjust the gripper’s behavior dynamically, improving accuracy in delicate operations.

- Increased Autonomy: With integrated smart technologies, robotic systems can operate with greater autonomy, reducing the need for human intervention and minimizing errors. This shift is particularly valuable in high-volume production environments where consistency and speed are critical.

Case Studies: 3D Printing in Robotic Gripper Applications

Case Study 1: Automotive Manufacturing

In the automotive industry, the need for efficient assembly processes is paramount. A leading automotive manufacturer implemented 3D-printed robotic grippers to handle various components, from small electronic parts to large panels.

- Result: By rapidly prototyping and testing different gripper designs, the company reduced assembly time by 30% and improved the accuracy of part placement, leading to higher-quality finished products.

Case Study 2: Electronics Assembly

A company specializing in electronics faced challenges in handling delicate components without causing damage. They turned to 3D printing to develop custom soft grippers tailored to the unique shapes and fragility of their products.

- Result: The soft grippers allowed for gentle handling, reducing breakage rates by 40%. The ability to quickly iterate designs further enabled the company to adapt to new product lines with minimal downtime.

Challenges and Considerations

While 3D printing offers numerous advantages, there are challenges that manufacturers must consider:

- Material Limitations: Not all materials suitable for traditional manufacturing are available for 3D printing. Manufacturers must carefully select materials that meet performance criteria while also being compatible with 3D printing processes.

- Scale and Speed: For high-volume production, traditional manufacturing methods may still be more efficient in terms of speed and cost. Manufacturers need to evaluate the trade-offs between the flexibility of 3D printing and the economies of scale offered by conventional methods.

- Technical Expertise: Developing effective 3D-printed grippers requires specialized knowledge in both robotics and additive manufacturing. Investing in training and development is essential to leverage these technologies fully.

The Future of Robotic Grippers and 3D Printing

As the manufacturing landscape continues to evolve, the integration of 3D printing and robotic grippers is likely to become even more prevalent. Future advancements may include:

- Increased Automation: The combination of 3D printing and robotics will lead to even greater levels of automation in manufacturing, enabling fully automated production lines capable of handling diverse tasks with minimal human oversight.

- Sustainability: As manufacturers seek to reduce waste and improve sustainability, 3D printing offers a more efficient production method that can lower material usage and energy consumption.

- Collaborative Robots (Cobots): The rise of collaborative robots will drive further innovation in gripper design, emphasizing safety and efficiency in environments where humans and robots work side by side.

Conclusion

Robotic grippers are an essential element of modern manufacturing, and the advent of 3D printing is transforming their development. With capabilities for rapid prototyping, customization, and integration of advanced technologies, 3D printing is reshaping the way manufacturers approach robotic gripper design. As industries continue to seek innovative solutions for increased efficiency and productivity, the synergy between robotics and additive manufacturing will play a crucial role in the future of manufacturing.

See the full article: https://www.nextmsc.com/blogs/overview-of-robotic-grippers-market

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Spellen

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness

- IT, Cloud, Software and Technology