Automotive Lightweight Materials Market Restraints: Challenges Impacting Adoption Across Global Automotive Industry

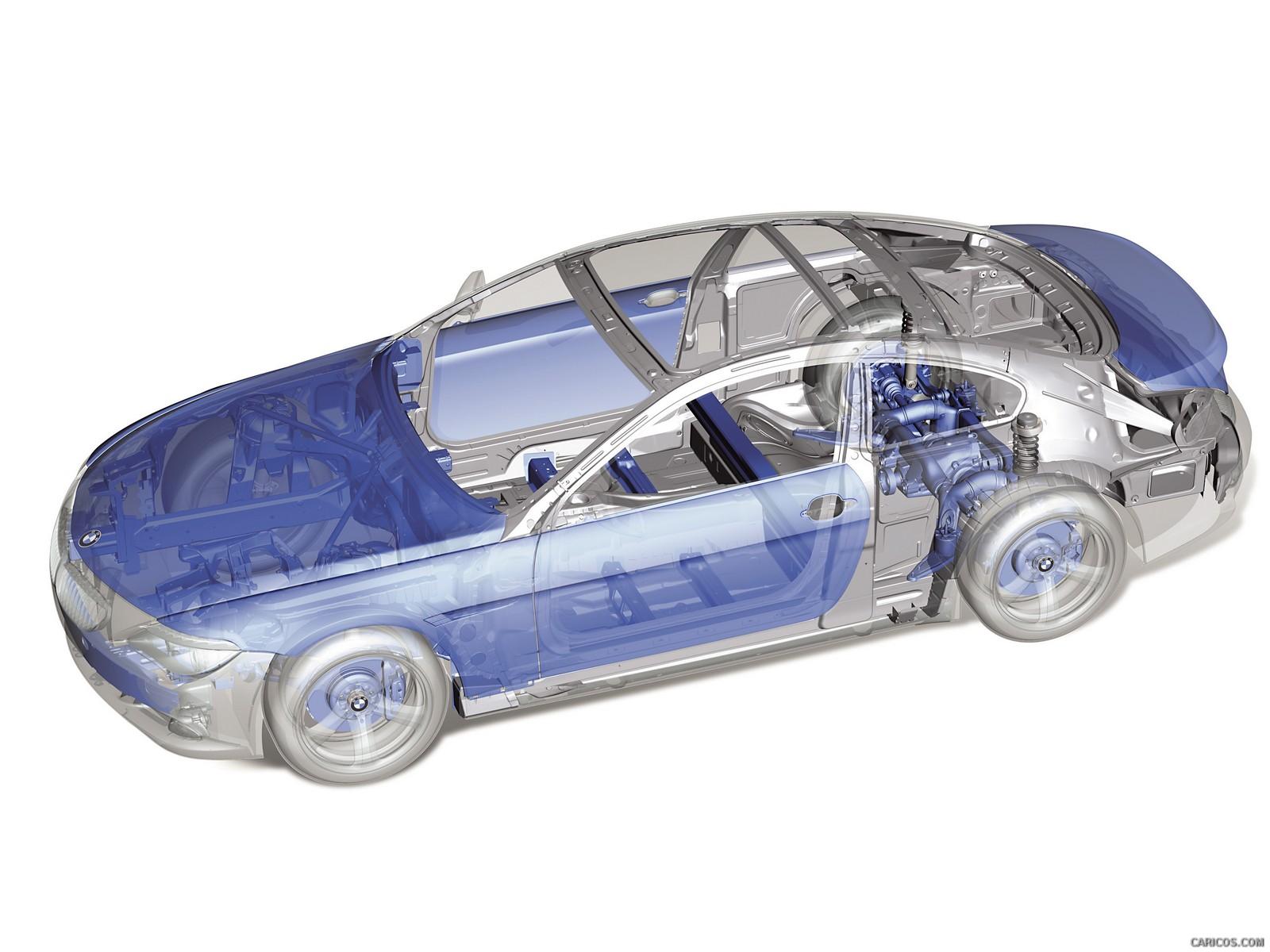

The automotive lightweight materials market is pivotal in driving sustainability and fuel efficiency in the global automotive sector. Lightweight materials, such as aluminum, high-strength steel, magnesium alloys, and composites, have gained widespread attention due to their ability to reduce vehicle weight while maintaining structural integrity. Despite their potential, the market is not without challenges. Several restraints are slowing down the growth and adoption of these materials, impacting manufacturers, suppliers, and consumers alike.

1. High Production Costs

The primary restraint in the automotive lightweight materials market is the high cost associated with production. Advanced materials like carbon fiber and titanium are expensive to manufacture and process, making them less accessible for mass-market vehicles. While premium automakers can afford to integrate such materials into luxury and performance vehicles, mainstream manufacturers struggle to justify the additional costs.

For instance, carbon fiber, despite its superior strength-to-weight ratio, involves energy-intensive production processes and specialized equipment. These costs trickle down to consumers, often deterring them from purchasing vehicles with such advanced materials.

2. Limited Availability and Resource Constraints

The availability of raw materials like magnesium, rare earth elements, and high-grade composites poses a significant challenge. Regions with limited access to these resources face supply chain bottlenecks, increasing production costs and lead times. Moreover, geopolitical factors can exacerbate supply issues, as certain countries dominate the production of critical materials, making the market vulnerable to trade disputes and export restrictions.

3. Manufacturing and Technological Barriers

The integration of lightweight materials into automotive design requires sophisticated manufacturing processes and technologies. Many manufacturers face difficulties in adapting their existing production lines to accommodate new materials. Welding, bonding, and forming lightweight metals and composites demand advanced techniques that traditional manufacturing methods cannot provide.

For example, joining dissimilar materials, such as aluminum and steel, often results in technical challenges that require costly solutions, slowing adoption rates. Small and medium-sized manufacturers, in particular, struggle to invest in the necessary equipment and training.

4. Regulatory and Safety Concerns

While lightweight materials are critical for meeting stringent fuel efficiency and emission standards, they can introduce new regulatory and safety challenges. For example, the use of certain composites may raise concerns about recyclability and environmental impact. Governments and regulatory bodies are increasingly emphasizing circular economy principles, requiring manufacturers to develop sustainable end-of-life solutions for these materials.

Additionally, lightweight materials must meet crash safety standards, which can be difficult to achieve without compromising other vehicle aspects. Manufacturers must strike a delicate balance between reducing weight and maintaining passenger safety.

5. Consumer Perception and Demand

Consumer perception remains a hurdle for the market. Many consumers are unaware of the benefits of lightweight materials, such as improved fuel efficiency and reduced emissions. This lack of awareness can hinder demand, particularly in cost-sensitive markets where price outweighs performance benefits.

Furthermore, some consumers associate lightweight materials with reduced durability, despite advancements in material strength and resilience. Overcoming these misconceptions is crucial for widespread adoption.

6. Environmental and Recycling Challenges

While lightweight materials contribute to lower emissions during vehicle operation, their production and recycling processes often have a higher environmental footprint. For instance, the energy-intensive production of carbon fiber and aluminum can offset the environmental benefits of reduced fuel consumption.

Moreover, recycling certain materials, like composites, remains a complex and costly process, limiting their appeal in a market increasingly driven by sustainability goals. Developing cost-effective recycling solutions is essential to overcoming this restraint.

Conclusion

The automotive lightweight materials market faces significant challenges that must be addressed to unlock its full potential. High production costs, resource constraints, technological barriers, regulatory concerns, and consumer perception issues collectively hinder growth. However, these restraints also present opportunities for innovation. Industry stakeholders must invest in research and development, sustainable practices, and consumer education to overcome these challenges and drive the market forward. Addressing these restraints will be critical for achieving the automotive industry's long-term goals of sustainability, efficiency, and safety.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Jocuri

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Alte

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness

- IT, Cloud, Software and Technology